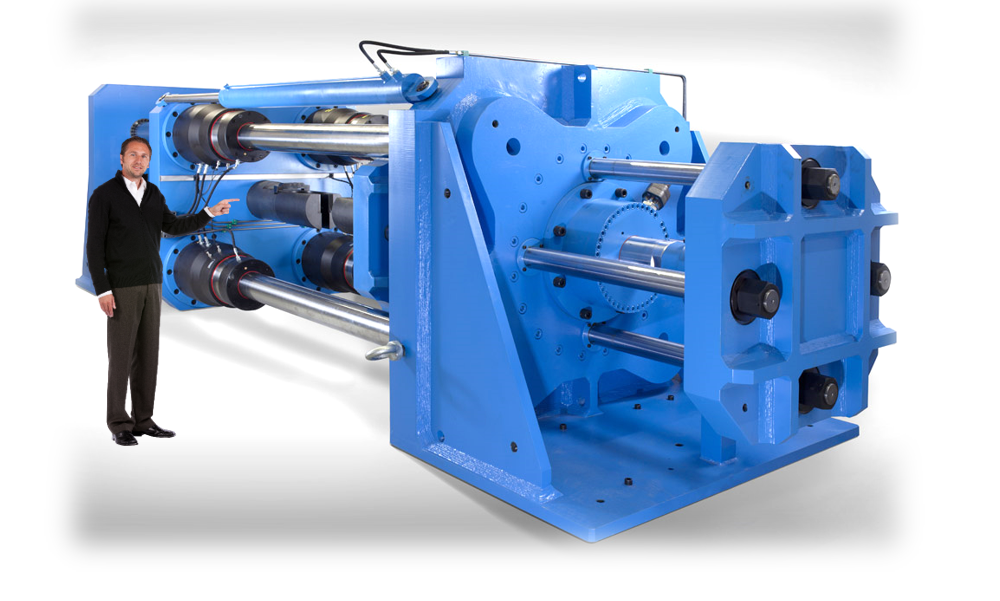

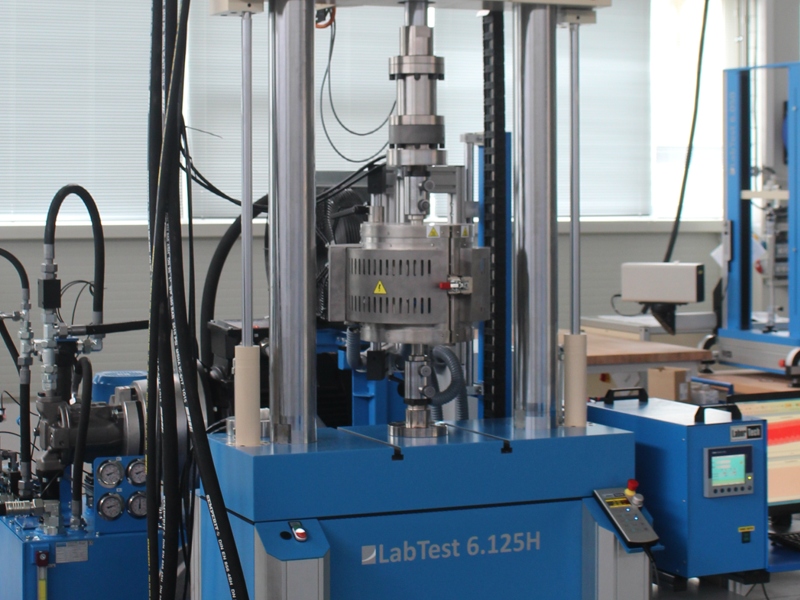

H.6 – HORIZONTAL DYNAMIC TESTING MACHINES UP TO 10 MN

Horizontal dynamic testing machines series H. 6 in tensile design up to 10MN are designed for mechanical testing of high-strength materials in dynamic mode with freely adjustable clamping length of the working space. This range of machines is characterized by high frame rigidity and mechanical resistance. The H.6 series machines are designed for testing construction ropes, high-strength chains, etc. The range of a given machine depends on the dynamic stroke and frequency. A specific test set is derived from these parameters, which consists of a test frame, a servo-hydraulic cylinder and a hydraulic unit of the HAD series with HALT 18 – SIEMENS diagnostics.

Download:

MEZERA

We offer technical solutions – WE ARE PROFESSIONALS

Individual approach to the design of fixtures and the machine itself …

MEZERA

Key features

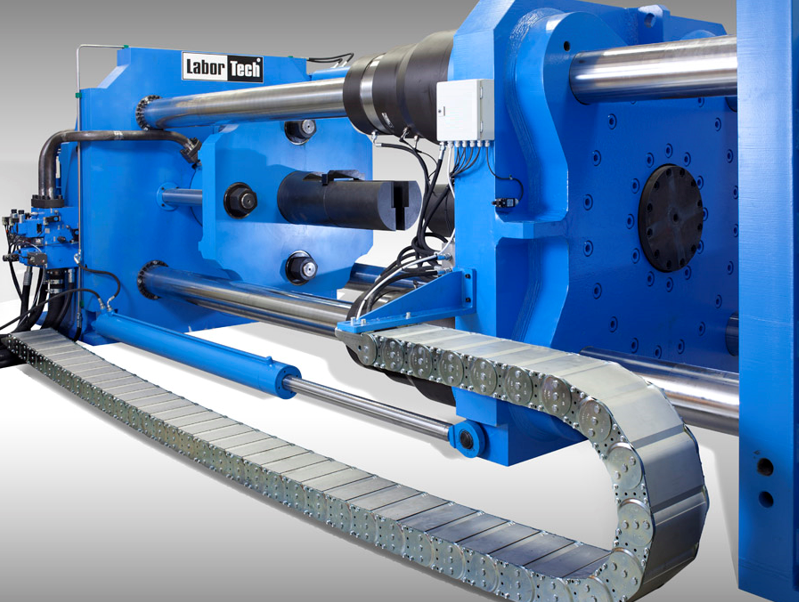

- Robust horizontal four-column design with high rigidity, mechanical resistance and durability.

- The ergonomics of the workspace and the sufficient width of the workspace allow for trouble-free handling of samples and accessories.

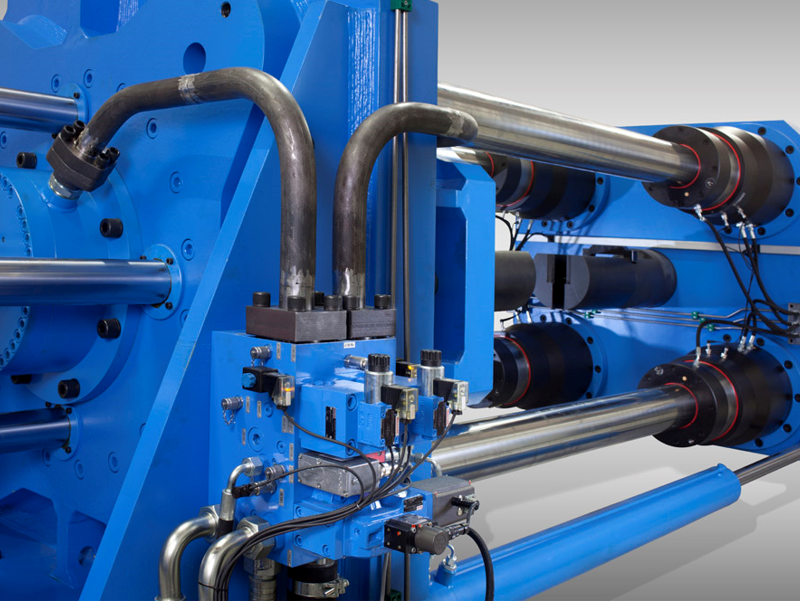

- Integrated servo cylinder in the machine base for pressures of 210 or 280 bar.

- Test control by proportional or servo valve with the possibility of control in the power and position loop.

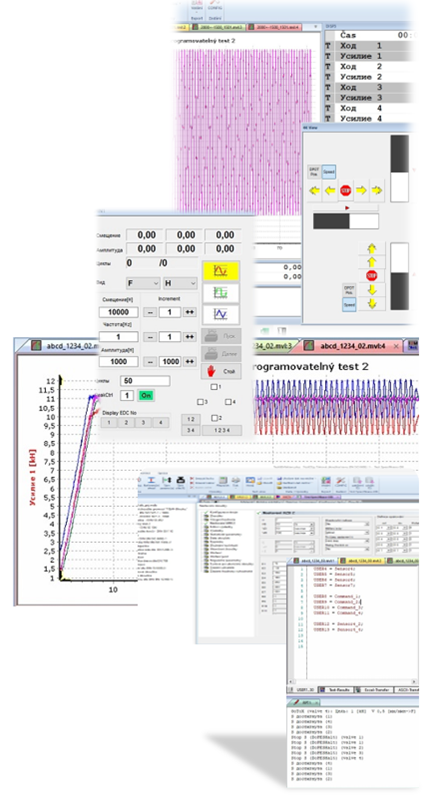

- Complete test evaluation and control is provided by Test & Motion material testing software – DYNPACK.

- Load cells working in the accuracy class according to EN ISO 7500-1, ASTM E4 with the possibility of linearization.

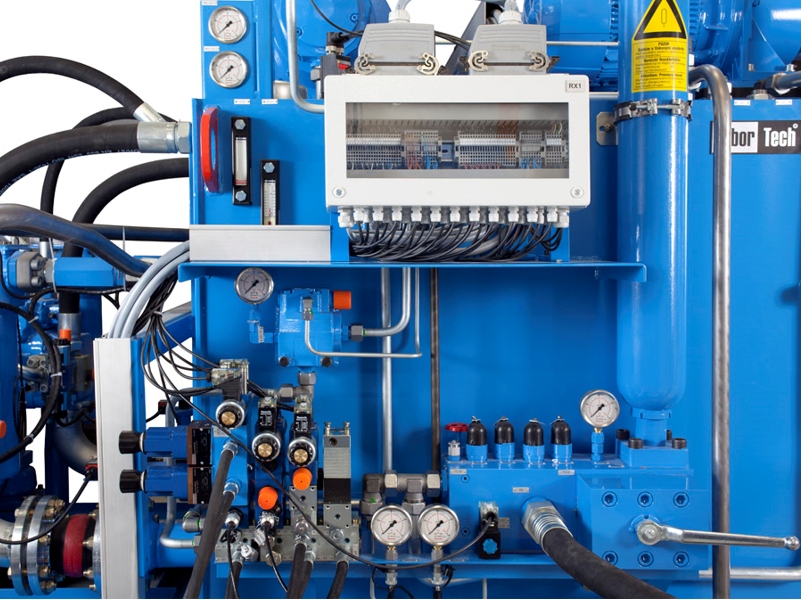

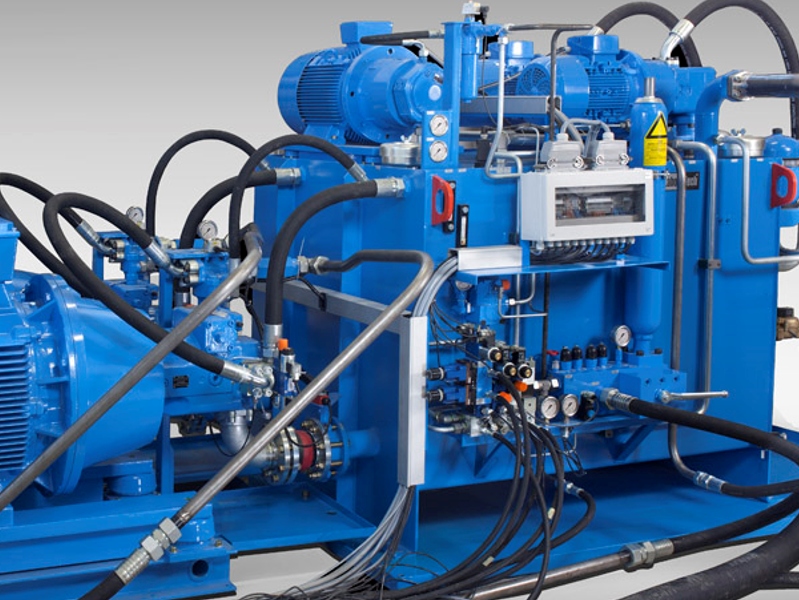

- Powerful compact hydraulic units of the HAD series with low noise level thanks to the PAC system.

- HALT 18 hydraulic unit diagnostics controlled by TOUCH LCD SIEMENS as standard.

- The H.6 series machines comply with all the above-mentioned EC directives on machinery and equipment and work in accordance with the new safety functions according to EN ISO 13850-SIL 1 / PL.

- The machine is controlled by measuring and control electronics of the EDCi series with a sampling frequency of 10 kHz. Analog signal resolution level ± 250,000 divisions (20 ms).

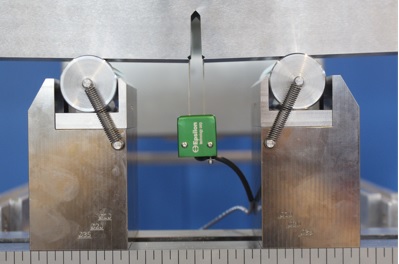

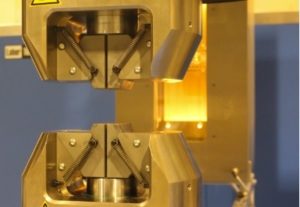

- Integration of special jigs or hydraulic grips with wedge clamping.

- High-precision tests with a special horizontal temperature chamber or high-temperature furnace.

Tested parts

Horizontal dynamic testing machines series H. 6 in tensile design up to 10MN are ideal for dynamic testing of these parts:

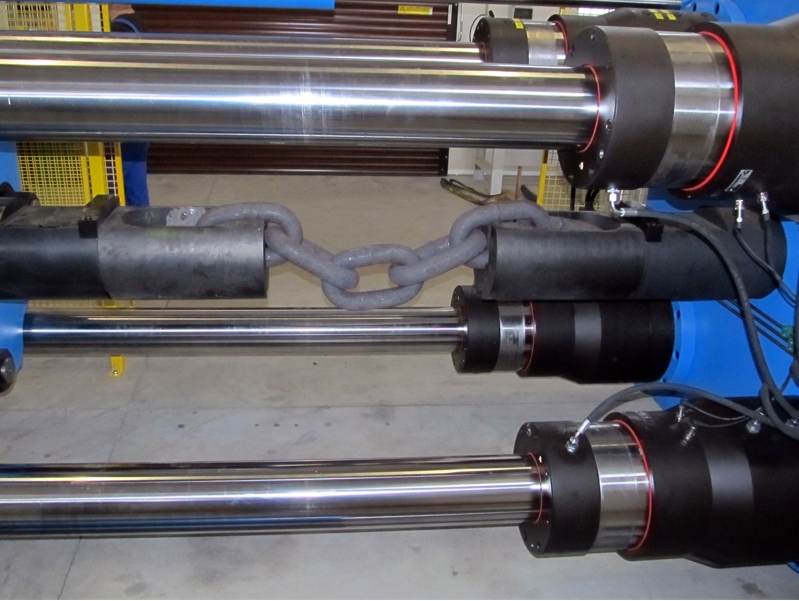

- High-strength chains

- Mining chains

- Suspension chains

- Technical chains

- Protective chains

- Traction chains, etc.

according to standards: DIN 20637, DIN 22 258-1, EN 13411-2, EN 13411-3, EN 13411-4, EN 13411-5, EN 13411-6, EN 13411-7, EN 12385-1 + A1, EN 1492-2 atd.

Fixtures design

Each component tested on H.6 series horizontal dynamic testing machines shall have 100% test fixtures that have:

- High accuracy

- Coaxiality

- Hardness

- Toughness Mechanical resistance

All grips are constructed in a 3D CAD INVERTOR with detailed diagnostics using the FEM method, manufactured and subsequently subjected to demanding testing in our testing laboratory. We guarantee the result, we are professionals.

Test evaluation

Test&Motion+ – DYNPACK – intelligent, intuitive and powerful software to help you increase productivity and testing quality in your test rooms and test labs. You can streamline, refine, and accelerate your testing and adapt your testing environment to make it easy for operators to measure the mechanical properties of materials in a dynamic single-axis or multi-axis test mode with support for EN, ISO, DIN, ASTM, and GOST standards.

Say what you want and what you expect from the software and we will do it for you.

Our specialists are able to custom design and manufacture a machine or automated system with a high degree of quality and uniqueness. When designing fixtures, optimization often begins with details and in 3D STEP formats or DWF viewers. When developing LABORTECH products, we place great emphasis on the quality, design and affordability of our products. In the design of machines and systems, we pay attention to the minimum environmental impact and ECODESIGN in accordance with the standard ČSN EN ISO 14001: 2016. We verify the accuracy, reliability, durability and mechanical resistance of our machines in a test and calibration center.

MEZERA

Do you have questions about our products?

Feel free to contact our product experts.

We look forward to your interest.

–

MEZERA

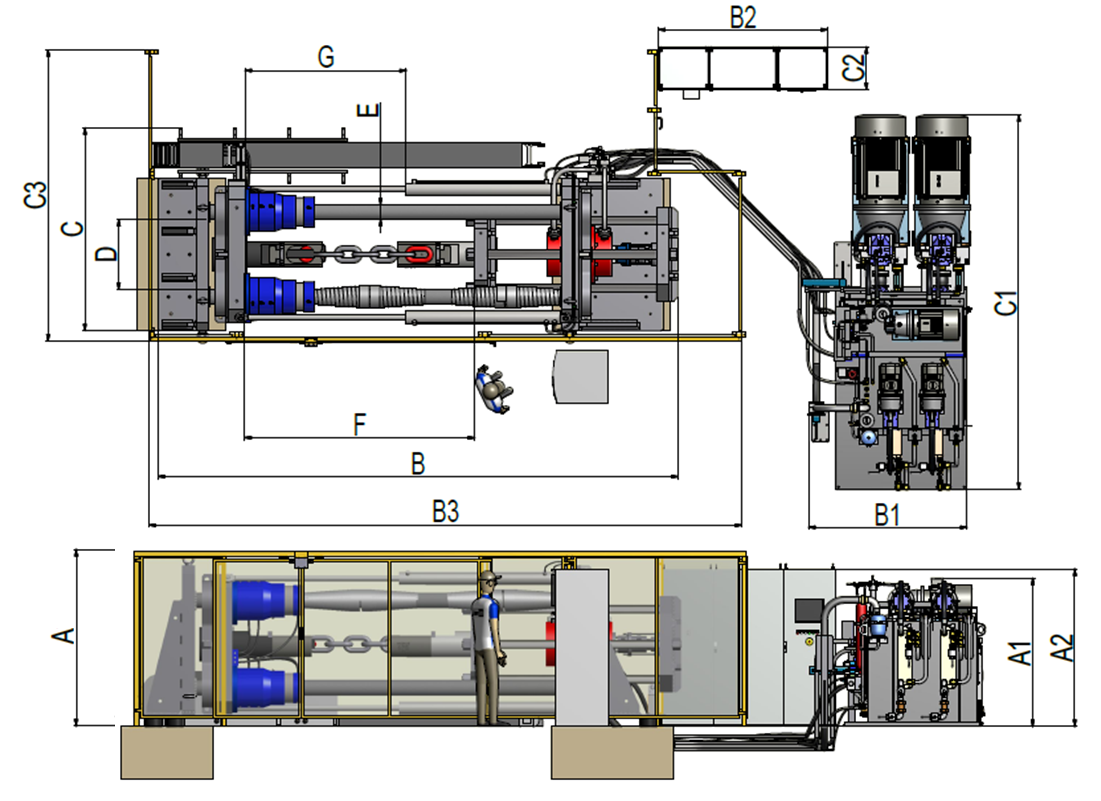

CHART OF TECHNICAL PARAMETERS series H.6 up to 4MN

- Technical data

- Product code

- Max. load

- Crossbarr adjustment

- Crossbar clamping

- Stiffness of the machine 1000 mm

- Max. frequency / stroke

- Machine height – A

- Height of Hydraulic unit – A1

- Machine width – B

- Width of Hydraulic unit – B1

- Fencing width – B3

- Machine depth – C

- Depth of Hydraulic unit – C1

- Width of working space. – D

- Rod diameter – E

- Length of workspace – F

- Transverse displacement stroke – G

- weight

- Machine power consumption

- Units

- –

- kN

- –

- –

- kN/mm

- Hz / mm

- mm

- mm

- mm

- mm

- mm

- mm

- mm

- mm

- mm

- mm

- mm

- kg

- kVA

- LabTest 6.3000H.6

- 1.08061118

- 3000

- Elektro – hydraulicky

- Elektro – hydraulicky

- 8500

- 5 / 5

- 2000

- 1700

- 6150

- 1150

- 6990

- 2400

- 1550

- 840

- 160

- 2850

- 1900

- 32100

- 300

- LabTest 6.4000H.6

- 1.08061216

- 4000

- Elektro – hydraulicky

- Elektro – hydraulicky

- 9800

- 5 / 5

- 2000

- 1700

- 6150

- 1150

- 6990

- 2450

- 1550

- 820

- 180

- 2712

- 1900

- 33200

- 300

MEZERA

Test&Motion+ – DYNPACK Software

Intuitive software for long-term dynamic tests

Test & Motion + – DYNPACK – intelligent, intuitive and powerful software that will help you increase productivity and testing quality in your test rooms and testing laboratories. You can streamline, refine, and accelerate your testing and adapt your testing environment to make it easy for operators to measure the mechanical properties of materials in a dynamic single-axis or multi-axis test mode with support for EN, ISO, DIN, ASTM, and GOST standards.