The Combined Robotic Workstation X-RUNNER TANDI by LABORTECH represents a cutting-edge solution for automating testing processes, integrating advanced technology and state-of-the-art equipment to ensure maximum efficiency and measurement accuracy. The workstation is equipped with the LabTest 6.250 E.3 testing machine, designed for tensile testing. This machine features a dual VIDEOEXTENSOMETER for contraction measurement and the LME-50 contactless measuring unit for precise measurement of test specimen dimensions.

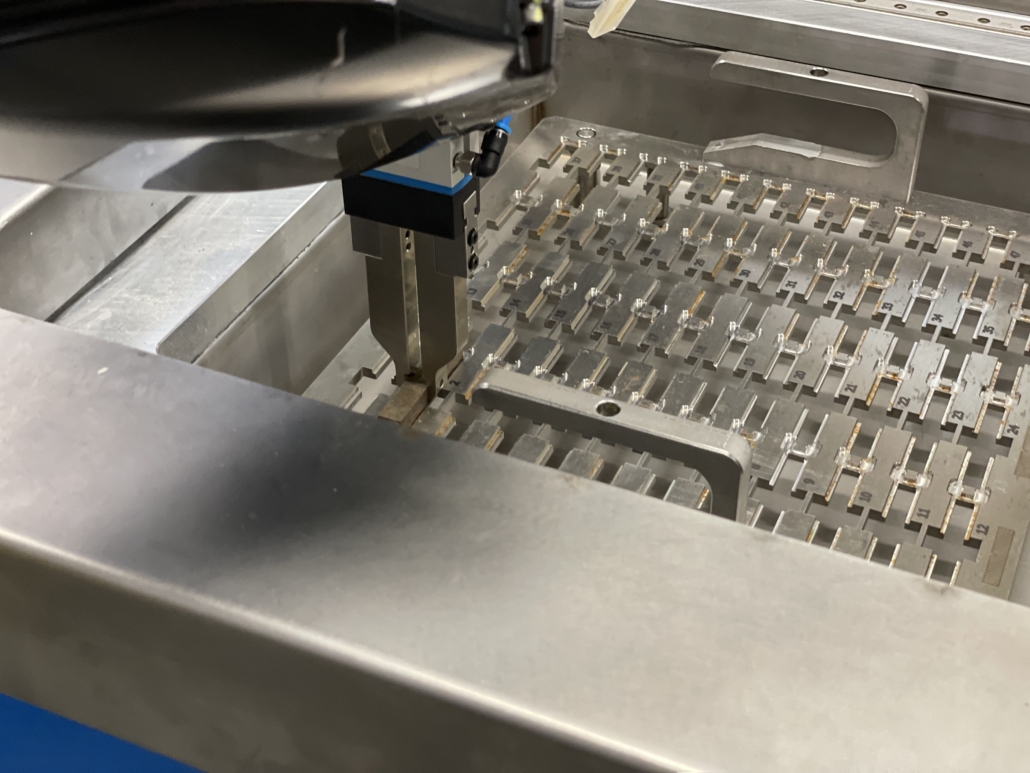

Another key component of the system is the new CHKTest 450 impact hammer with IMPACTTest software. This hammer is designed for impact testing, featuring the LABCool – AUTOMATIC cooling chamber, which ensures optimal conditions for testing impact specimens measuring 50x10x10 mm at temperatures down to -80°C. At the entry point for impact tests, the OPTOLab 55II system automatically selects good and bad specimens, enhancing the reliability of the entire testing process.

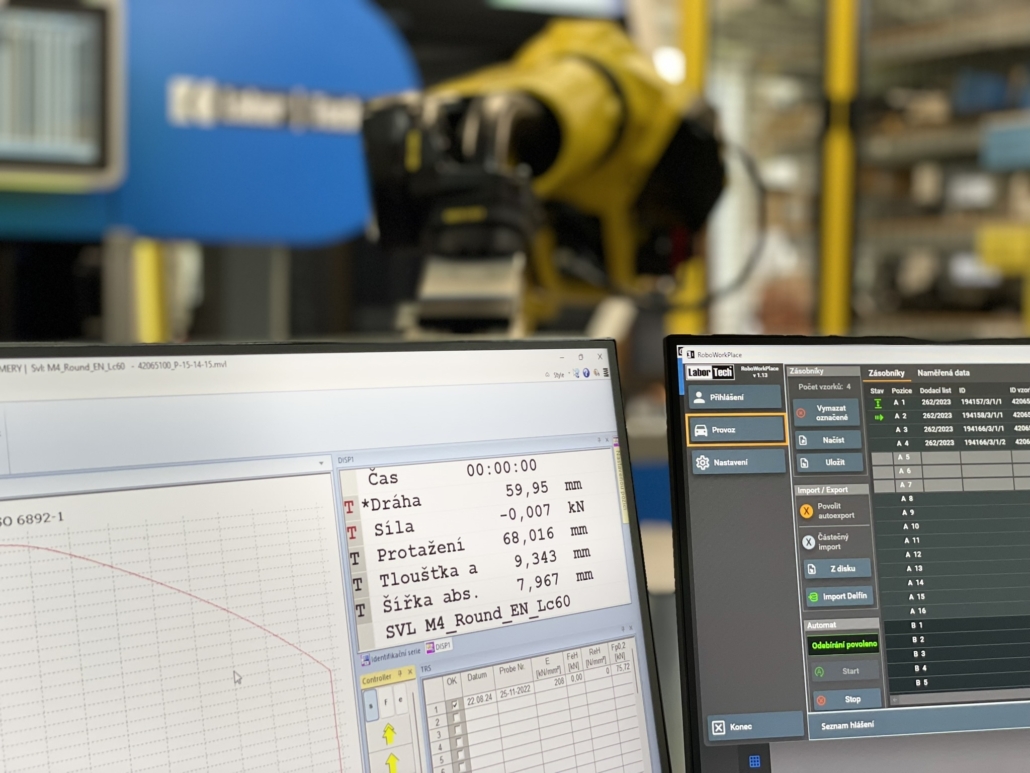

The entire X-RUNNER TANDI system is managed by RoboWorkPlace software, which ensures seamless integration and automation of all processes, including data transfer to the company network. This comprehensive system allows for fully automated operation with minimal human intervention, increasing productivity and eliminating the risk of human error. The Combined Robotic Workstation X-RUNNER TANDI is, therefore, an ideal solution for modern testing laboratories that demand the highest standards of accuracy, reliability, and efficiency.

TEAM LABORTECH