TESTING SOFTWARE

Contact

IMPACTTest software

Measuring the impact strength of materials and the impact force profile you’ll love…

IMPACTTest – BASIC is an intelligent, intuitive and powerful software that is an integral part of all LabTest CHK series impact pendulum hammers from LABORTECH. Designed for impact tests according to a wide range of international standards, including ČSN EN ISO 148-1, ISO 148-2, ASTM E23 and others, it offers an unlimited number of test methods, a modular library system and a clear visualization of supports, edges and mallets.

The software allows digital and analog display of values, storage of measured data with advanced filtering, statistical evaluation of data and graphs, or printing of reports in PDF format. It also includes a calibration mode according to EN ISO 148-2, automatic cooling timing and data transfer from additional devices such as a thermometer or optical inspection. Extensive customization options include editing samples, standards and item names according to user needs. Setting user rights and operator login ensures security and control over data. Multilingual interfaces (ČJ, EN, DE, FR, POL, RU, ESP, etc.) allow for convenient use worldwide. IMPACTTest supports data export to CSV, MY SQL and MS SQL for further analysis. An unlimited license and easy installation on any computer without the need for license keys make the software an ideal solution for all laboratories.

Thanks to its performance and flexibility, IMPACTTest is an essential tool for accurate and efficient impact testing, which significantly simplifies work, increases productivity and provides maximum reliability in everyday operation.

Get to know IMPACTTest software

“With us, what is above standard elsewhere is standard.”…

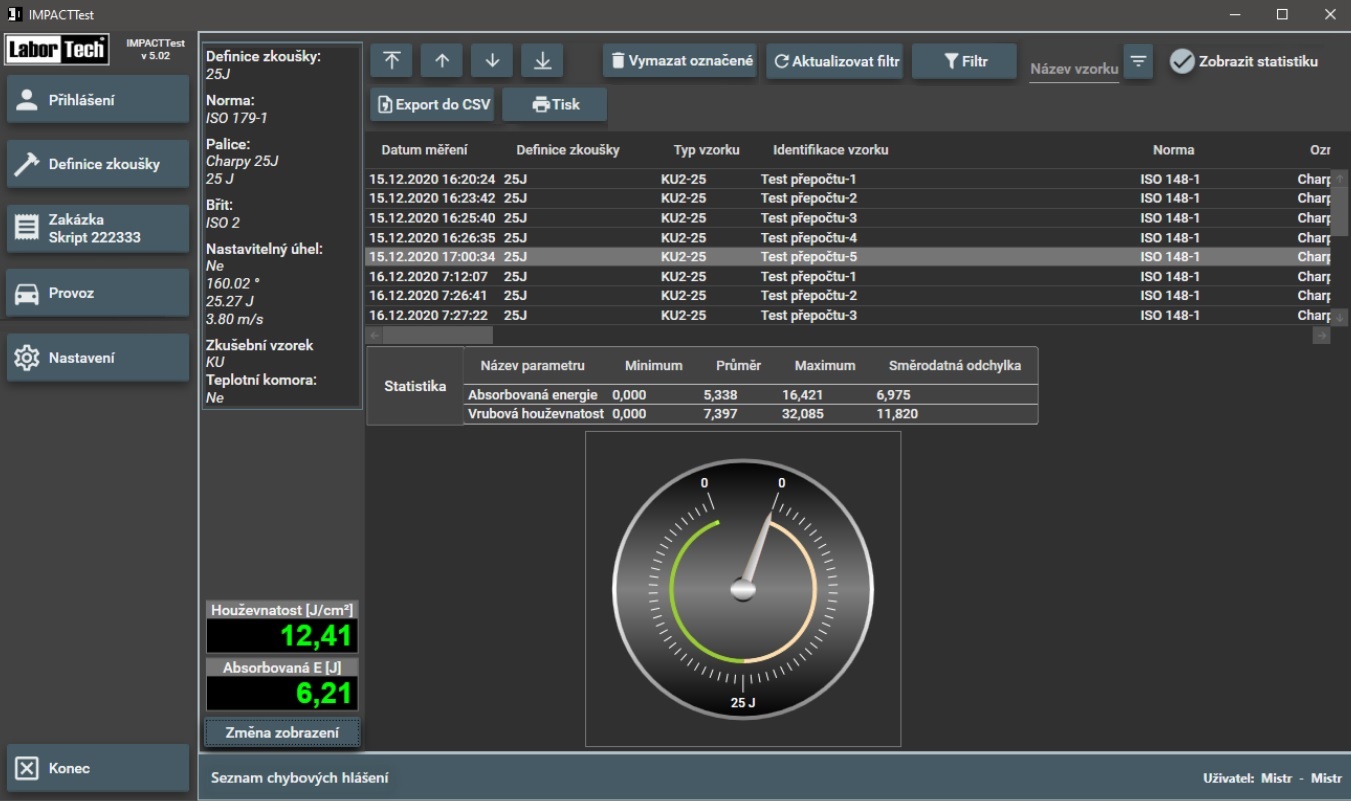

MAIN USER INTERFACE

The main user interface – the basic screen of the IMPACTTest software is designed to provide users with a clear and intuitive control of key functions through the main bar. This bar contains six control programs that ensure comprehensive management and easy navigation in the software environment: SOFTWARE VERSION, PROGRAM USER LOGIN, TEST PARAMETER DEFINITION, ORDER DEFINITION, MAIN – OPERATING SCREEN, PROGRAM SETTINGS. This structure ensures effective control of all aspects of the testing process and contributes to the user-friendliness of the entire system.

MEZERA

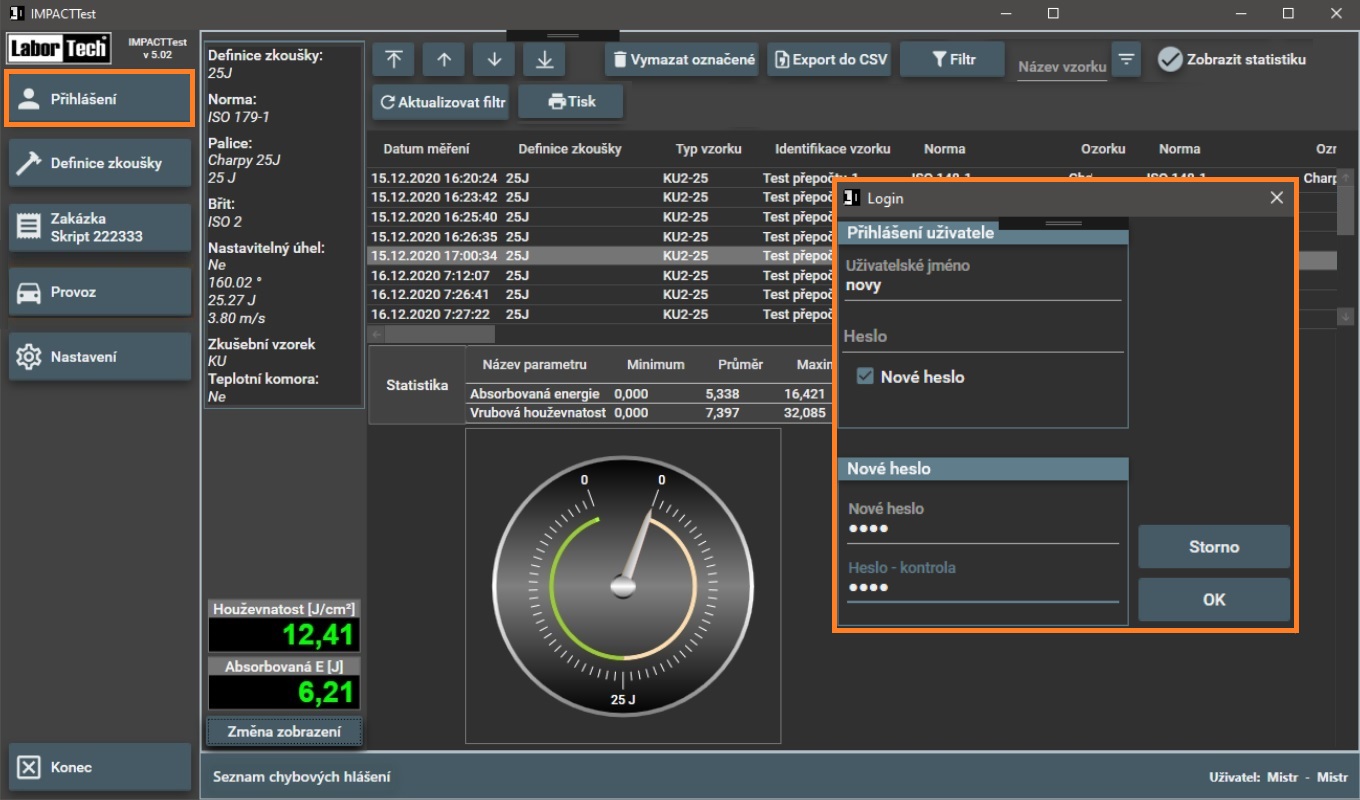

PROGRAM USER LOGIN

Logging in is done via a dialog box where you enter your username and password. Clicking the “OK” button will log you in, while the “CANCEL” button will close the dialog box without changes. If someone is already logged in, a prompt will first appear asking them to log out. To change the password, enter the current password, the new password, and its verification. After confirming with the “OK” button, the password will change and the user will log in with the new password. If the password is entered incorrectly, the system will display a warning message and allow you to try logging in again. Only authorized administrators can manage passwords and users.

MEZERA

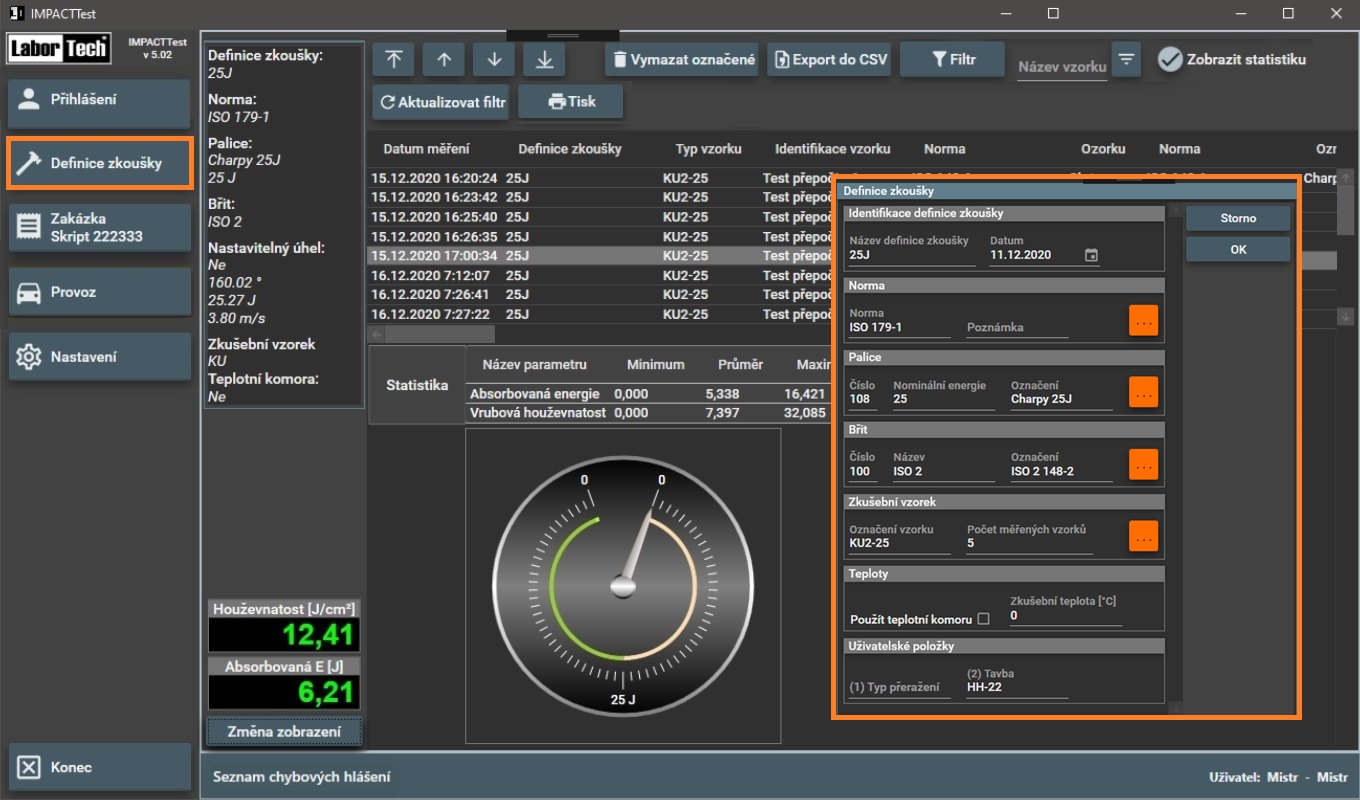

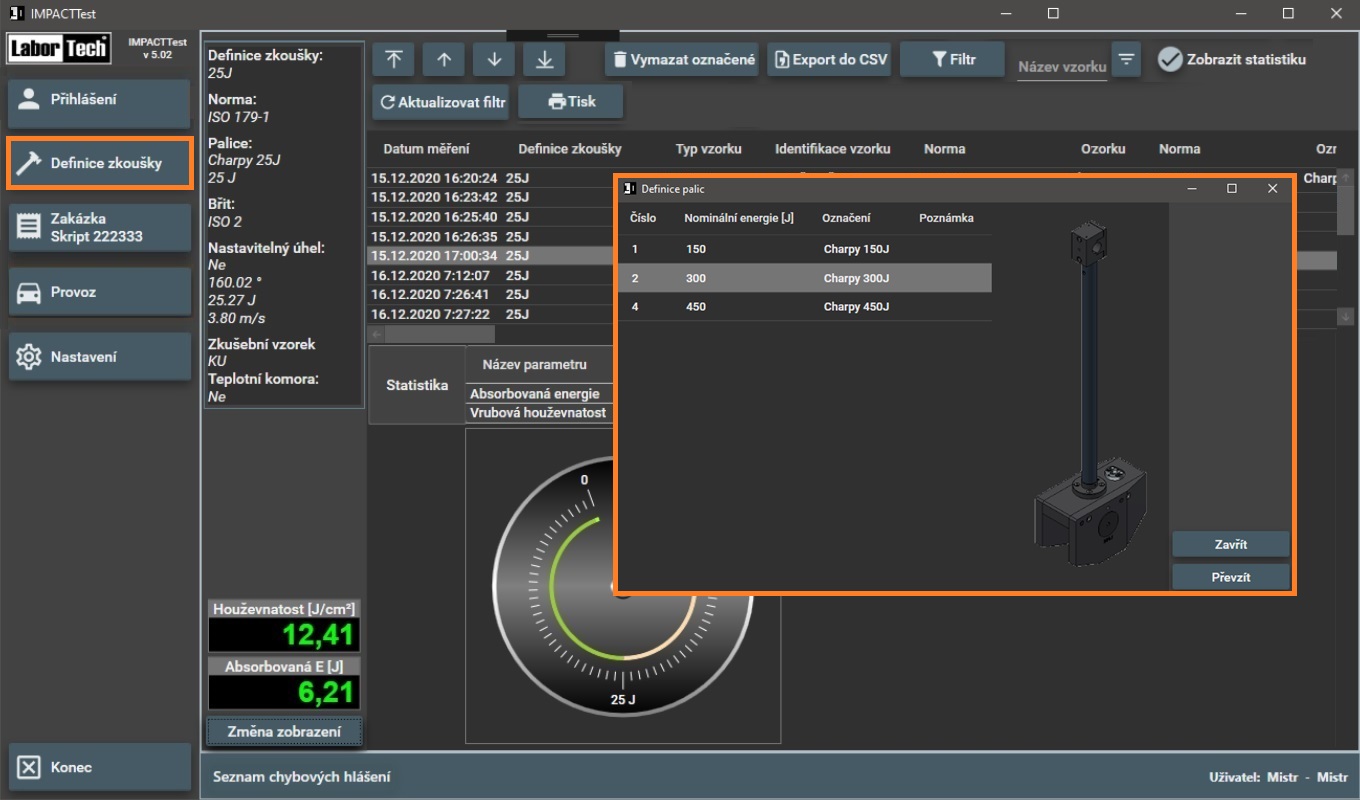

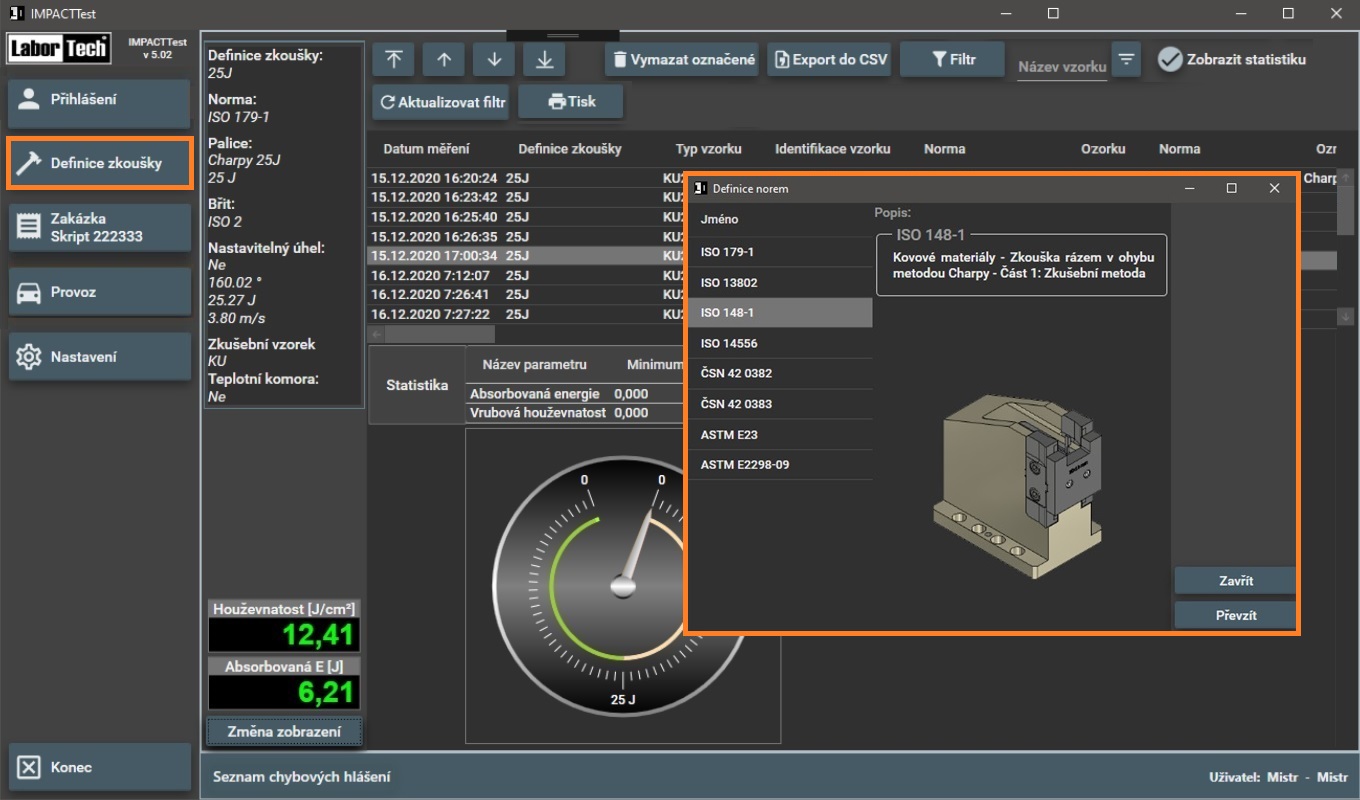

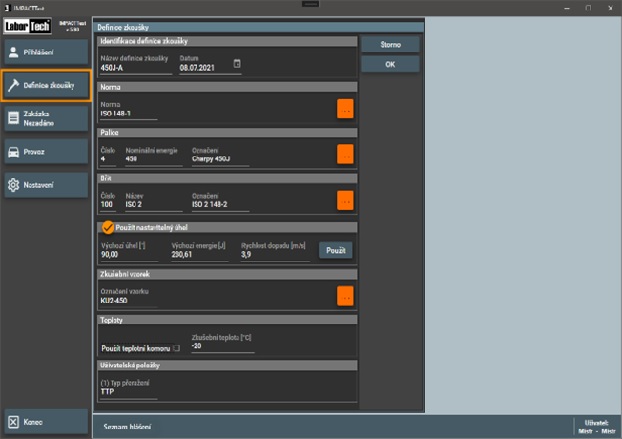

DEFINITION OF TEST PARAMETERS

By pressing the “Test Definition” button, a list of available tests is displayed. The user can select a test with the “Select” button or cancel the selection with “Cancel Selection”. After selection, the set parameters are displayed on the main operating screen. Each test contains identification data such as the test name and creation date. The selection of the required standard is done by pressing the button, which opens the list of available standards. The user can also select the specimen holder and the corresponding cutting edge according to the defined standard. If changes are not allowed in the sample list, the sample can only be selected. By activating the “Allow Changes” option, buttons for entering, editing or deleting samples are displayed.

MEZERA

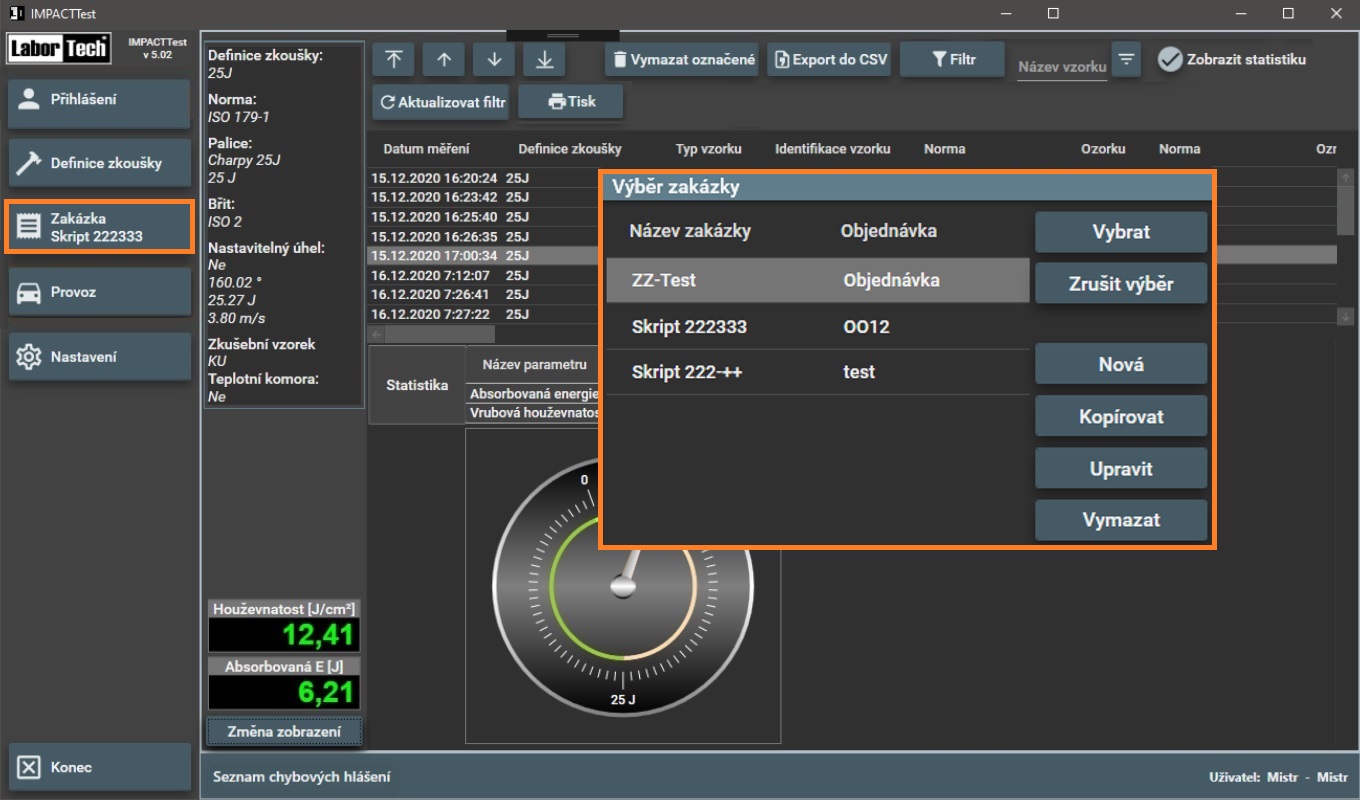

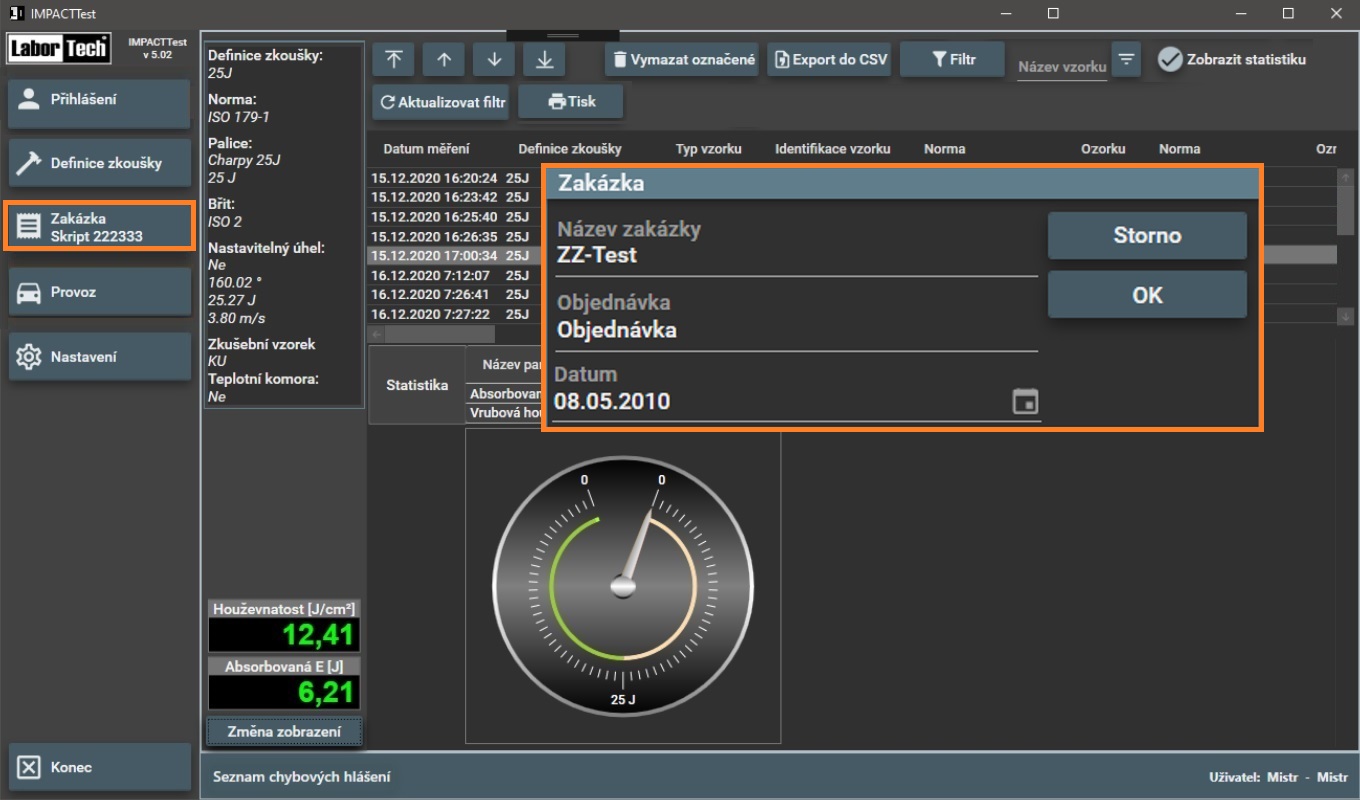

ENTERING THE ORDER DEFINITION

By pressing the “Order Definition” button, a list of existing orders is displayed. The user can select an order, deselect it, create a new one, copy, edit or delete the selected order. The order contains basic information such as the name, order and creation date. After filling in the data, the changes can be confirmed with the “OK” button or canceled with “Cancel”. The control is similar to the “Test Definition” and ensures fast and intuitive work. This module allows for efficient order management for everyday use.

MEZERA

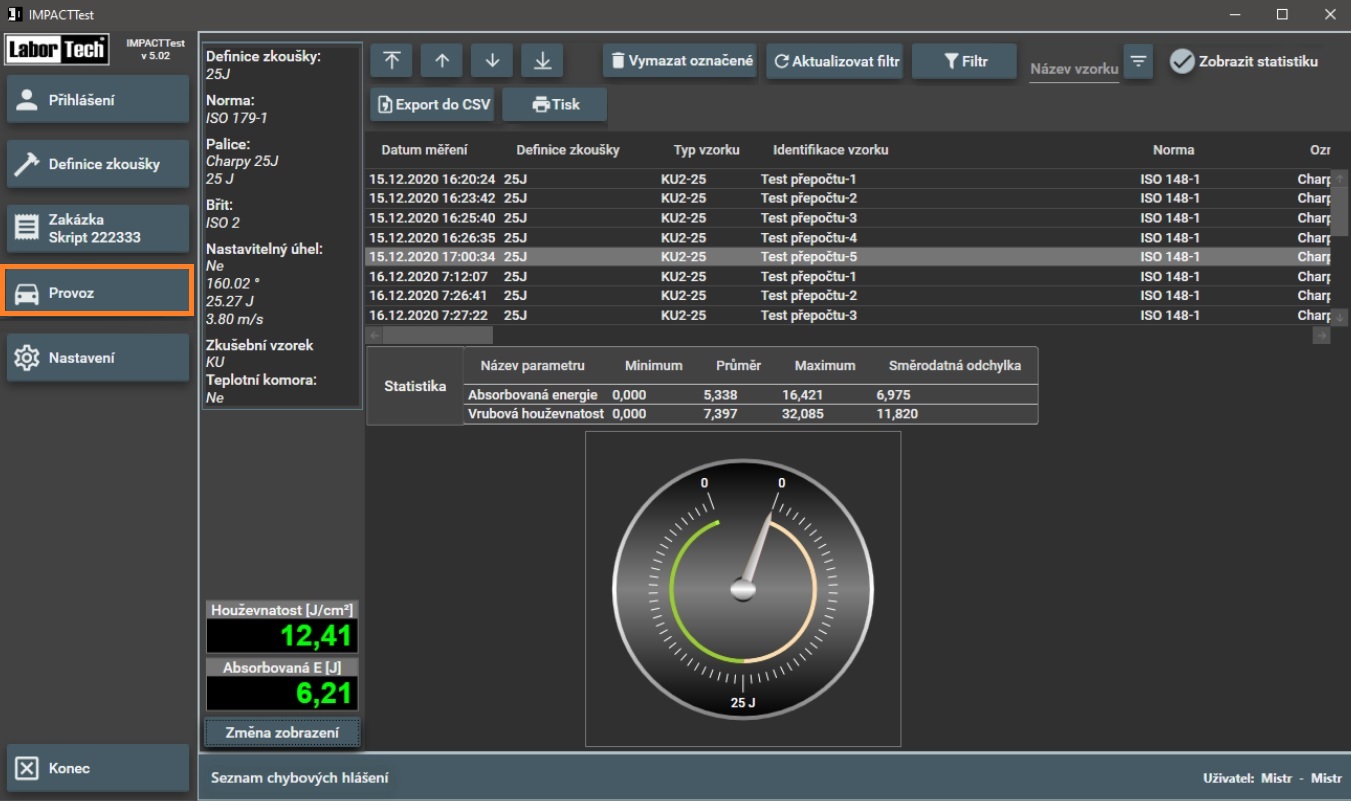

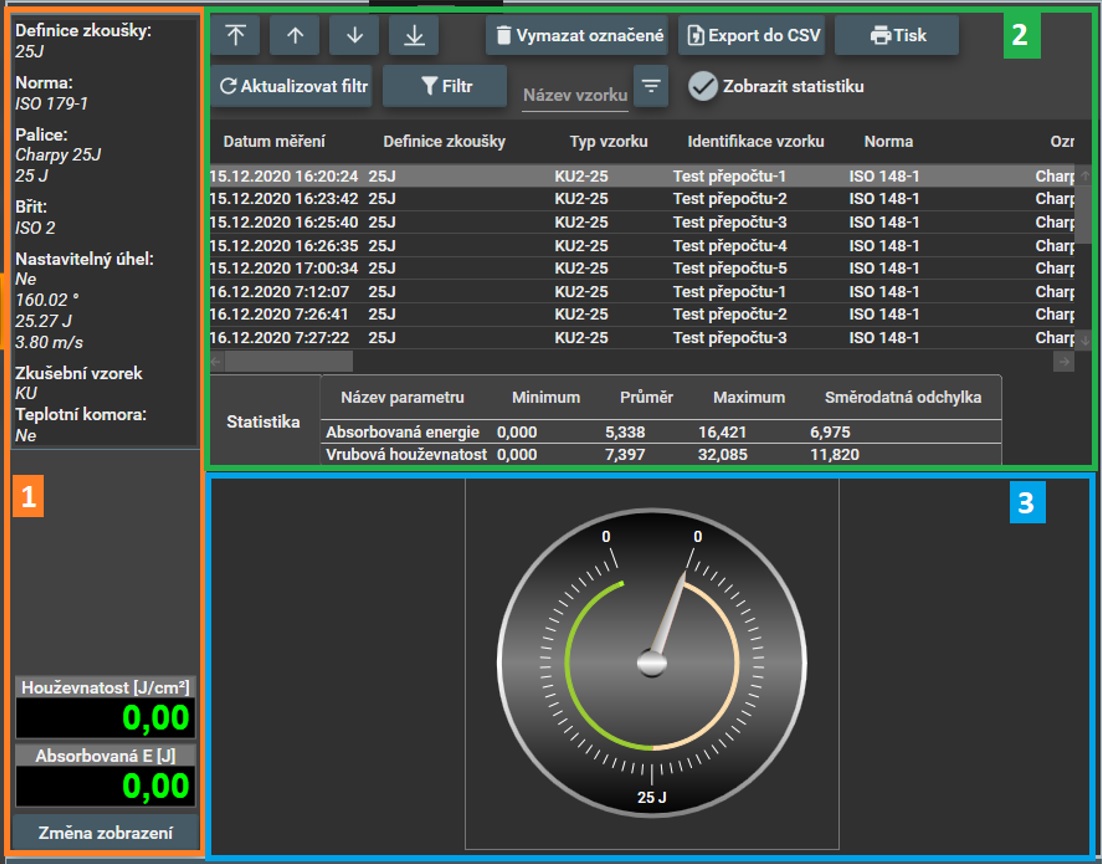

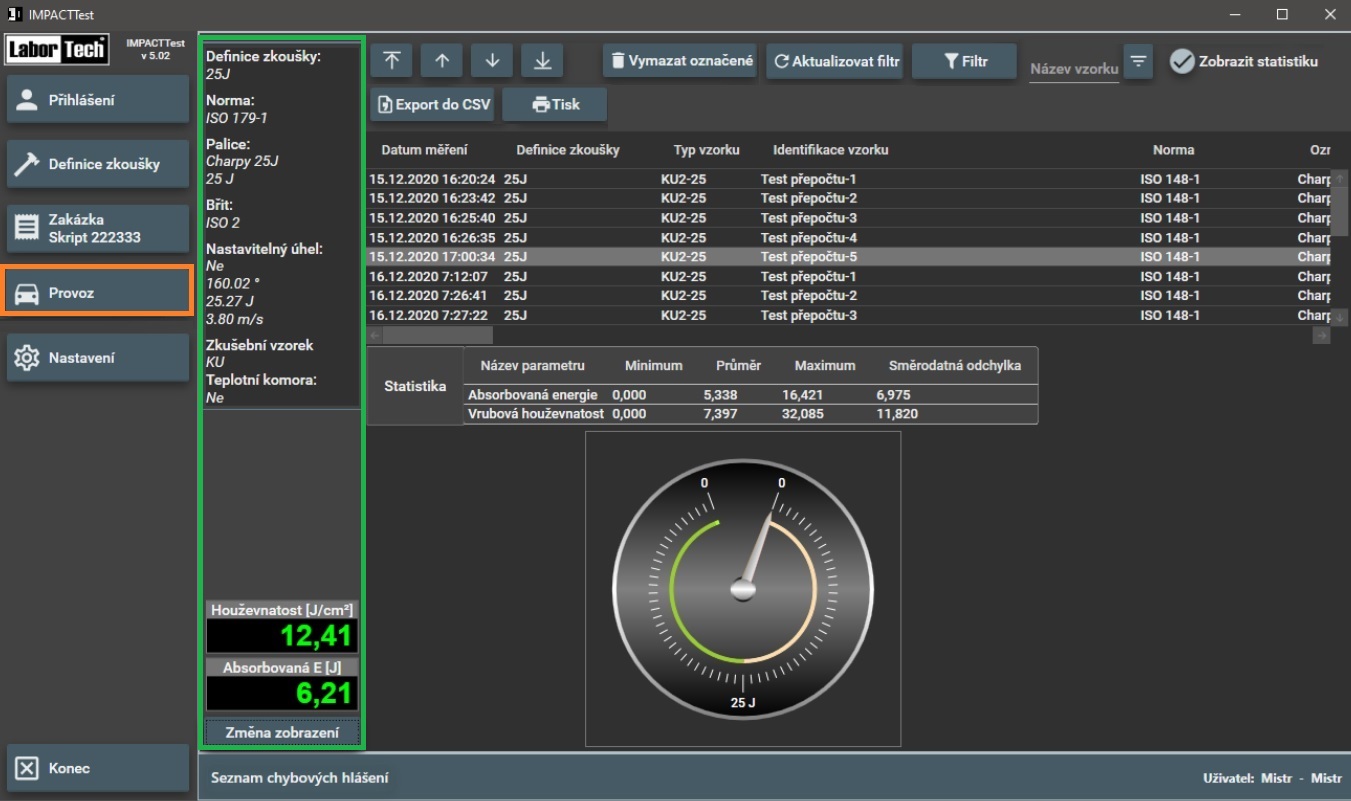

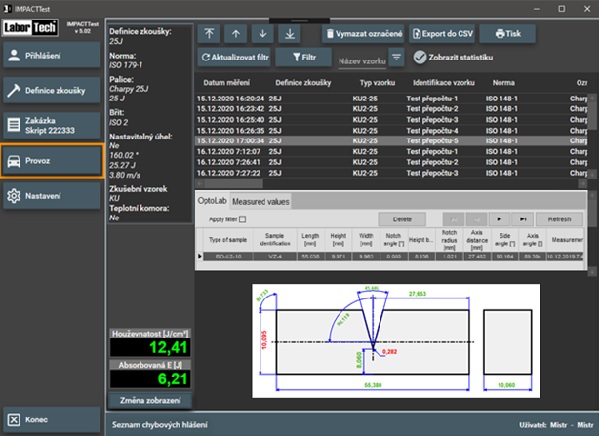

MAIN – OPERATION SCREEN

The program’s operating screen serves as the main working area, which is displayed after pressing the appropriate button. It is divided into three clearly arranged parts: Information panel – provides basic data on the test progress, Measured values panel – displays current test results, Analog meter (Graph) – visualizes measured values in real time. This screen allows a quick overview of all important parameters during device operation.

MEZERA

MAIN – OPERATING SCREEN – INFORMATION PANEL

The information panel displays key data from the active test definition, such as the standard, the used mallet, the cutting edge and the angle setting. The values displayed include: Notch toughness [J/cm²], which determines the material’s resistance to impact, Absorbed energy [J], measured during the test, Other parameters, such as the starting angle or the sample temperature, can be displayed according to the settings. The “Change display” button allows you to switch between two modes: displaying the measured values over the full screen or a combination of values and an analog graph, if instrumentation is available for instrumented testing according to EN ISO 14556 and ASTM E2298.

MEZERA

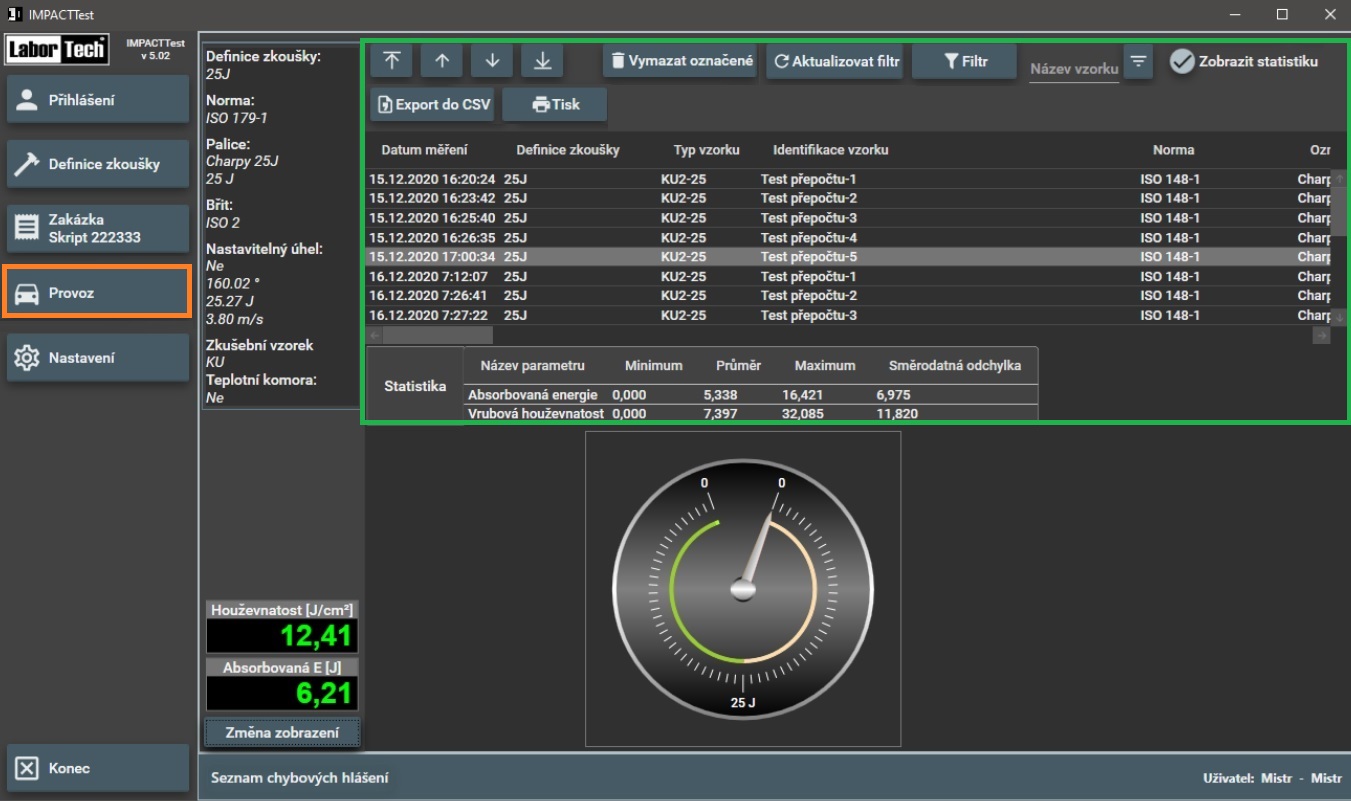

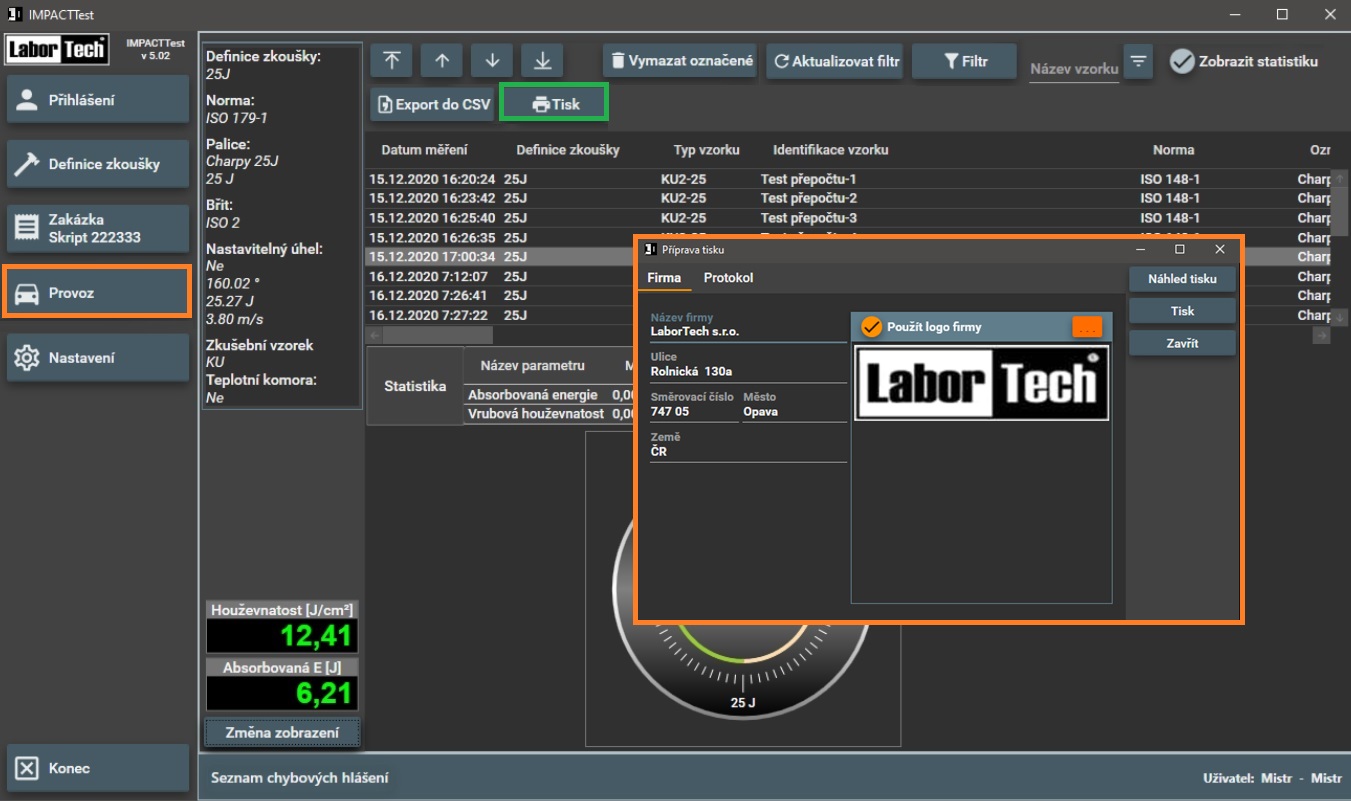

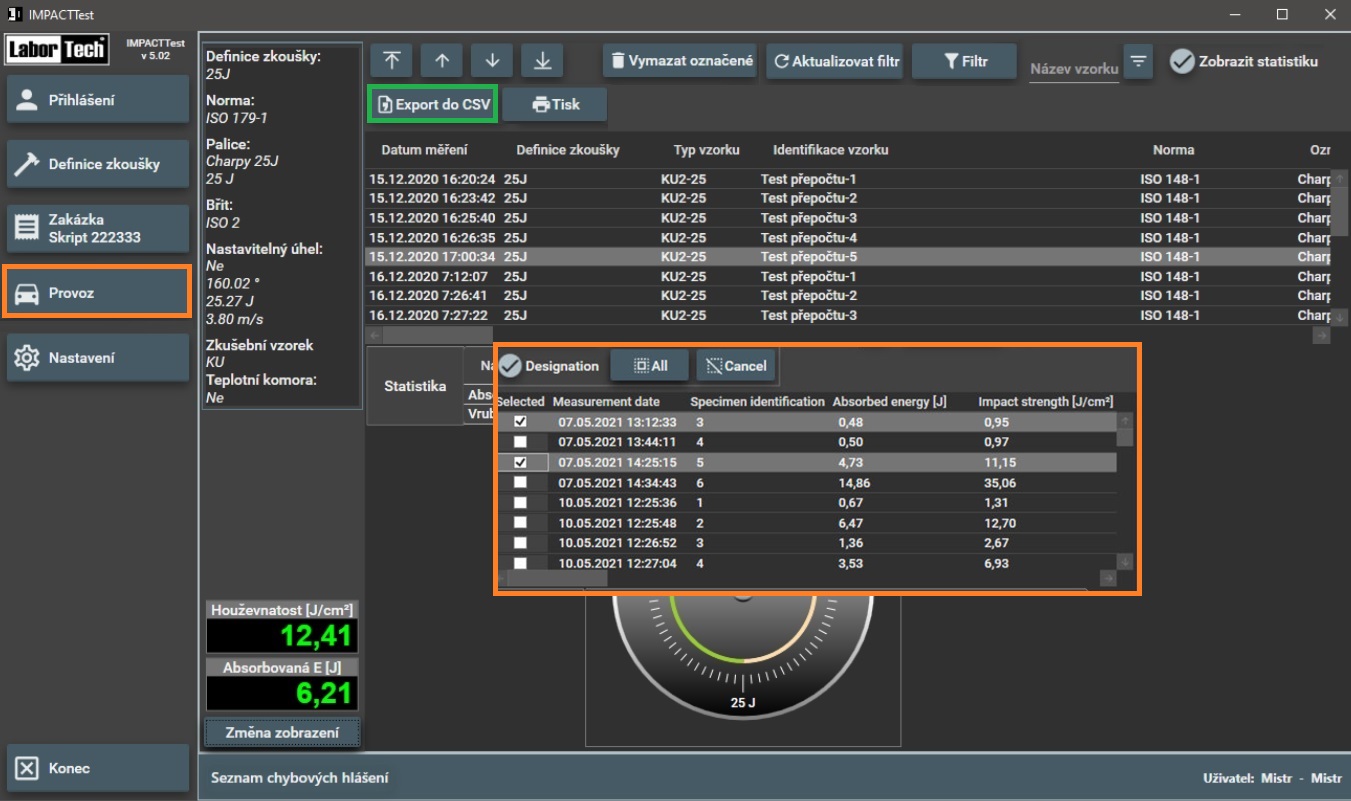

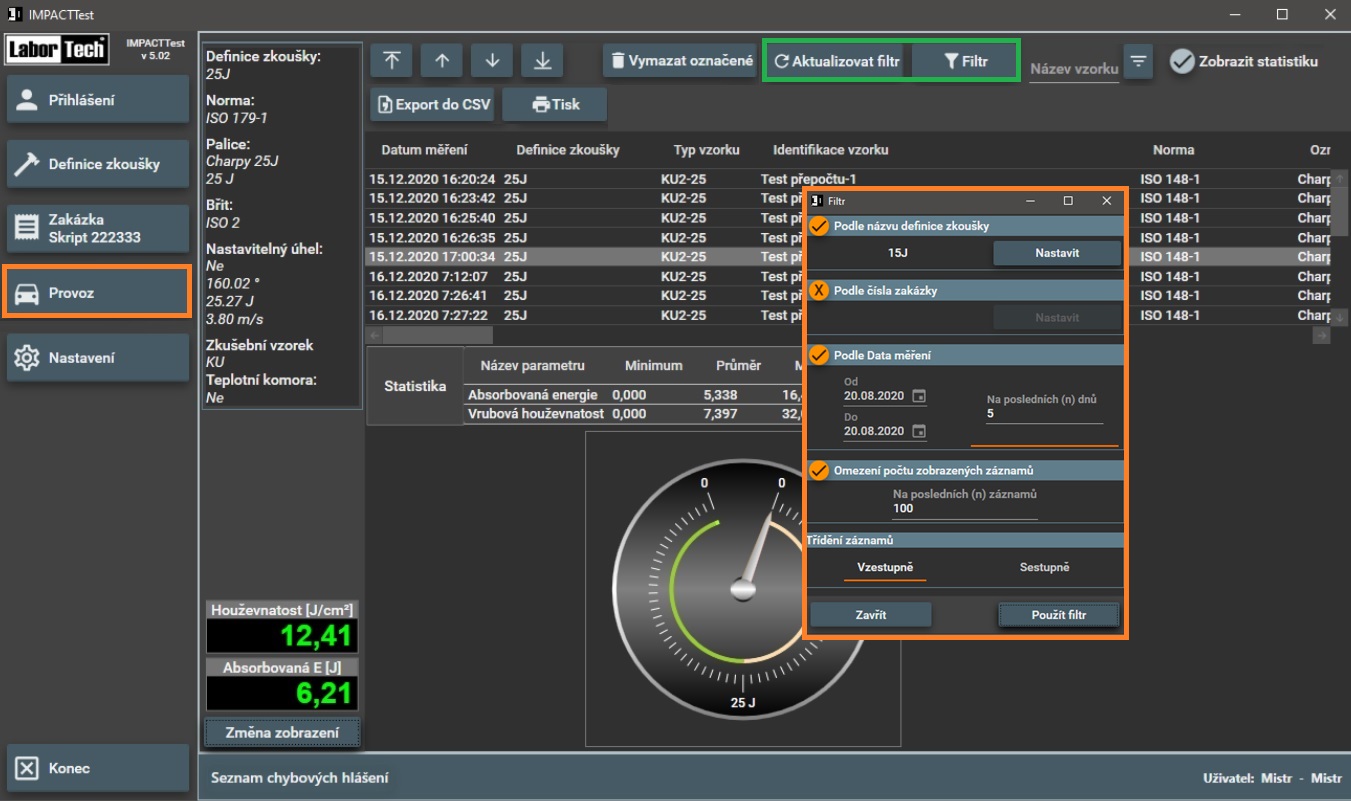

MAIN – OPERATION SCREEN – WORKING WITH DATA

Navigation buttons on the touch screen allow easy movement between records – to the first, last, or move forward or backward one. The “Export to CSV” button exports selected records to a CSV file, with the export status displayed in the status bar. The “Delete selection” button allows deleting marked records, individually or in bulk. The “Print” button prepares printing of the selected line, or prints only the first marked record. The “Filter” button is used to filter records by test definition, with the default setting showing values of the same definition name. The “Update filter” button refreshes data according to the current filter settings, allowing you to view data without changing the active test definition. The “Statistics” button calculates and displays statistics from the currently displayed sample list, providing an overview of average values, deviations, and other data.

MEZERA

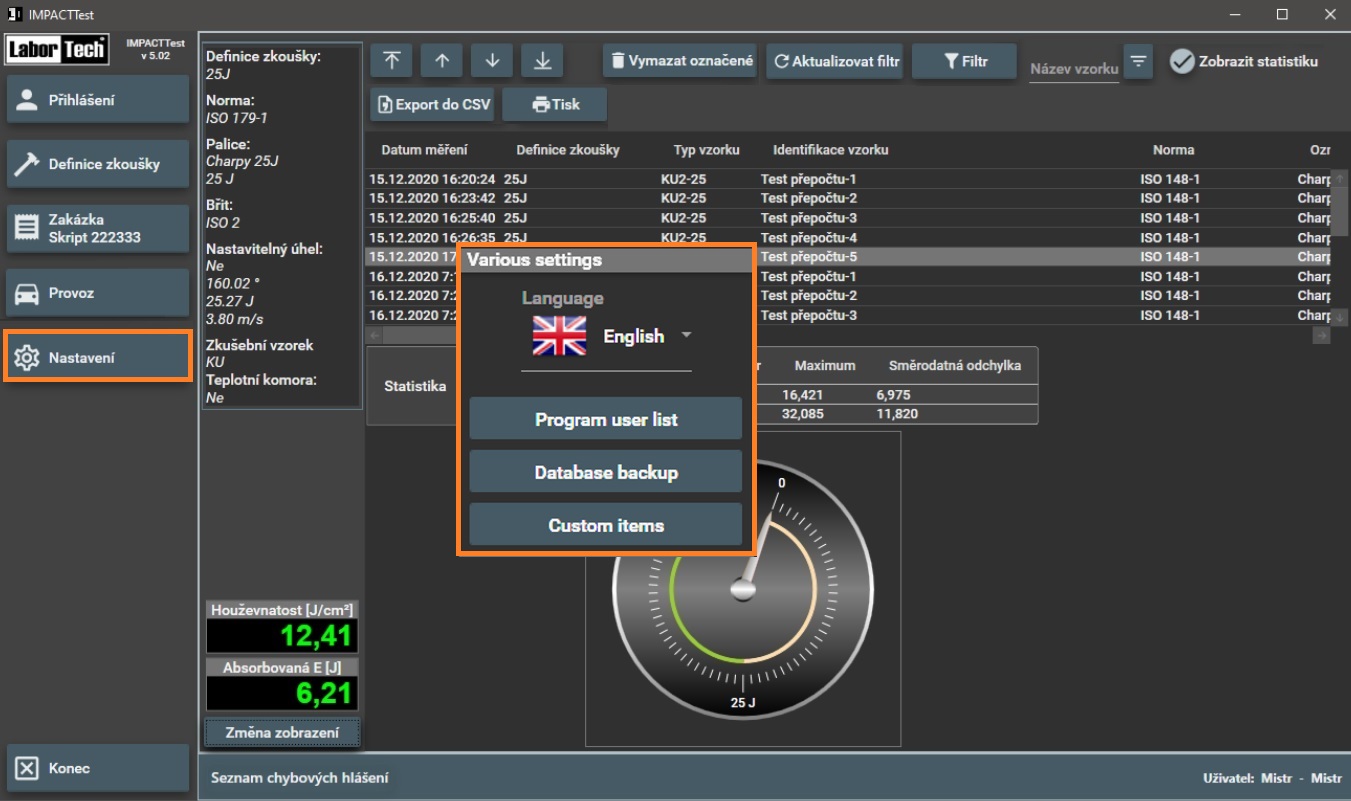

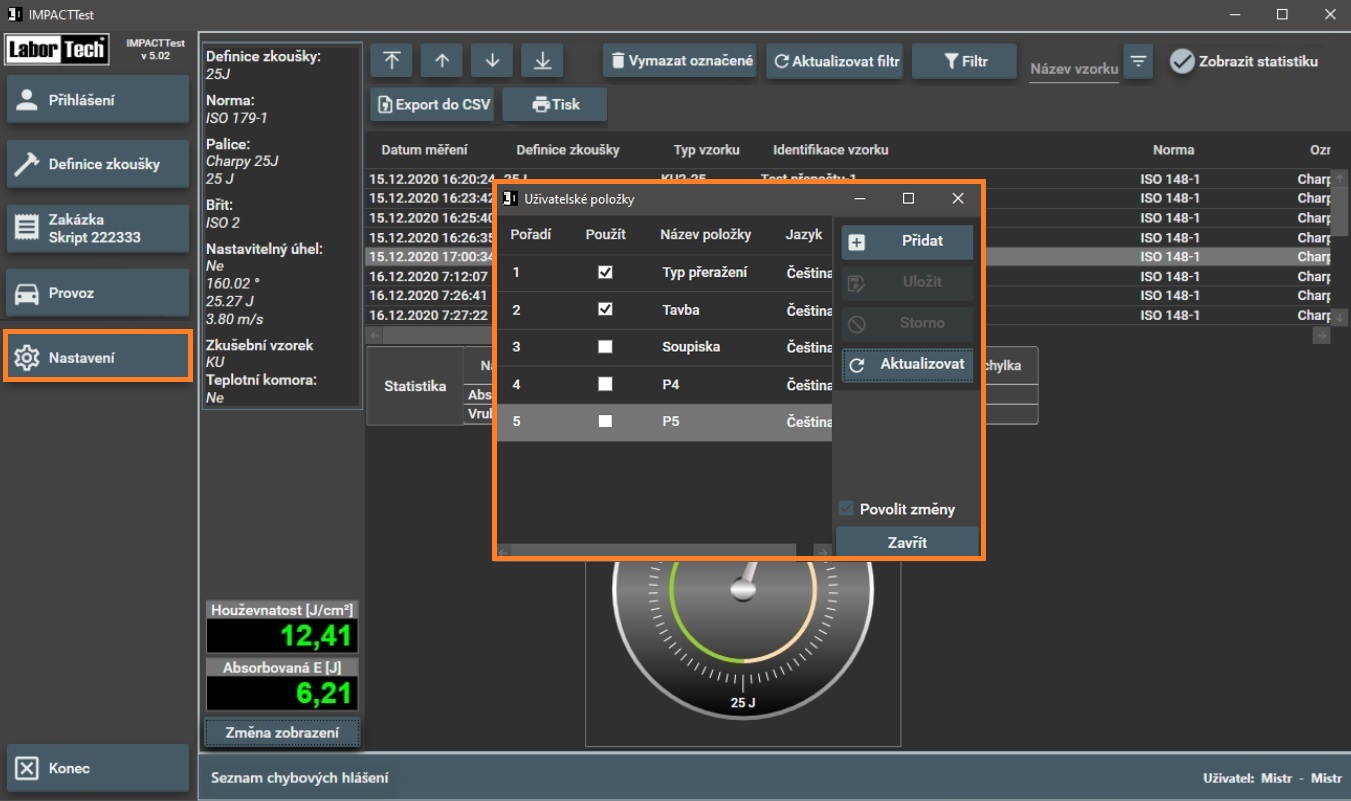

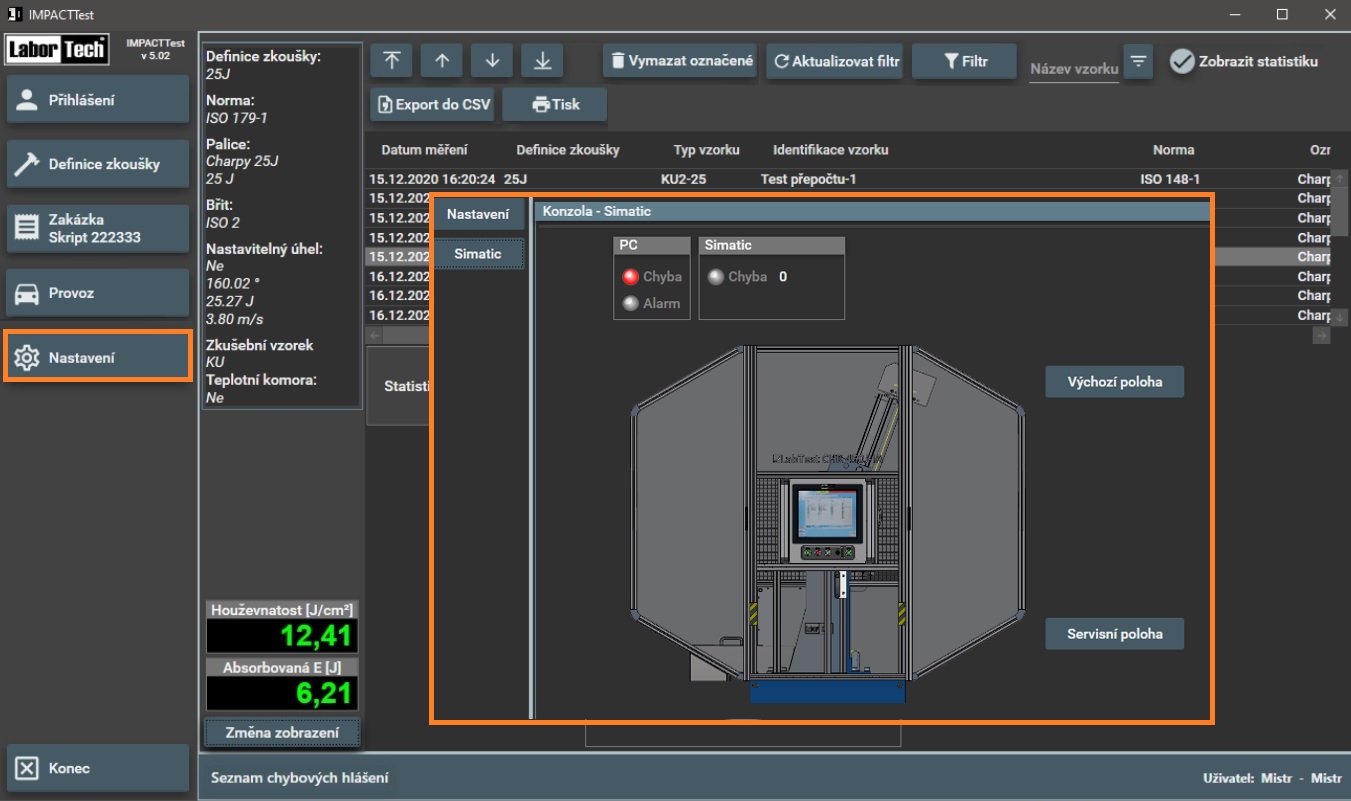

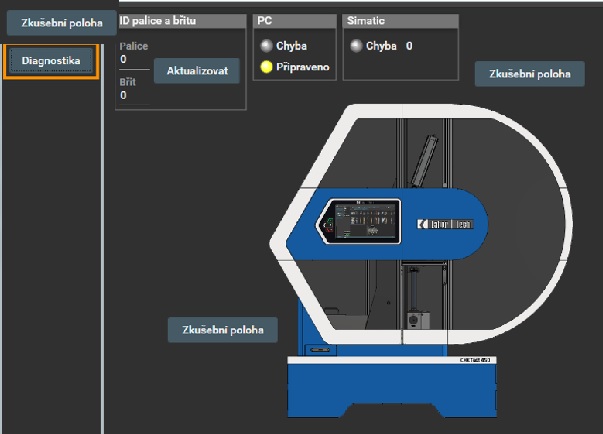

PROGRAM SETTINGS

The button for displaying program settings opens the corresponding menu in the right working part of the window. Here the user can enable automatic selection of the last used test and job definition. The menu allows for management of the user list, backup of the database that stores all data including graphs and user settings, and definition of user item names that form the column names in the measured data database. The user console is used for machine settings and entry of six user items. It also provides information about the machine status and for users with “Master” rights offers buttons for performing the initial or service position. User item names can be set separately for each program language, which allows the program to be adapted to specific user requirements.

MEZERA

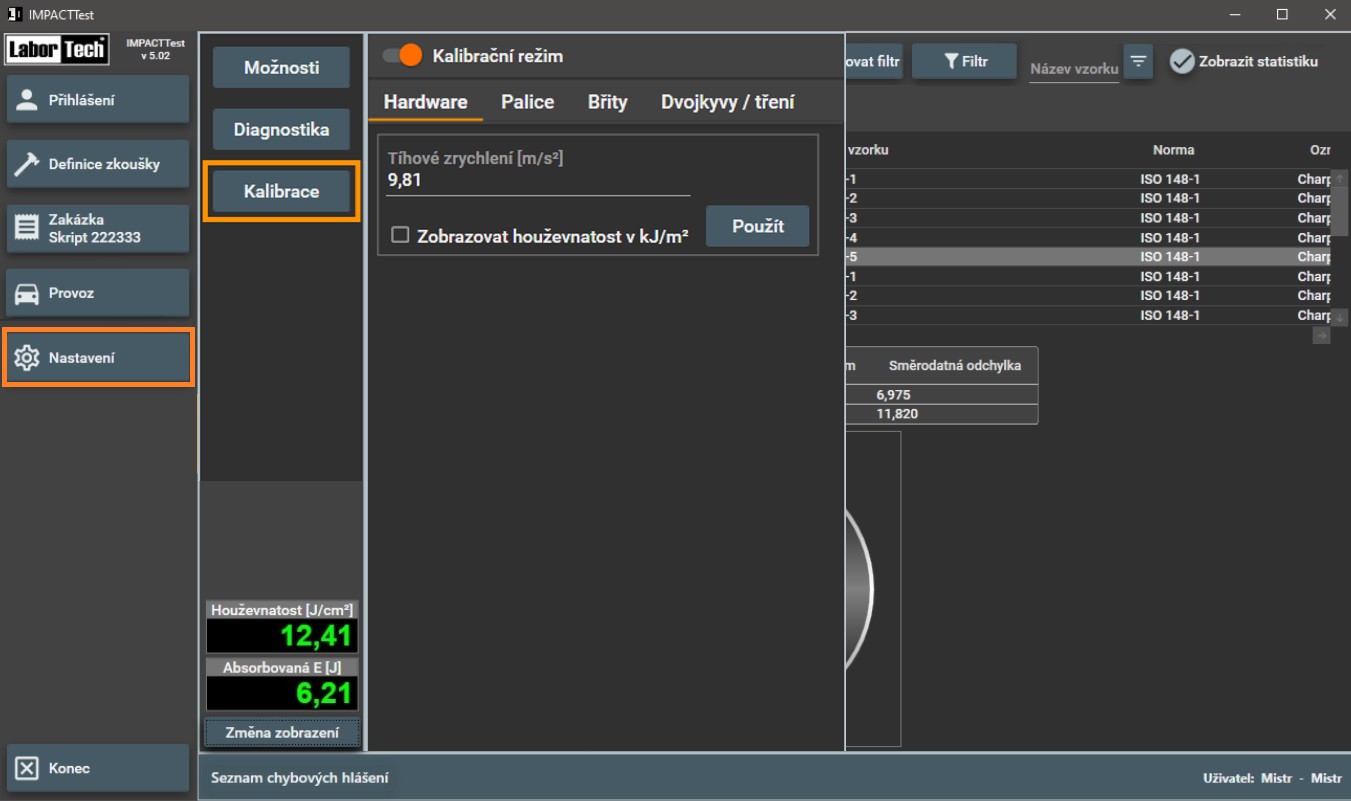

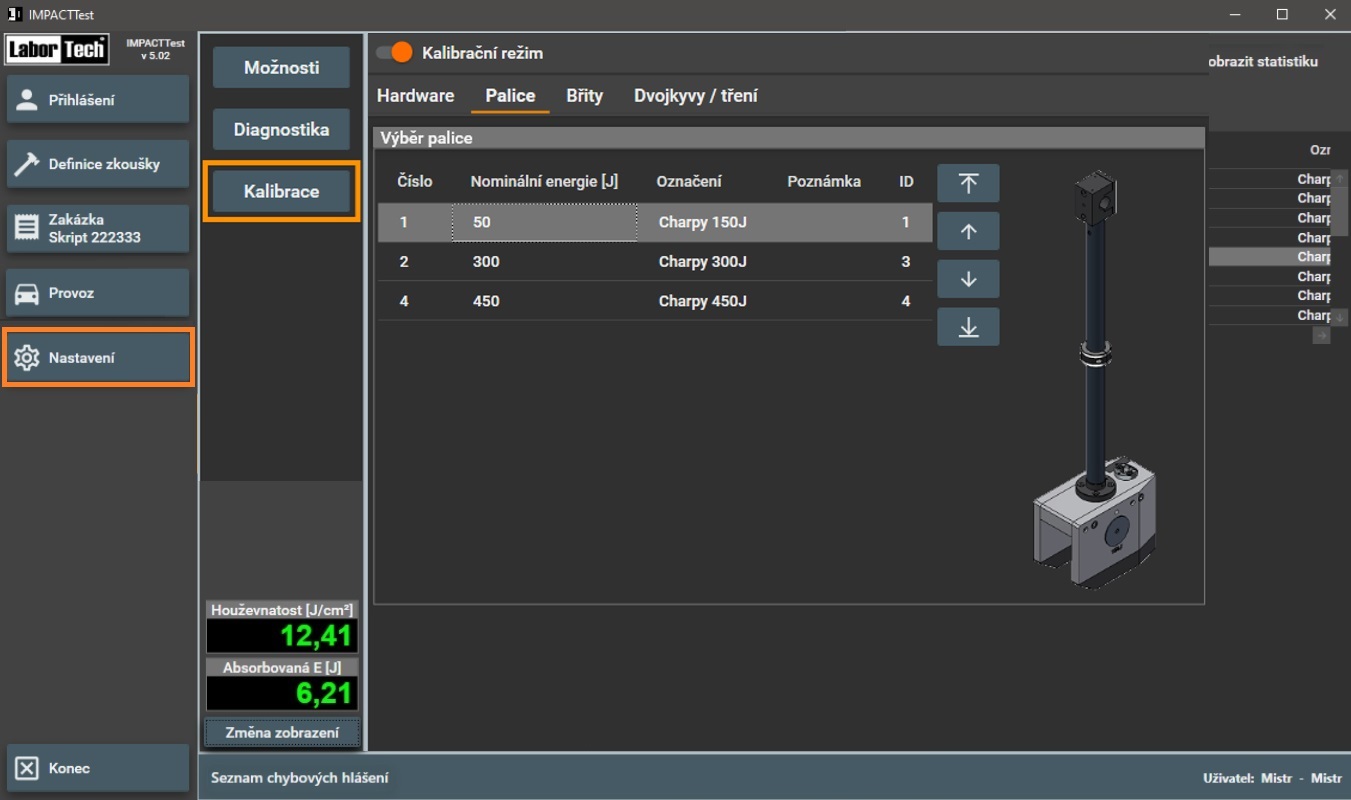

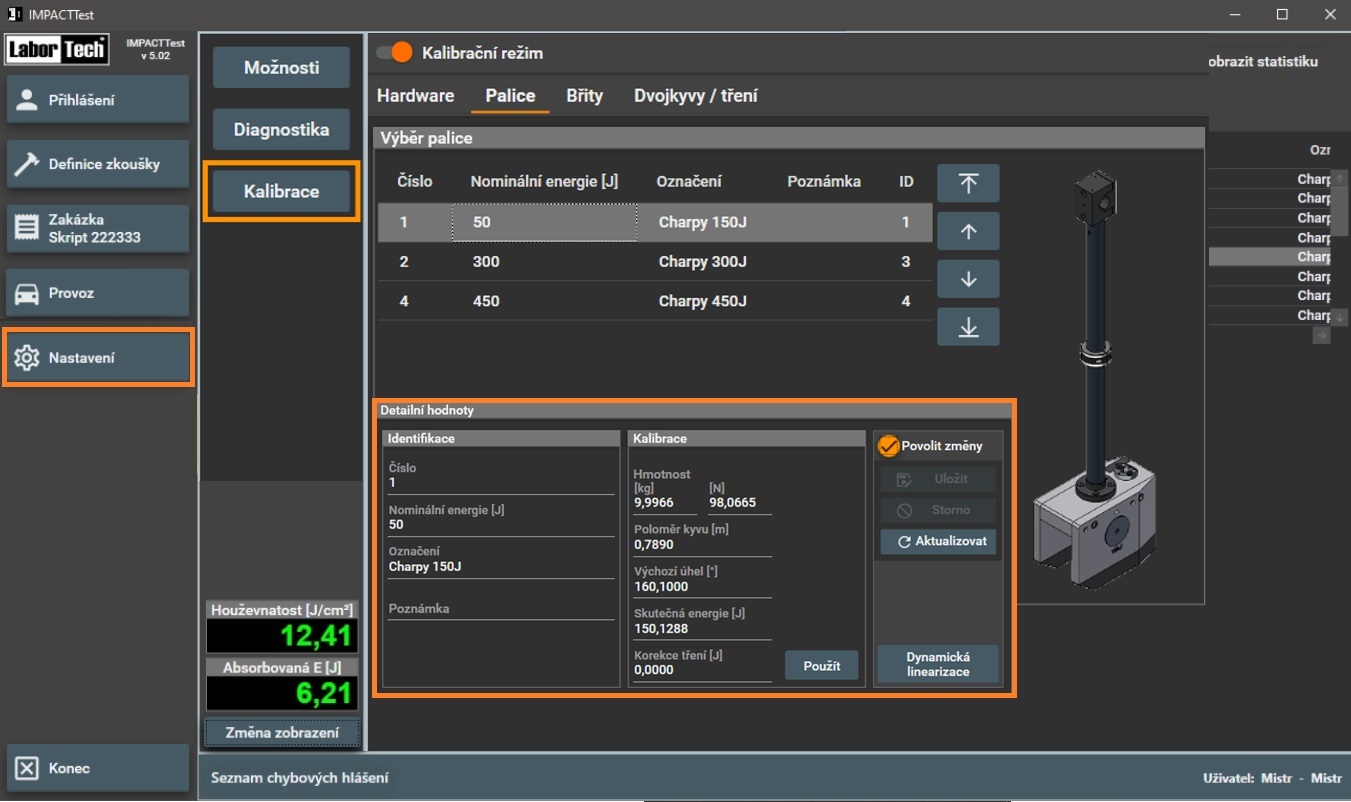

PROGRAM SETTINGS – CALIBRATION

The device is calibrated in accordance with ISO 148-2, ISO 14556, ASTM E23, ASTM E2298 and GOST 9454-78. Activating the calibration mode allows access to the calibration tabs, which include setting the gravitational acceleration at the installation site and the ability to switch the notched toughness units. The selection of the calibration stick or edge is done by clicking on the appropriate row or button, with the currently selected item graphically highlighted. Measured values, such as angle, height and impact work, are displayed in real time during calibration. The “Double swing / friction” tab allows checking the double swing time, the hammer friction torque and displaying the current values. Calibration is supported by controls such as the “Zero angle”, “Home angle” and “Hammer lock” buttons. This mode ensures accurate machine setup and allows comprehensive control over the calibration process.

MEZERA

–

Do you have any questions about our software?

Please feel free to contact our application engineers.

We look forward to hearing from you.

–

MEZERA

EXPANSION MODULES FOR THE IMPACTTEST SOFTWARE – BASIS

Basic software that can be easily expanded with additional modules.

IMPACTTest MODULE – I – INSTRUMENTATION

Automatic recording of instrumented test results including retroactive modification and evaluation according to EN ISO 14556:2015. Recording of multiple curves, zooming using ZOOM – determining x, y coordinates for individual samples, etc. Dynamic linearization according to ASTM E 2298. Linearization of the instrumented cutting edge course including calibration according to EN ISO 148-2, ASTM E 23 and ASTM E 2298 Basic technical data: Sampling frequency – 4 MHz, A/D converter -16 bit, path resolution 0.07 mm

MEZERA

IMPACTTest MODULE – A – ADJUSTABLE ANGLE

Setting and holding of the test ram by a special magnetic coupling, which offers unprecedented possibilities for performing notch toughness testing associated with the development of new materials. Freely electronically adjustable starting angle with an accuracy of 0.05° without any angular limitation. Basic technical data: Pendulum impact speed – 3 to 100% (max. 5.5 m/s) Adjustable starting energy in the range: 7 to 100% Adjustable starting angle in the range: 15 to 100%

MEZERA

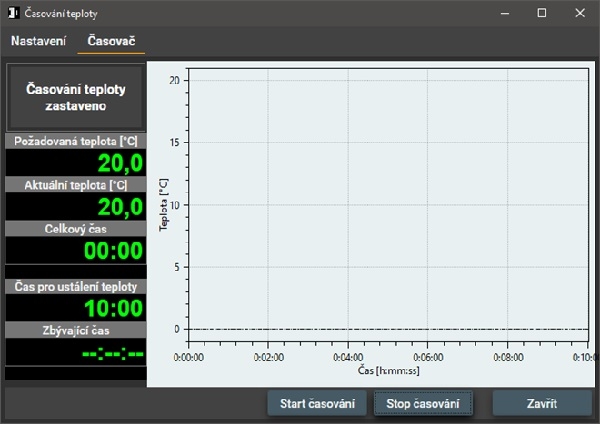

IMPACTTest MODULE – T – TEMPERATURE MONITORING

Automatic temperature monitoring and mutual communication with the LABCool 21 cooling chamber. Setting parameters – coolant temperature tolerance, temperature stabilization time setting, temperature stabilization time setting after a drop outside the tolerance, X and Y axis unit settings in the graph, tolerance field, etc. After the timing is completed, the information message will change to green and the “Start test” button on the machine panel will be unlocked. Display – desired temperature, current temperature, total time, temperature stabilization time, remaining time, graphical display of the progress, etc.

MEZERA

IMPACTTest MODULE – BR – ROBOT- X-RUNNER

The BR software module is designed for the BLUE RUNNER and YELOW RUNNER robotic systems from LABORTECH. These systems were created primarily to minimize the influence of the operator on the reproducibility of test results by setting and breaking samples within 5 seconds, as required by the EN ISO 148-1 standard. Automatic selection of samples from a defined container. Communication and control with a temperature chamber for temperatures up to -95 °C, including a container system. Communication with the optical inspection of samples OPTOLab 55 II, including database exchange of measured data. This module can be used for both the BASIS module and for modules I, A or combined IA.

MEZERA

IMPACTTest MODULE – O – SAMPLE DIMENSIONS

Data acquisition module from the OPTOLab 55 II optical system. Display of measured values with given tolerances directly on the sample. Saving all values in the database with filtering of individual parameters. Data transfer to the system: height, length, width of the sample, axis distance, height under the groove, groove angle, axis angle, root radius, and side angle

We will be happy to advise you on the right choice of machine…

Contact

LABORTECH s.r.o. , Rolnická 1534/130a, 747 05 Opava, Czech Republic

News & Events