TESTING SOFTWARE

Contact

DROPTest software

Intuitive software for measuring the impact strength of materials and the impact force profile that you will love…

DROPTest software is a versatile and highly customizable tool for controlling and analyzing impact tests on LABORTECH drop machines, including models DP.1 and DP.2 (up to 2000 J) and DP.3 (up to 120,000 J). It allows precise adjustment of key test parameters such as drop height, impact energy and impact velocity, ensuring repeatability and consistency of results even in tests with extreme energies.

Thanks to the intuitive user interface, operators can easily control the device and monitor the progress of tests in real time. DROPTest supports a wide range of standards such as EN, ISO, ASTM, GOST and BS, guaranteeing global compatibility and testing quality.

The modularity of the software allows its integration with temperature chambers and high-temperature furnaces, which expands the possibilities of testing at different temperatures. Automated functions such as support stroke, mandrel identification and punch adjustment further increase work efficiency and minimize the risk of errors.

DROPTest is compatible with measurement electronics with a high sampling rate of up to 4 MHz, which allows detailed instrumentation of forces, paths and other critical parameters. Advanced analytical tools include data export in CSV format, visualization of results in graphs and creation of clear reports. The software is designed for seamless cooperation with SIEMENS PLCs and touch LCD displays, which ensures fast and reliable operation. The modular architecture of DROPTest allows adaptation to specific customer needs, including special testing scenarios or combined applications.

Thanks to its robustness and regular updates, DROPTest represents a long-term sustainable solution for testing from low-capacity to high-capacity machines. It is an ideal choice for industrial, scientific and research applications that require high accuracy, reliability and flexibility in impact testing.

Get to know DROPTest software

Advanced software for managing impact tests from low to extreme energies…

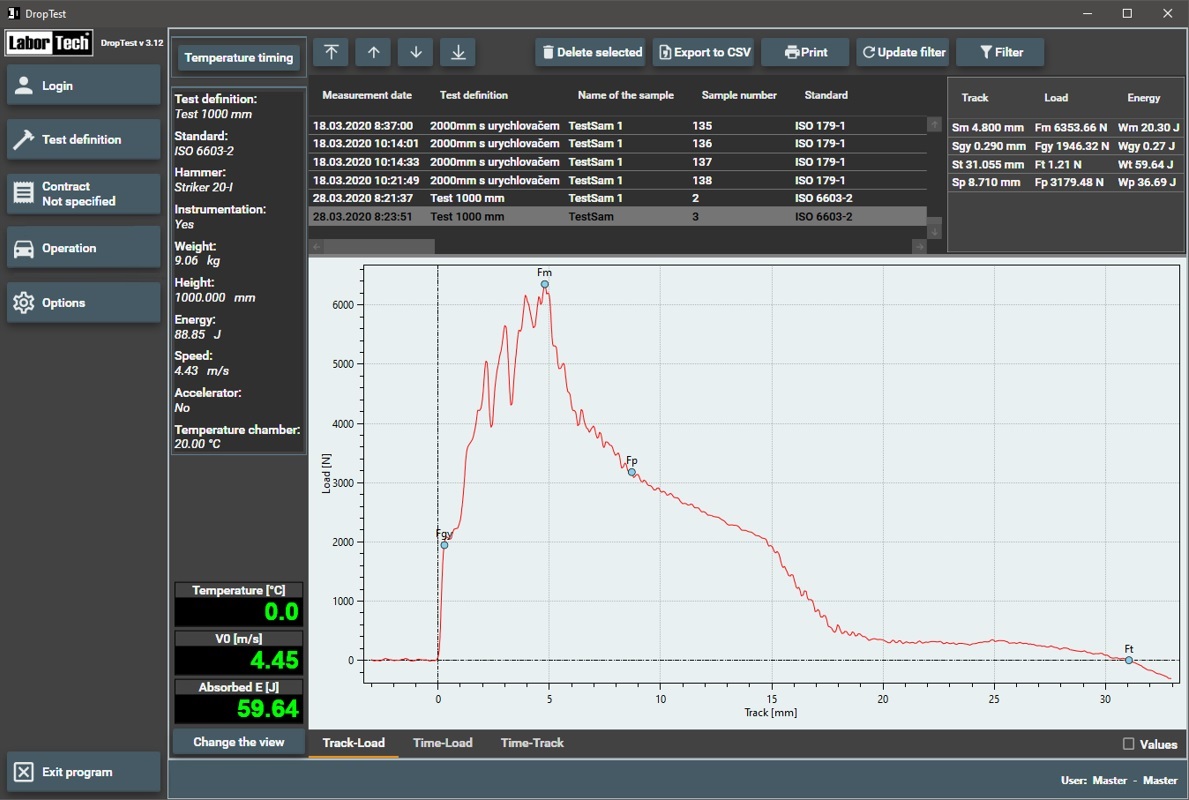

MAIN USER INTERFACE

The main user interface – the basic screen of the DROPTest software is designed to provide users with a clear and intuitive control of key functions via the main bar. This bar contains six control programs that ensure comprehensive management and easy navigation in the software environment: SOFTWARE VERSION, PROGRAM USER LOGIN, TEST PARAMETER DEFINITION, ORDER DEFINITION, MAIN – OPERATING SCREEN, PROGRAM SETTINGS. This structure ensures effective management of all aspects of the testing process and contributes to the user-friendliness of the entire system.

MEZERA

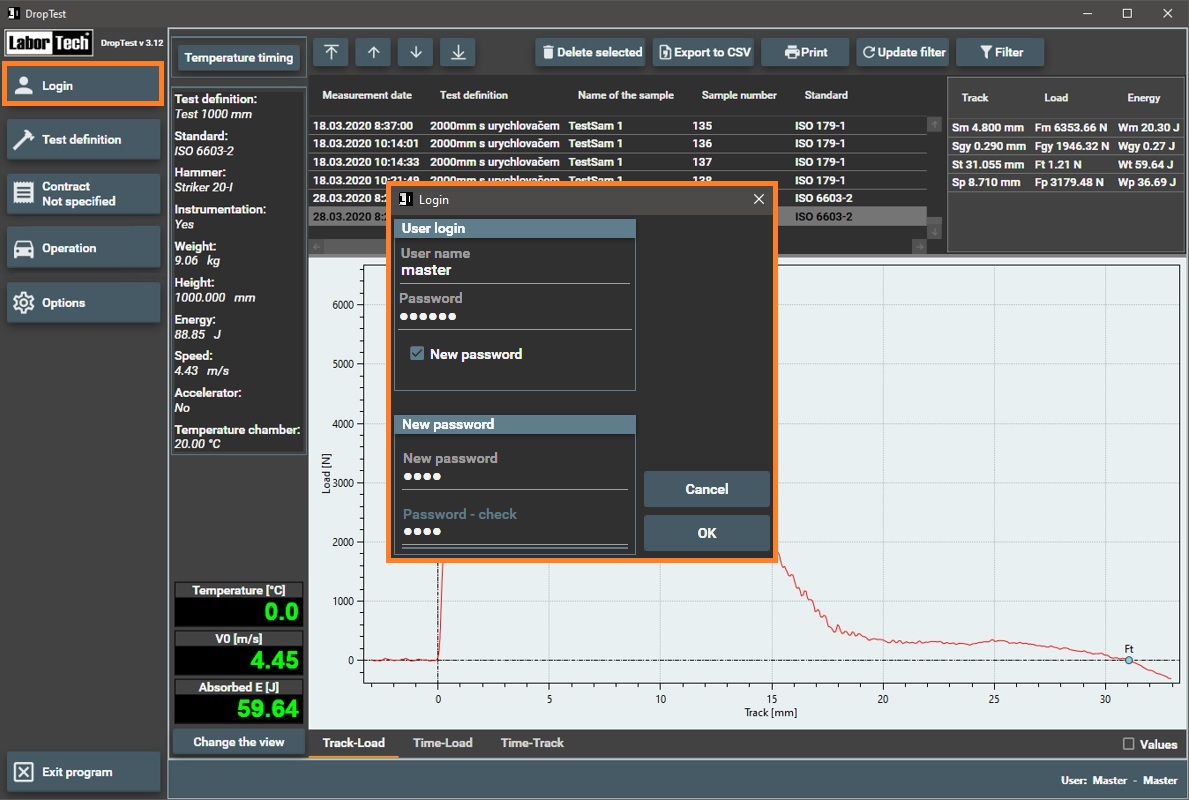

PROGRAM USER LOGIN

After pressing the “Login” button, a dialog box appears where you can enter your username and password. If the user is already logged in, they will be logged out first. Login is confirmed by pressing the “OK” or “Cancel” buttons. Changing the password is done by entering the current password, the new password and confirming it. This process ensures security and correct access to data.

MEZERA

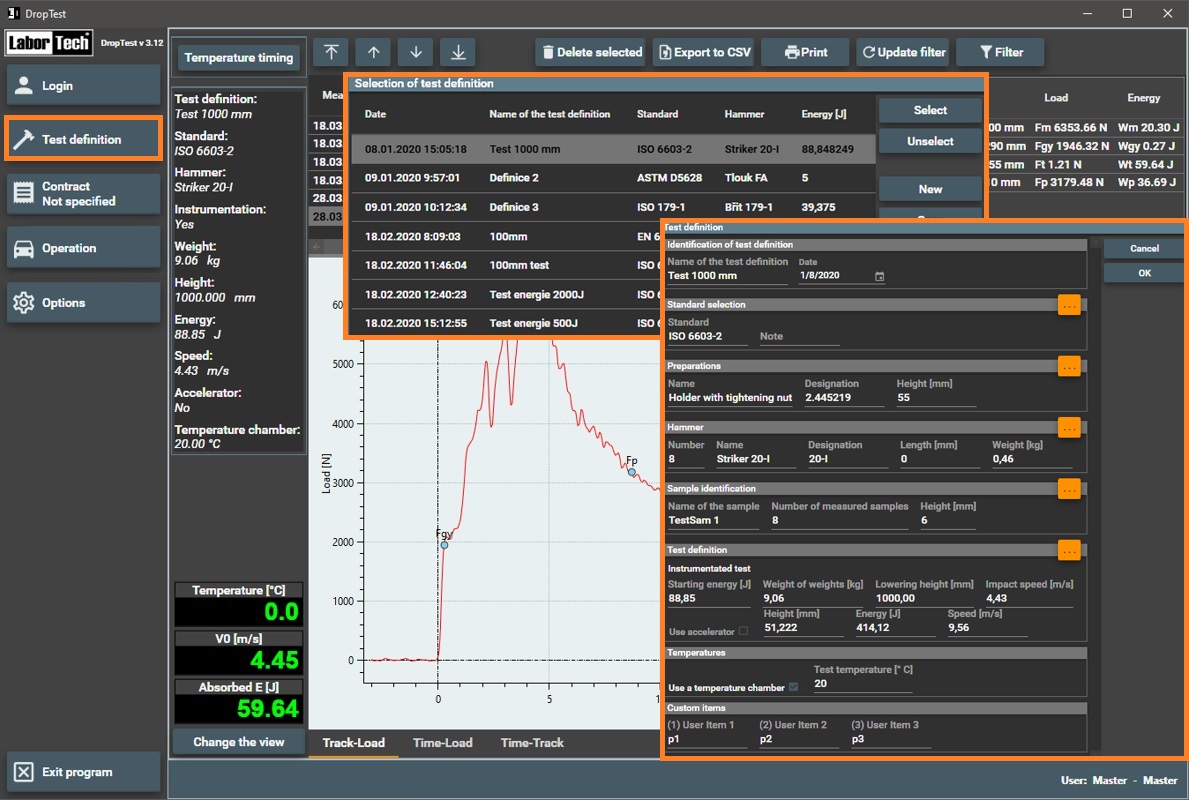

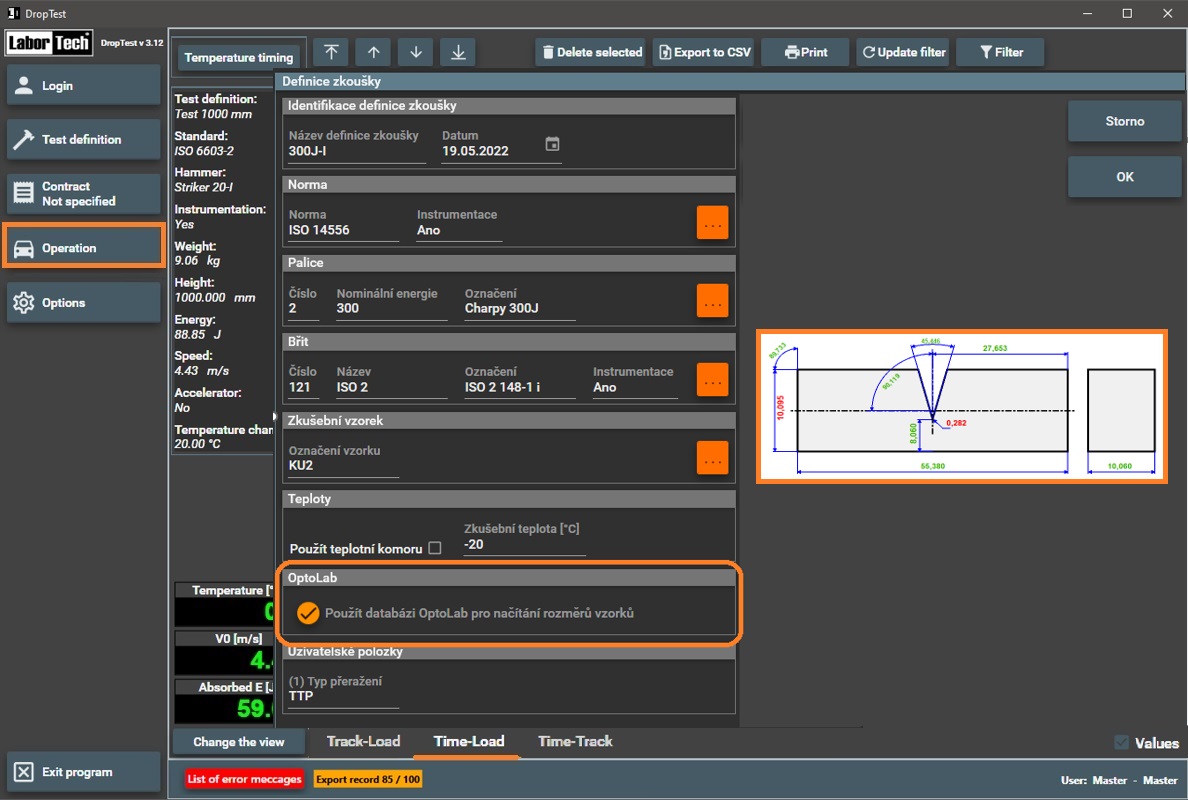

DEFINITION OF TEST PARAMETERS

The user can create new test definitions or edit existing ones. The definition contains the test name, standard, used fixtures and samples. Parameters such as impact energy, drop height or use of an accelerator are set. Width, height and number of pieces can be selected for samples. A simple interface makes it easy to enter values and check them. The user can also select the fixture for holding the sample and the corresponding edge according to the defined standard. If changes are not allowed in the sample list, the sample can only be selected. By activating the “Allow changes” option, buttons for entering, editing or deleting samples are displayed.

MEZERA

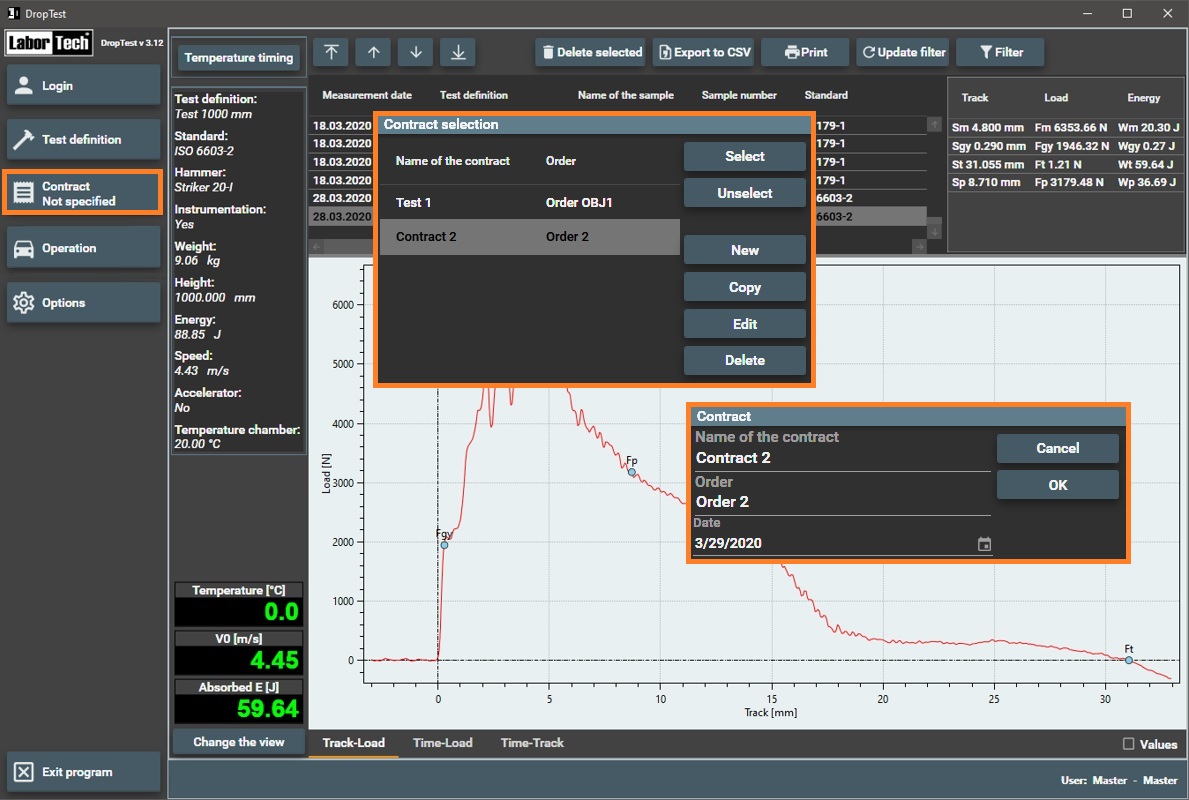

ENTERING THE ORDER DEFINITION

The order contains the name, order number and creation date. After entering this information, the order can be saved, edited, copied or deleted. Order management is intuitive and similar to the exam definition. All orders are displayed in a clear list. This section ensures smooth administrative processes for organizing exams.

MEZERA

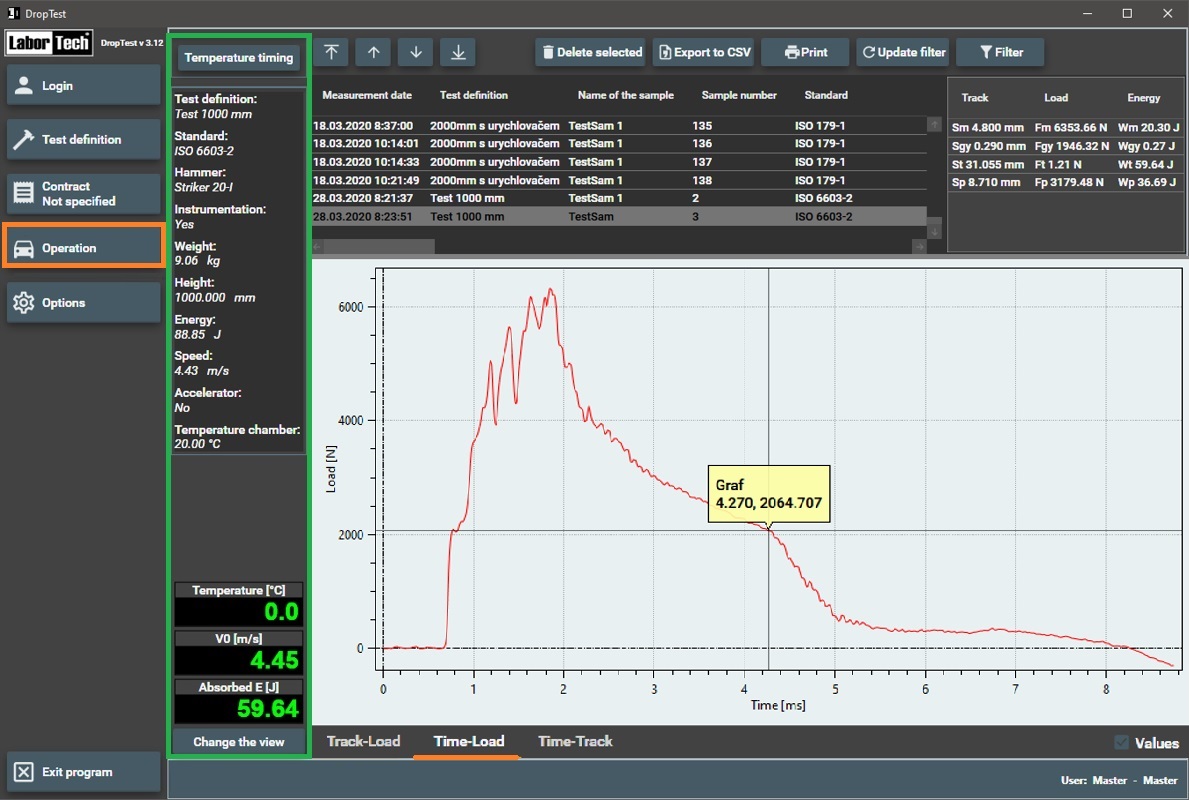

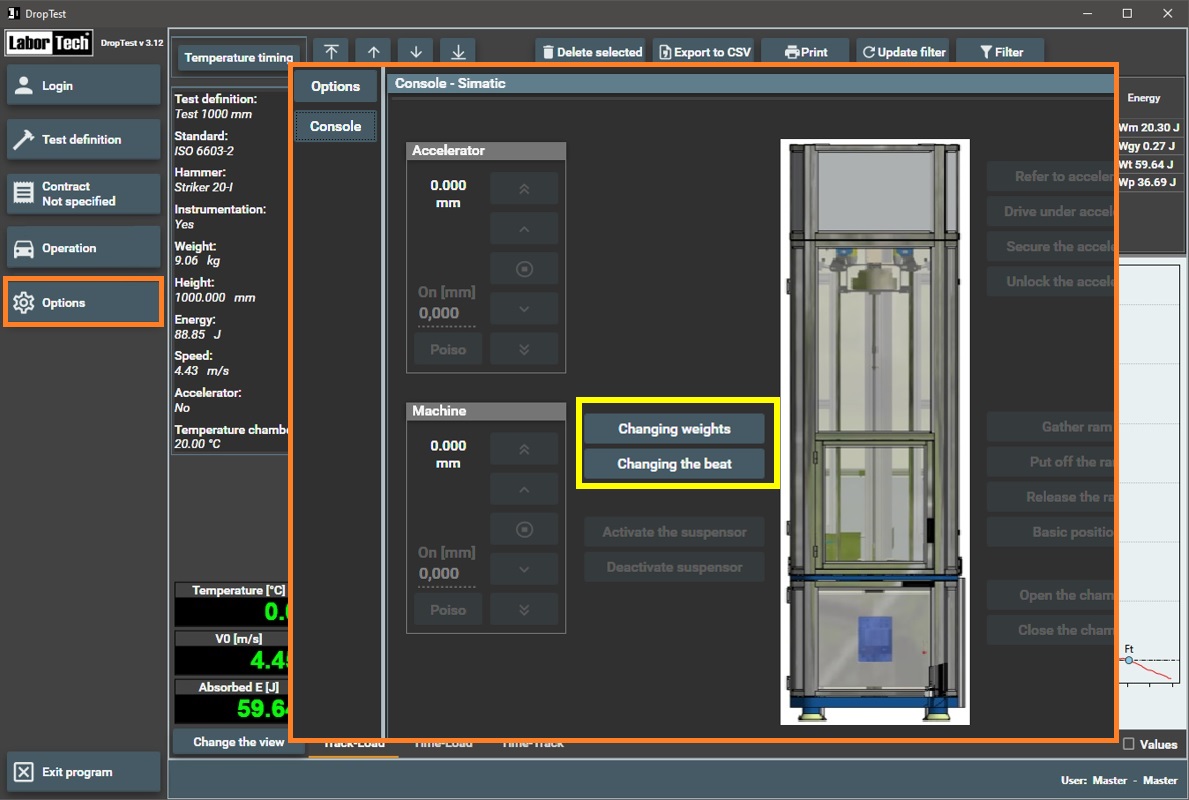

MAIN – OPERATION SCREEN

The operating screen is divided into an information panel, a measurement panel and a graphic panel. The information panel displays the current test status, including parameters such as speed and absorbed energy. The measurement panel allows for data manipulation, while the graph displays the instrumentation progress. The user can easily monitor and analyze the results in real time.

MEZERA

MAIN – OPERATING SCREEN – INFORMATION PANEL

The information panel displays key data from the active test definition, such as standard, speed, energy and height setting. The values displayed include: Notch toughness [J/cm²], which determines the material’s resistance to impact, Absorbed energy [J], measured during the test, Other parameters, such as initial height or sample temperature, can be displayed according to the settings. The “Change display” button allows you to switch between two modes: full-screen display of measured values or a combination of values and an analog graph, if instrumentation is available for instrumented testing according to EN ISO 14556 and ASTM E2298.

MEZERA

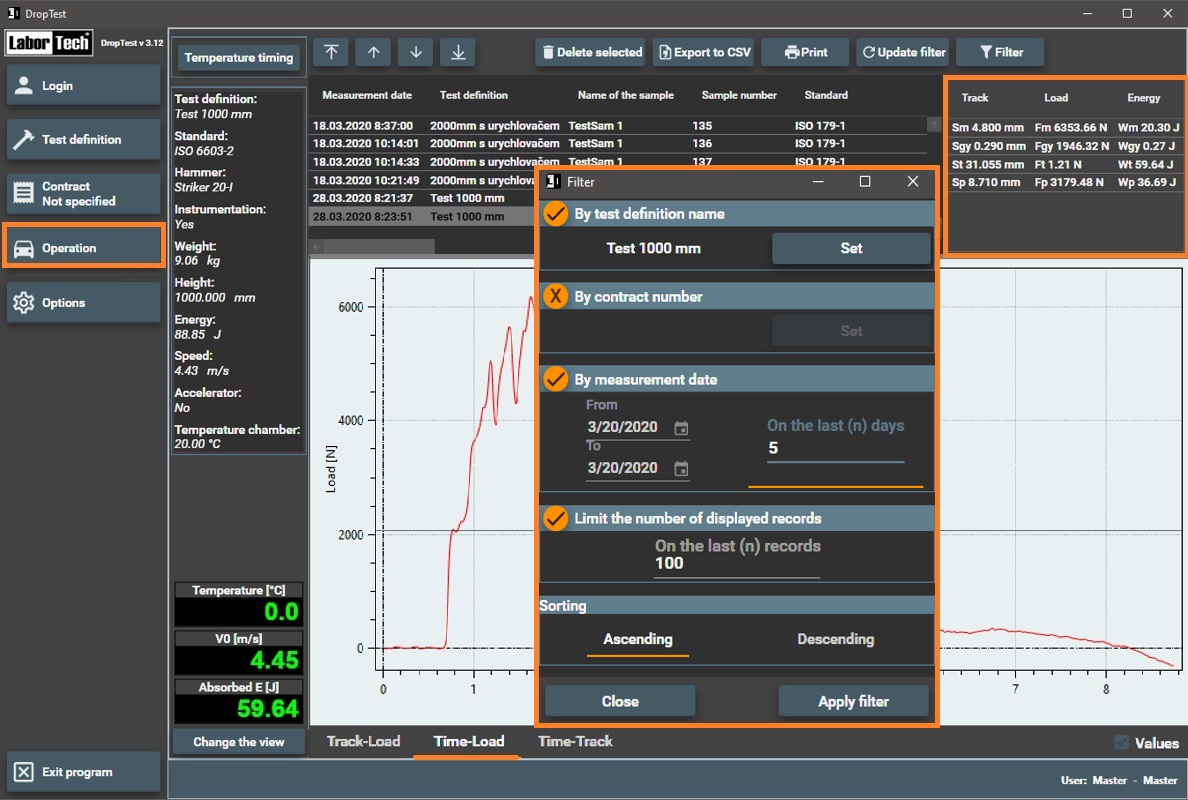

MAIN – OPERATION SCREEN – WORKING WITH DATA

The measured values panel allows data to be exported to CSV format. The exported data contains names, units and values of all measured parameters. Filters can be used to select specific data according to the definition of the test, order or measurement date. Print buttons allow for the preparation of a report. The panel also allows for quick data review using navigation buttons that simplify switching between individual records or deleting them if necessary. This module supports efficient management and sharing of results.

MEZERA

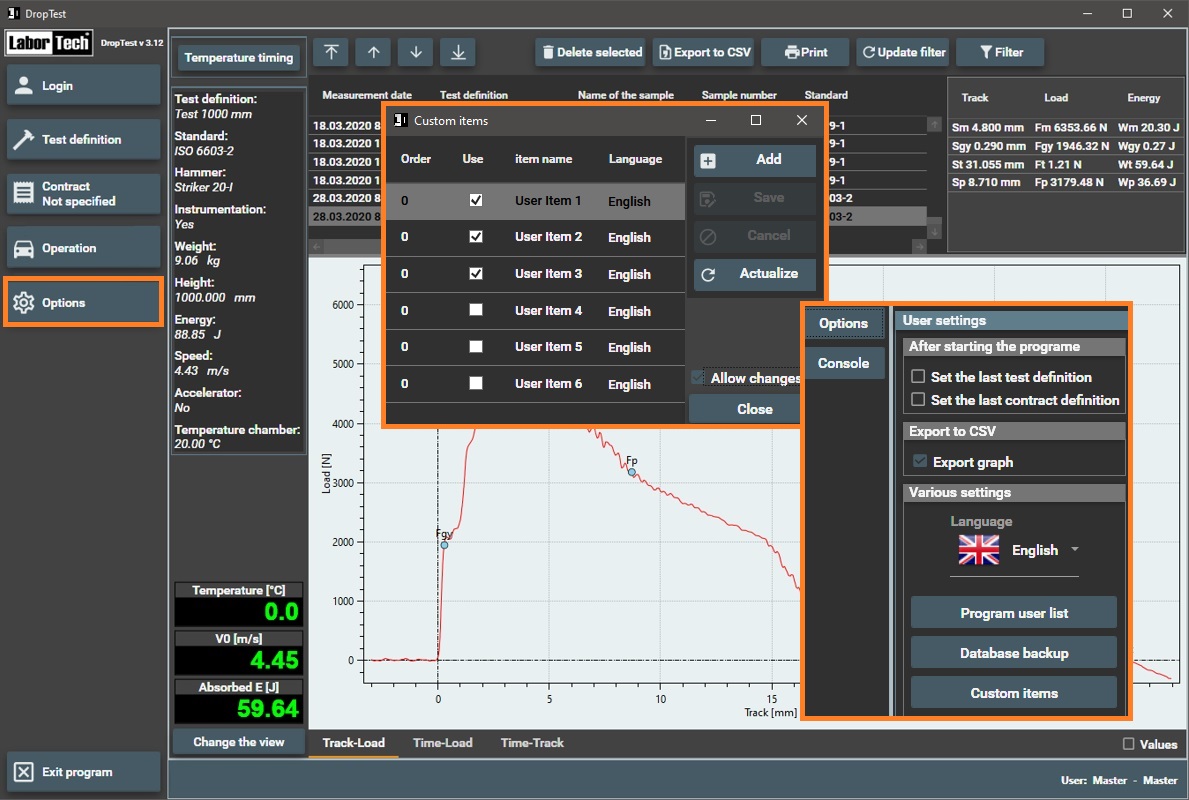

The program settings offer the ability to set the language, user items and preferences for data export. Automatic selection of the last used test or job definition is available in the settings. The database backup includes all values, graphs and user profiles. Users with advanced permissions can set machine parameters. The menu includes the option to enable the export of graphs and other data, which is suitable for detailed analysis of results. The user interface can be fully personalized, including defining specific parameters or saving preferences for each project.

MEZERA

–

Do you have any questions about our software?

Please feel free to contact our application engineers.

We look forward to hearing from you.

–

MEZERA

DROPTest SOFTWARE EXPANSION MODULES – BASIS

Basic software that can be easily expanded with additional modules…

DROPTest MODULE – I – INSTRUMENTATION

Depending on the type of instrumentation selected (force-time or force-distance), test results can be automatically recorded, including reverse modification and evaluation according to EN ISO 14556:2015. Recording of multiple curves, zooming using ZOOM – determining x, y coordinates for individual samples, etc. Linearization of the instrumented cutting edge course including calibration according to EN ISO 148-2, ASTM E 23 and ASTM E 2298 Basic technical data: Sampling frequency – 4 MHz, A/D converter -16 bit, path resolution up to 0.05 mm

MEZERA

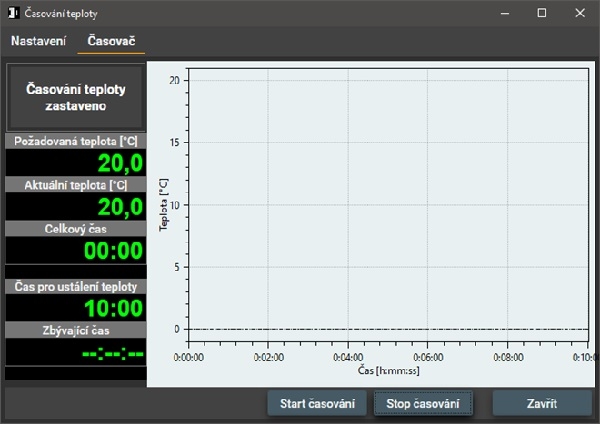

DROPTest MODULE – T – TEMPERATURE MONITORING

Automatic temperature monitoring and mutual communication with the LABCool 21 cooling chamber. Setting parameters – coolant temperature tolerance, temperature stabilization time setting, temperature stabilization time setting after a drop outside the tolerance, X and Y axis unit settings in the graph, tolerance field, etc. After the timing is completed, the information message will change to green and the “Start test” button on the machine panel will be unlocked. Display – desired temperature, current temperature, total time, temperature stabilization time, remaining time, graphical display of the progress, etc.

MEZERA

DROPTest MODULE – BR – ROBOT- X-RUNNER

The BR software module is designed for the BLUE RUNNER and YELOW RUNNER robotic systems from LABORTECH. These systems were created primarily to minimize the influence of the operator on the reproducibility of test results by loading and breaking samples. Automatic selection of samples from a defined container. Communication and control with a temperature chamber for temperatures up to -95 °C, including the container system. Communication with the optical inspection of samples OPTOLab 55 II, including database exchange of measured data.

MEZERA

DROPTest MODULE – O – SAMPLE DIMENSIONS

Data acquisition module from the OPTOLab 55 II optical system. Display of measured values with given tolerances directly on the sample. Saving all values in the database with filtering of individual parameters. Data transfer to the system: height, length, width of the sample, axis distance, height under the groove, groove angle, axis angle, root radius, and side angle

We will be happy to advise you on the right choice of machine…

Contact

LABORTECH s.r.o. , Rolnická 1534/130a, 747 05 Opava, Czech Republic

Research & Development

Reducing energy intensity We increase your productivity Development and implementation

News & Events