Contact

TESTING SPRING CLAMPS FOR RAIL FIXING – LABTEST 6.50H.5-TS – DYNAMIC

Basic description:

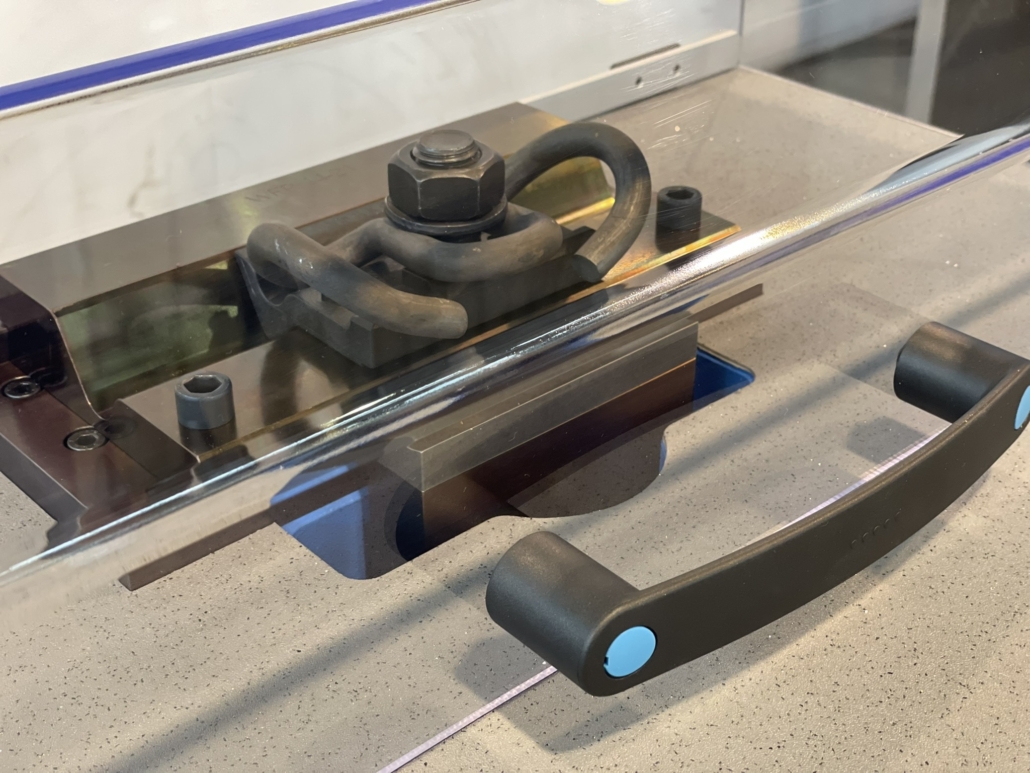

Spring Steel Rail Fastening 918 127 Rail Clips, Tension Clips, Spring Clips…

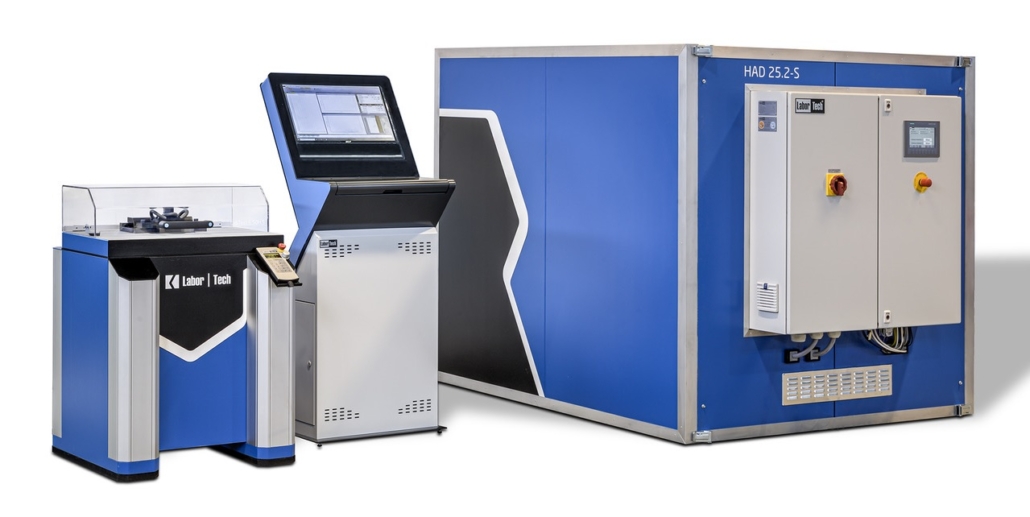

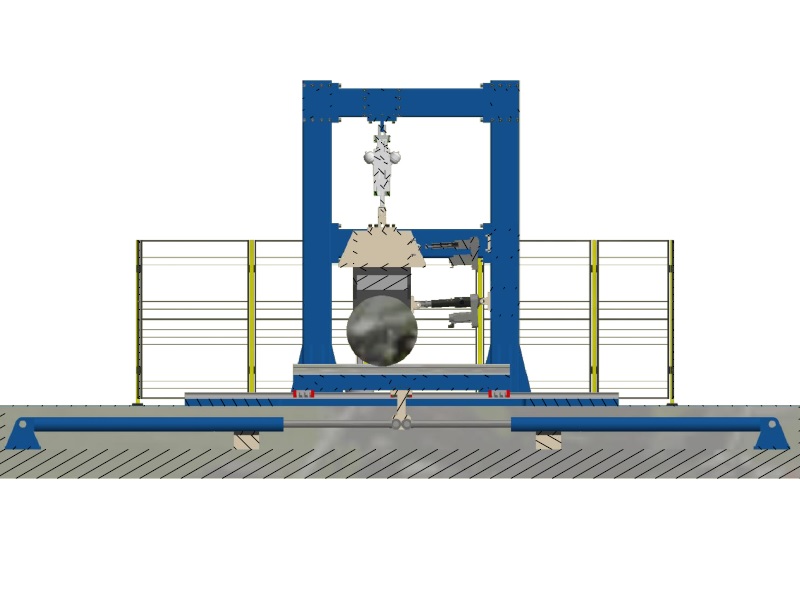

One of our top rail testing machines is the LabTest 6.50-TS. This servo-hydraulic testing machine is designed for testing clips, tension clips, and spring clips made of spring steel according to DBS 918 127 – Deutsche Bundesbahn – in static and dynamic mode including long-term fatigue tests.

Basic parameters:

Max. test force – 50kN, cylinder stroke 50 mm, max. test frequency 50Hz, hydraulic aggregate with flow rate Q=25l/min, preparation for expansion to a second workplace, protective safety cover with electronic door opening monitoring and high safety according to ČSN EN ISO 13849- 1, ČSN EN ISO 12100 and ČSN EN ISO 14120 …

Application – Standards:

Railway industry – standards DBS 918 127

Materials tested:

Rail clips, tension clips, spring clips…

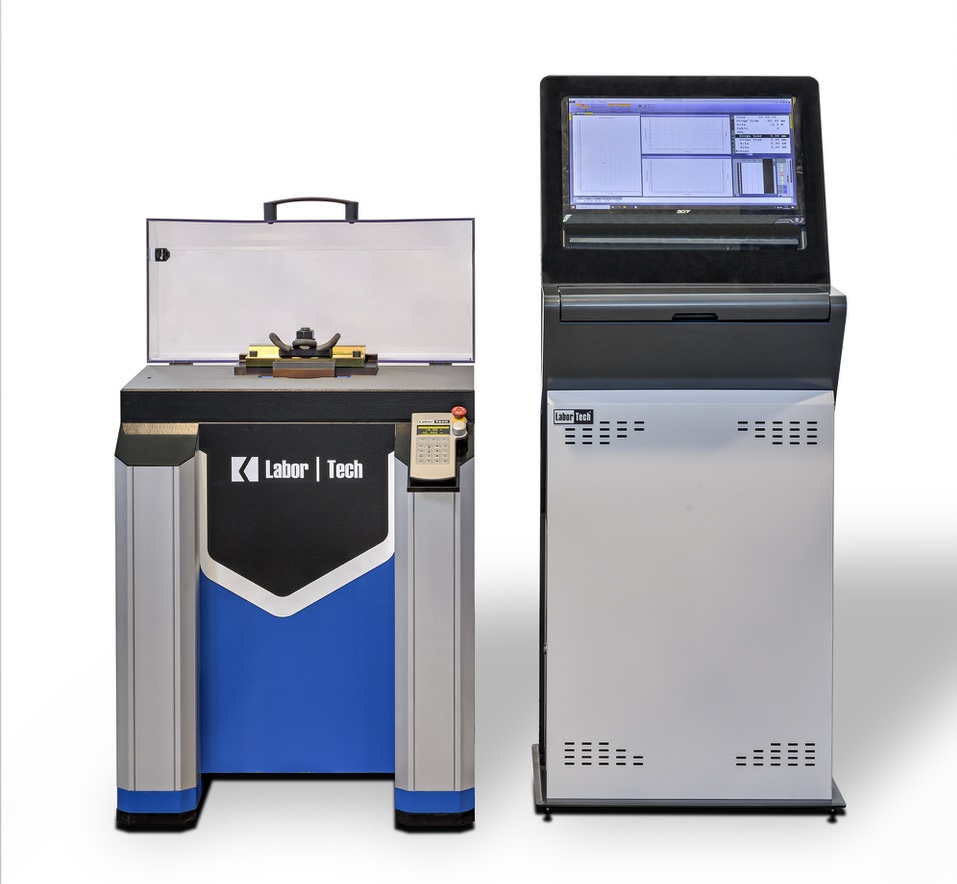

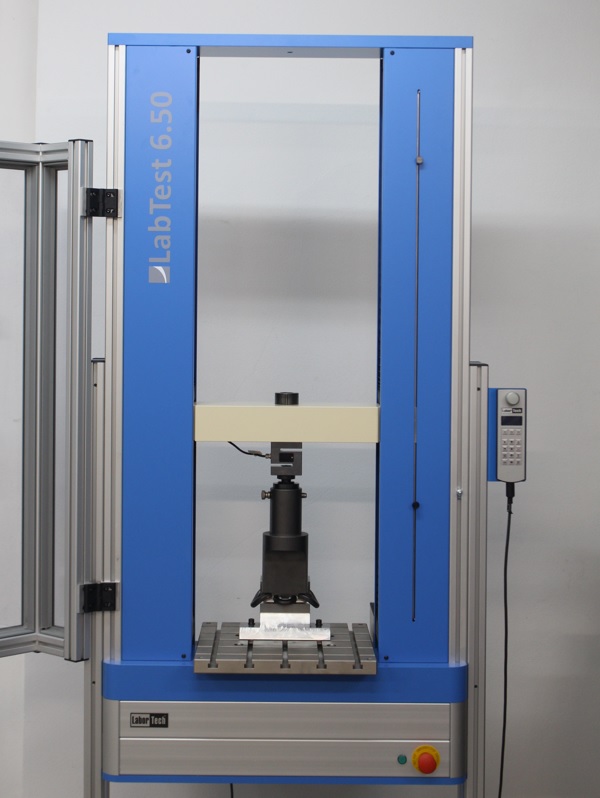

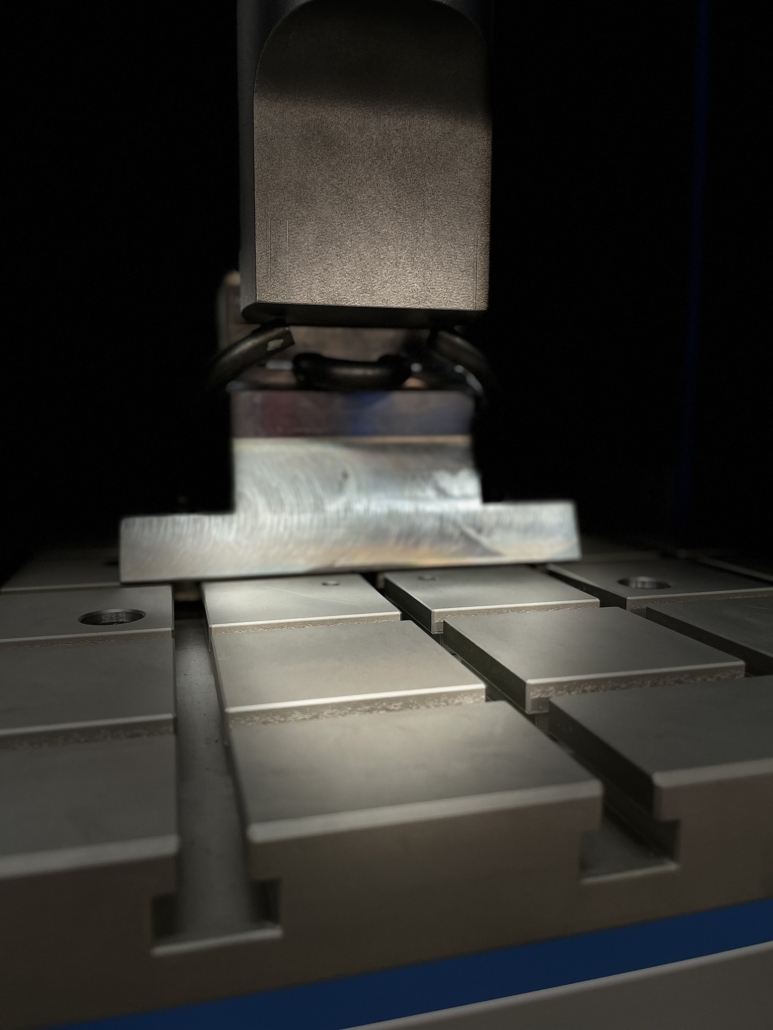

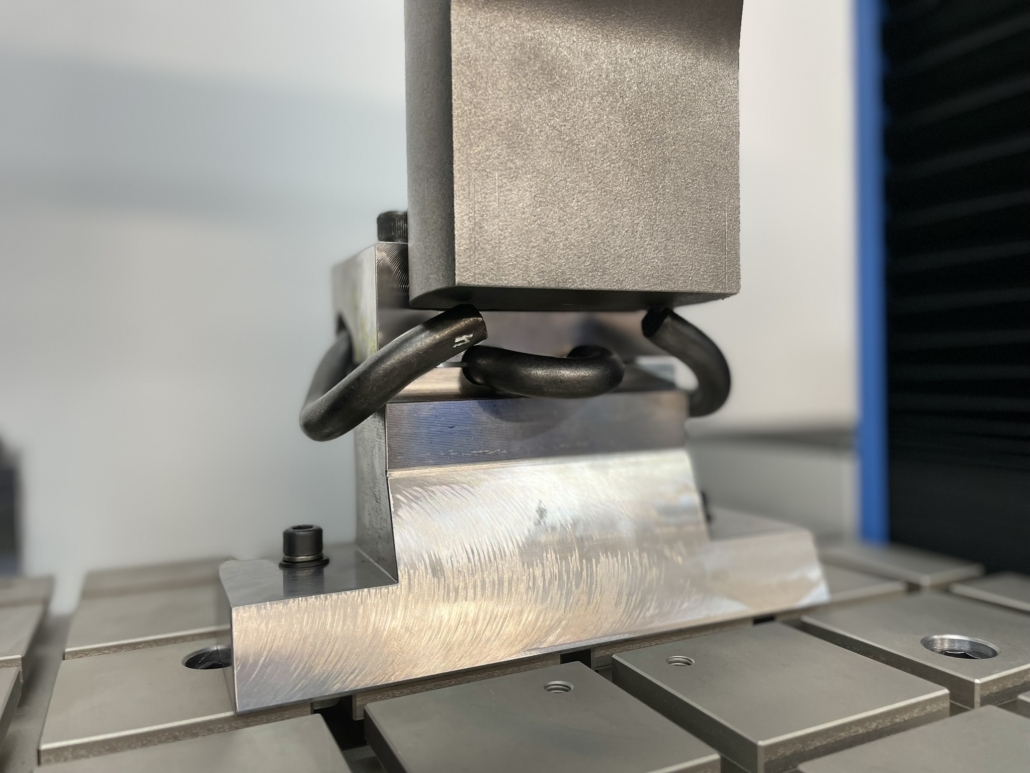

TESTING SPRING CLIPS FOR RAIL FIXING – LABTEST 6.50E.2 – STATIC

Basic description:

Spring Steel Rail Fastening 918 127 Rail Clips, Tension Clips, Spring Clips…

One of the standard testing machines for railways is an electromechanical device labeled LabTest 6.50. This electromechanical testing machine is designed to test clips, tension clips and spring clips made of spring steel according to DBS 918 127 – Deutsche Bundesbahn – in static mode including destructive tests

Basic parameters:

Max. test force – 50kN, machine stroke 1100 mm, max. test low cycle frequency 0.5Hz, integrated universal T groove plate, special hardened preparations protective safety cover with electronic monitoring of door opening and high safety according to ČSN EN ISO 13849-1, ČSN EN ISO 12100 and ČSN EN ISO 14120 …

Application – Standards:

Railway industry – standards DBS 918 127

Materials tested:

Rail clips, tension clips, spring clips…

MEZERA

“In the near future, we plan to launch the NEW dynamic testing product LABTEST 6.50H.5-TS-Dynamic mode. If you are interested in participating in the development and prototype testing of the upcoming device, do not hesitate to contact us.”

MEZERA

Contact us:

MEZERA

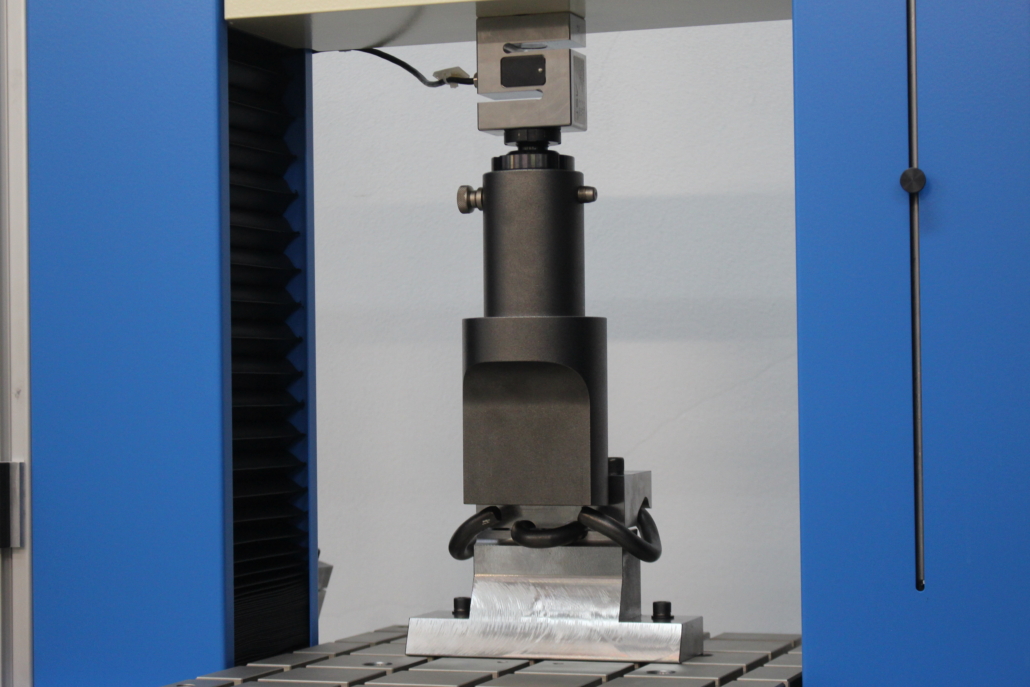

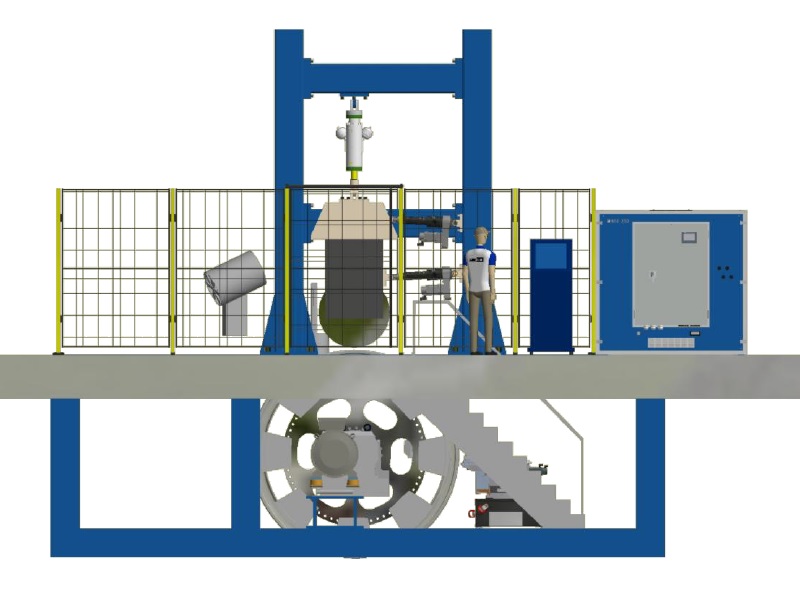

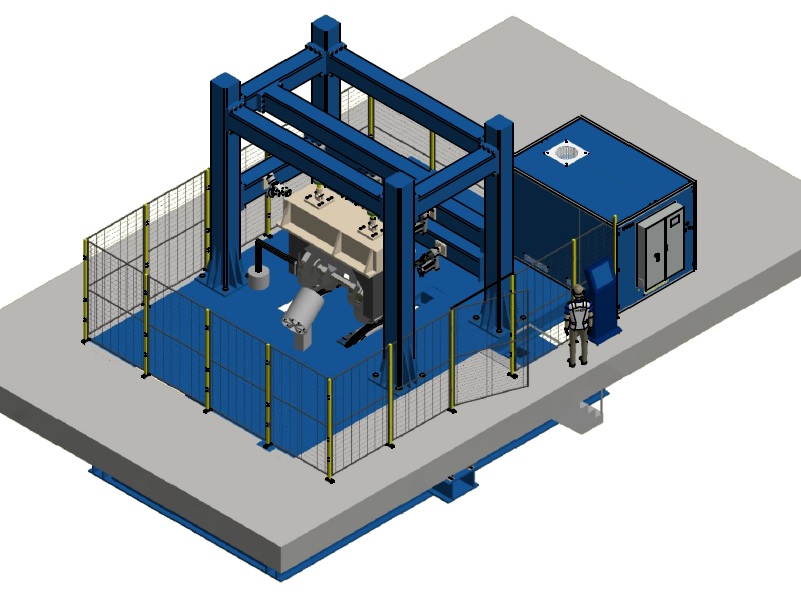

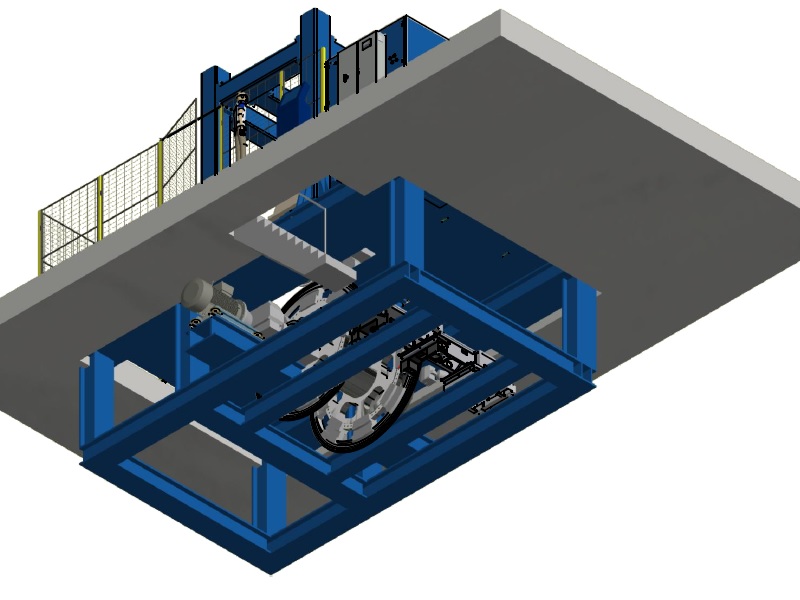

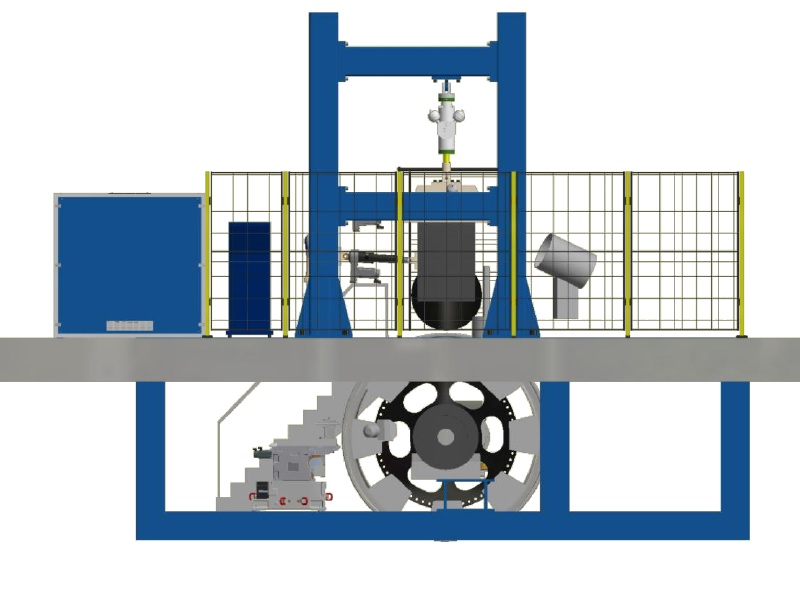

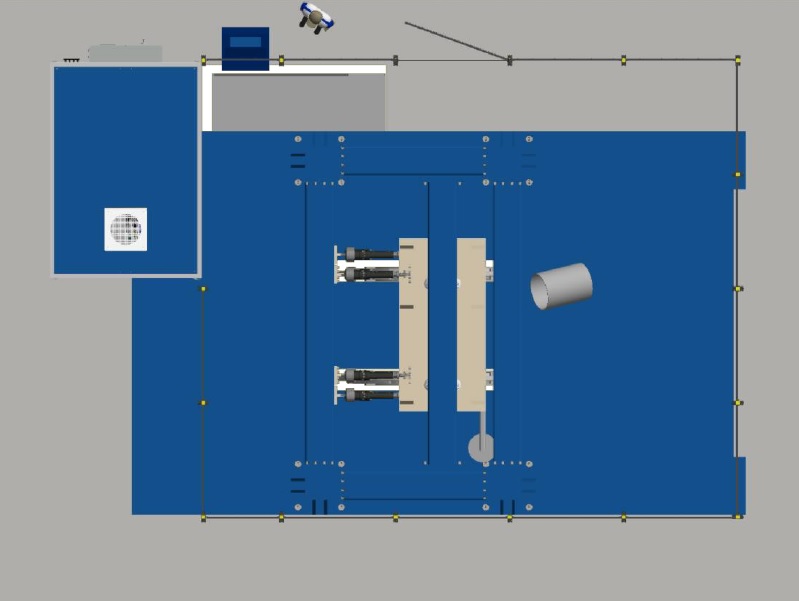

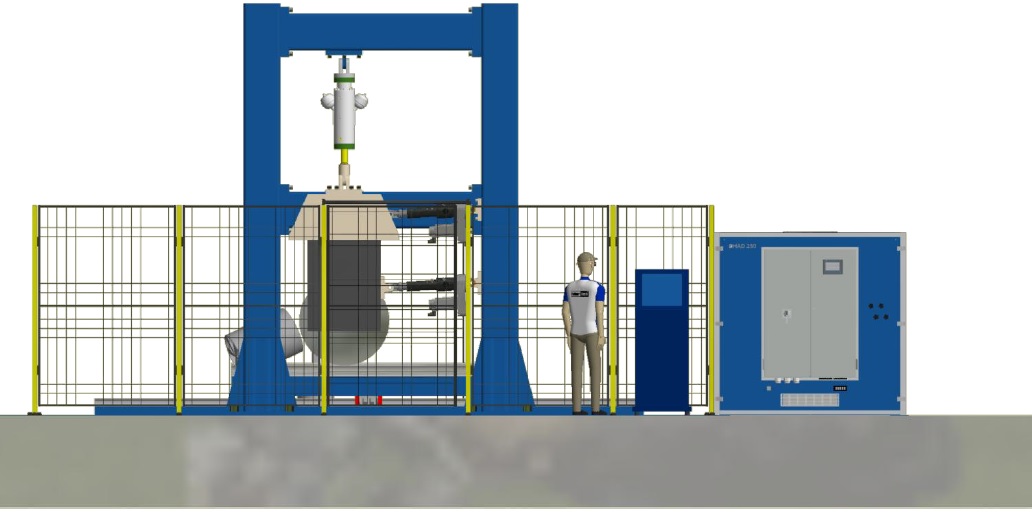

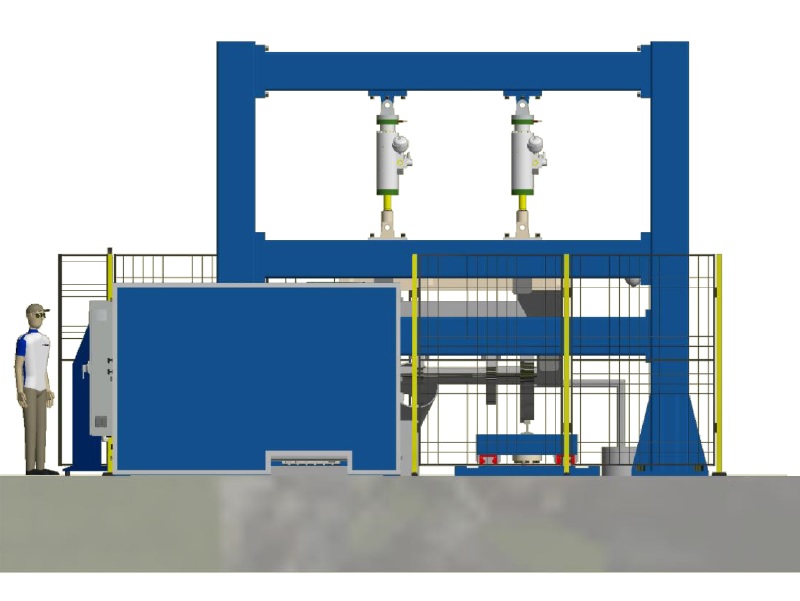

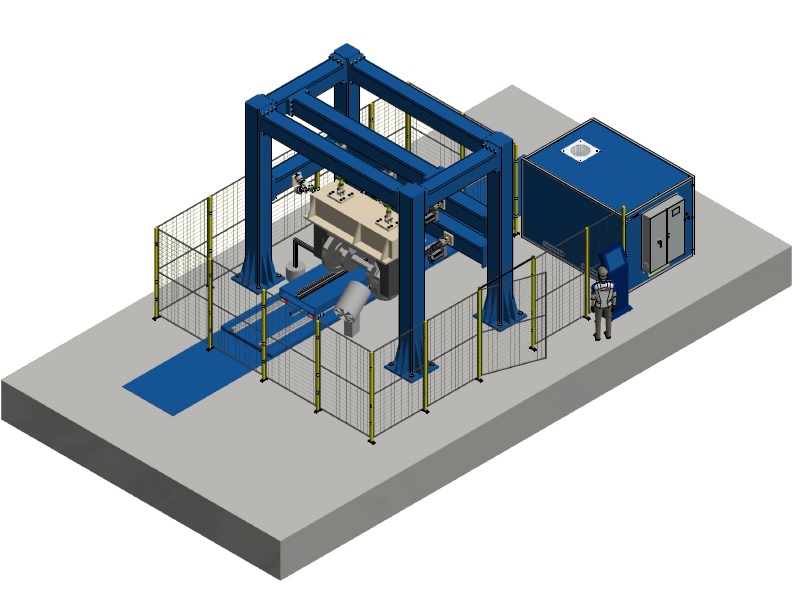

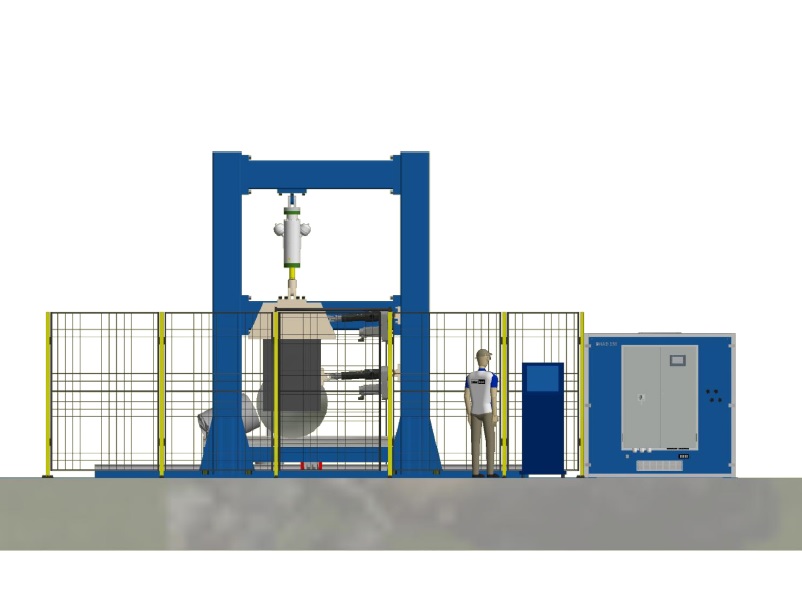

HIGH SPEED RAIL TESTING LABTEST 6.250H.X-2000 – HIGHT SPEED

Basic description:

High speed rail testing in dynamic mode…

A test set consisting of a welding frame and a base support plate formed by precise linear guidance and clamping of the tested sample. This assembly is controlled by REXROTH servo-hydraulic compact test cylinders enabling precise control of the machine in horizontal, vertical and side tilting modes. The system of artificial braking of two-wheelers consists of a special air brake caliper controlled from a central measuring system. A device for blasting water and oil on a rail controlled from a central measuring system….

Basic parameters:

Maximum load in the vertical axis / stroke – 250kN / 100 mm, maximum lateral load on the axle / stroke – 40kN / 100 mm, maximum longitudinal load on the axle / stroke – 40kN / 100 mm, active circumference of the rotary wheel with constant speed – 7500 mm, standard selectable test speed – 6m/s, repeatability of approach to position – ± 0.01 mm, Maximum test frequency 40 Hz, machine dimensions: Height – 4510 mm, Width – 6000 mm, Depth – 5300 mm, machine power consumption (without accessories) – approx. 200 kVA

Application – Standards:

Railway industry – standards ČSN EN 13674-1+A1, AREMA 2019, ГОСТ Р51685; ГОСТ Р 5580

Materials tested:

rails, wheel-rail combination, pair of wheels-2 rails combination

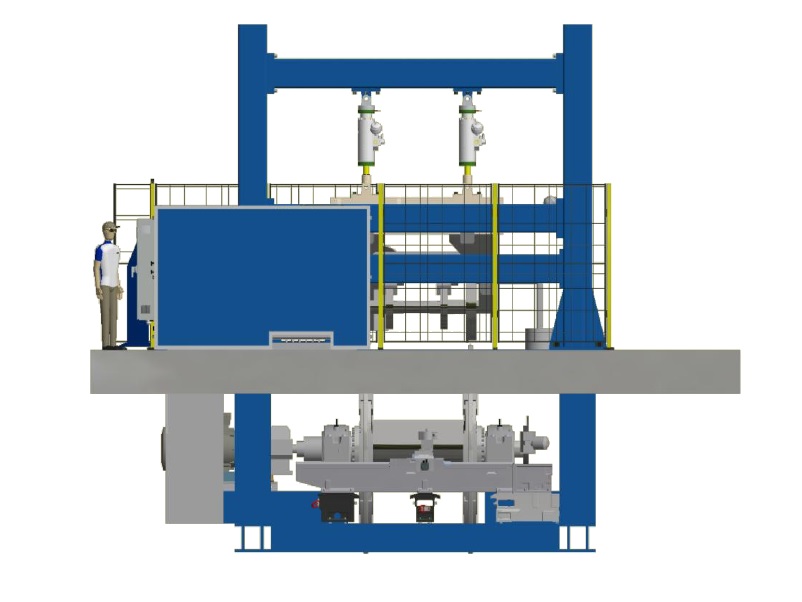

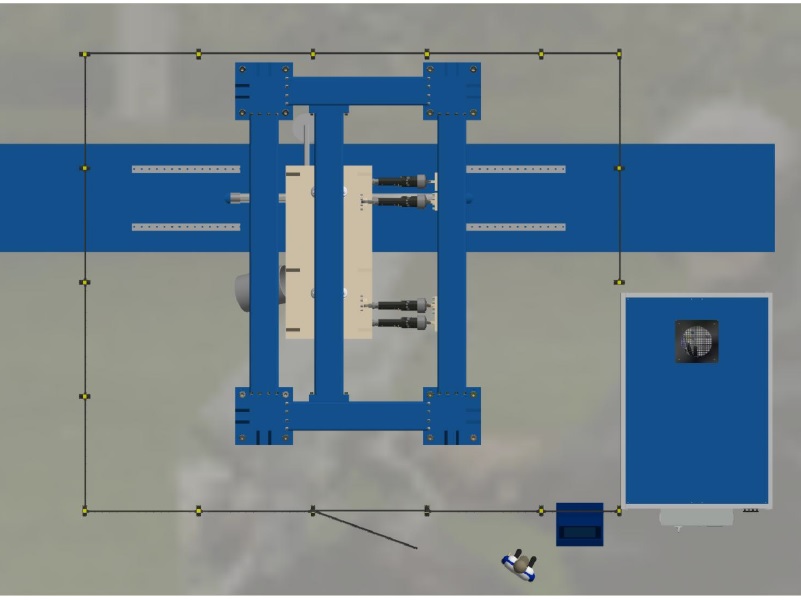

LOW SPEED RAIL TESTING LABTEST 6.250H.X-2000 – LOW SPEED

Basic description:

Low speed rail testing in dynamic mode…

A test set consisting of a welding frame and a base support plate formed by precise linear guidance and clamping of the tested sample. This assembly is controlled by REXROTH servo-hydraulic compact test cylinders enabling precise control of the machine in horizontal, vertical and side tilting modes. The system of artificial braking of two-wheelers consists of a special air brake caliper controlled from a central measuring system. A device for blasting water and oil on a rail controlled from a central measuring system….

Basic parameters:

Maximum load in the vertical axis / stroke – 250kN / 100 mm, maximum lateral load on the axle / stroke – 40kN / 100 mm, maximum longitudinal load on the axle / stroke – 40kN / 100 mm, active length of the support with constant speed – 2000 mm, max length of sliding support – 3000 mm, standard test speed – 2m/s, repeatability of approach to position – ± 0.01 mm, maximum test frequency 30 Hz, machine dimensions: Height – 4510 mm, Width – 6000 mm, Depth – 5300 mm , power input of the machine (without accessories) – approx. 200 kV

Application – Standards:

Railway industry – standards ČSN EN 13674-1+A1, AREMA 2019, ГОСТ Р51685; ГОСТ Р 5580

Materials tested:

rails, wheel-rail combination, pair of wheels-2 rails combination

MEZERA

Contact us:

MEZERA

Contact

LABORTECH s.r.o. , Rolnická 1534/130a, 747 05 Opava, Czech Republic

Research & Development

Reducing energy intensity We increase your productivity Development and implementation

News & Events