LABORTECH s.r.o. proudly presents its new electromechanical testing device designed for testing vehicle axle jacks. This robust system is engineered for demanding off-axis load simulations up to 100 kN, offering unique technological solutions in the field of durability and reliability testing of automotive components.

The device enables load simulation in the Z direction through a sophisticated system operating in force and position control modes. Movements in the X and Y directions are powered by high-performance AC servomotors, precisely simulating real-world conditions. Accurate off-axis load measurements are achieved using three load cells positioned at 120° intervals, calibrated according to ČSN EN ISO 7500-1. The system also features a controlled drive shaft with torque measurement capabilities, enabling precise simulation of axle jack operation during tests.

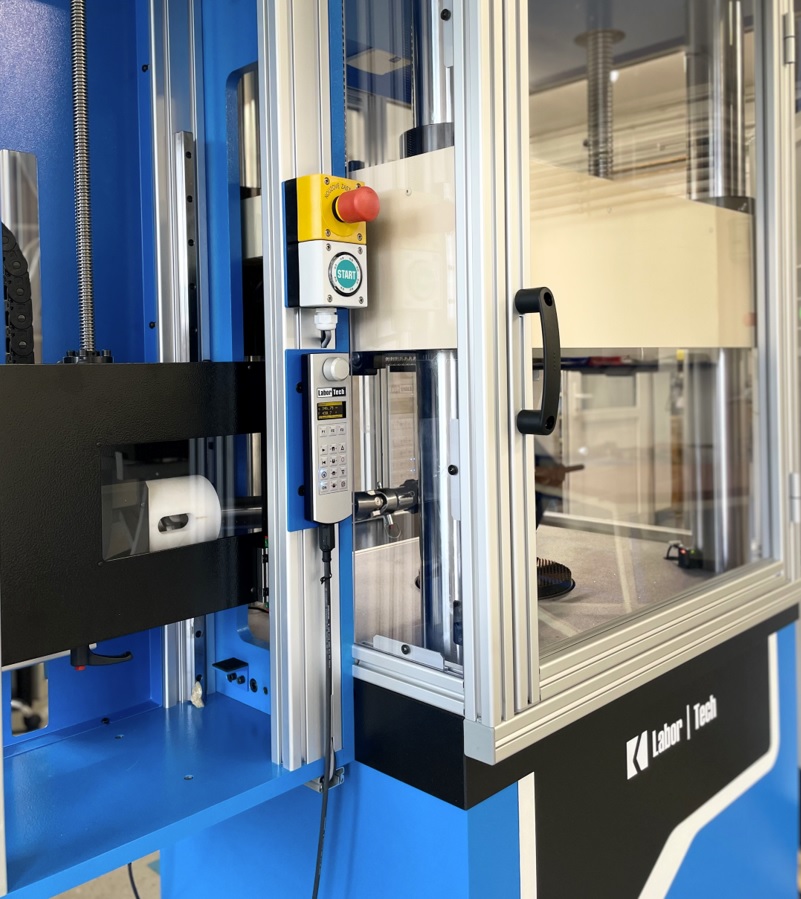

Safety is ensured by a protective enclosure compliant with directives 2006/42/EC and EN ISO 14120:2017, guaranteeing maximum operational safety. Advanced system control is facilitated via a PC with a TOUCH LCD monitor and intuitive AXJTest software, providing users with precise management and configuration of tests.

This testing system is particularly suited for simulating various load conditions, such as testing jacks for different types of vehicles, including SUVs, electric vehicles, and plug-in hybrids. It enables load curve simulations for different vehicle weight conditions, such as empty, partially loaded, or fully loaded states. The system has been successfully deployed for axle jack testing for premium automotive brands, including BMW, VW, ŠKODA, AUDI, and more.

The LabTest 6.100.9 AXLE – J testing device combines precision, robustness, and safety, making it an ideal choice for companies seeking cutting-edge technology to ensure the longevity and reliability of automotive components.

LABORTECH TEAM