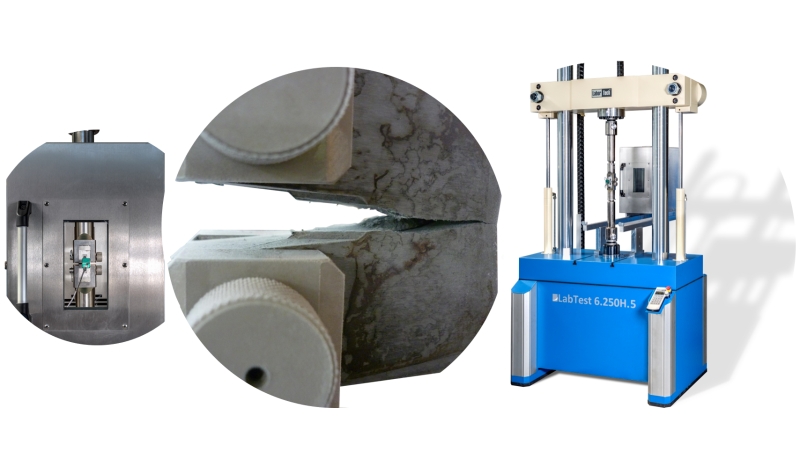

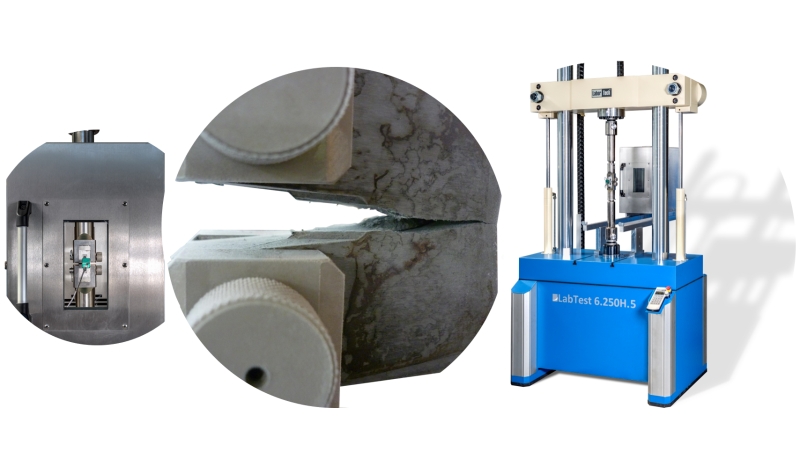

Dynamic servohydraulic testing machine LabTest 6.250H.5

has recently become part of the testing laboratory of the Ukrainian company INTERPIPE NTRP, a global manufacturer of steel pipes and railway wheels. This testing machine, equipped with accessories such as a temperature chamber or a contact strain gauge, was designed and conceived to provide testing and measurement of fracture toughness in CT metal specimens with a load of up to 250 kN and a maximum test frequency of 50 Hz in a dynamic test mode. The tests are performed according to ASTM E399 and ISO 12737 standards.

ASTM E399 and ISO 12737 describe the determination of fracture toughness of metallic materials by fatigue testing of so-called “pre-cracked” specimens 1.6 mm (0.063 in) or more. The force is applied either in tension or in three-point bending. Fracture toughness characterizes the resistance of a material to fracture in various temperature environments in the presence of a sharp crack under linear-elastic stress and strong tensile stress.

All our axial servohydraulic dynamic testing machines are driven by HAD series hydraulic units with a constant pressure of 210 or 280 bar. These hydraulic power units are fully compliant with the Industry 4.0 system, thanks to the remote connection and constant evaluation of the sensors, which ensures permanent condition monitoring and prediction of possible unit failures. A special anti-noise acoustic cover with an integrated cooling system guarantees noise reduction below 65 dB and cooling of the entire hydraulic unit.

HAD hydraulic units are able to intuitively regulate the pressure and amount of oil in the cylinder, thus reducing the oil consumption and energy consumption of the system.

Want to know more about our dynamic servohydraulic machines? Write to us or give us a call, we will be happy to answer your questions.

LABORTECH TEAM