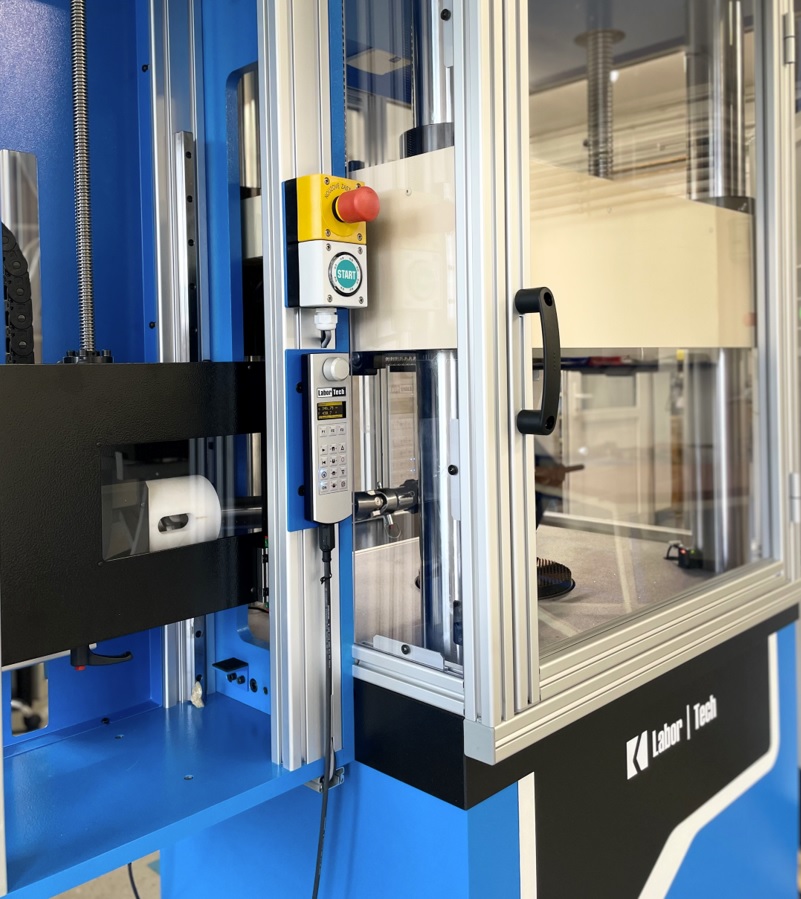

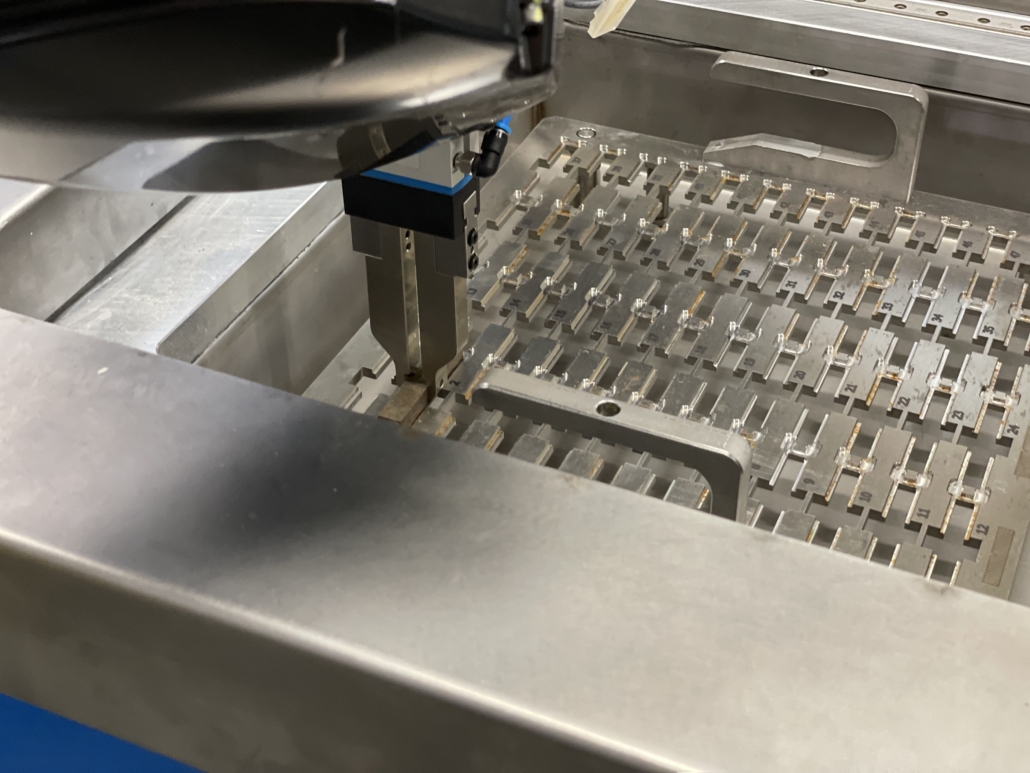

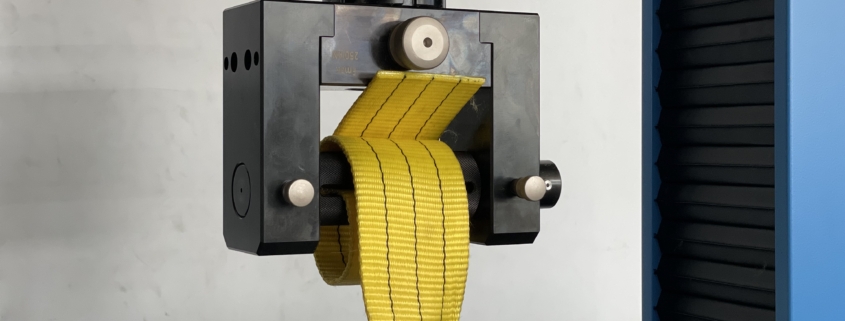

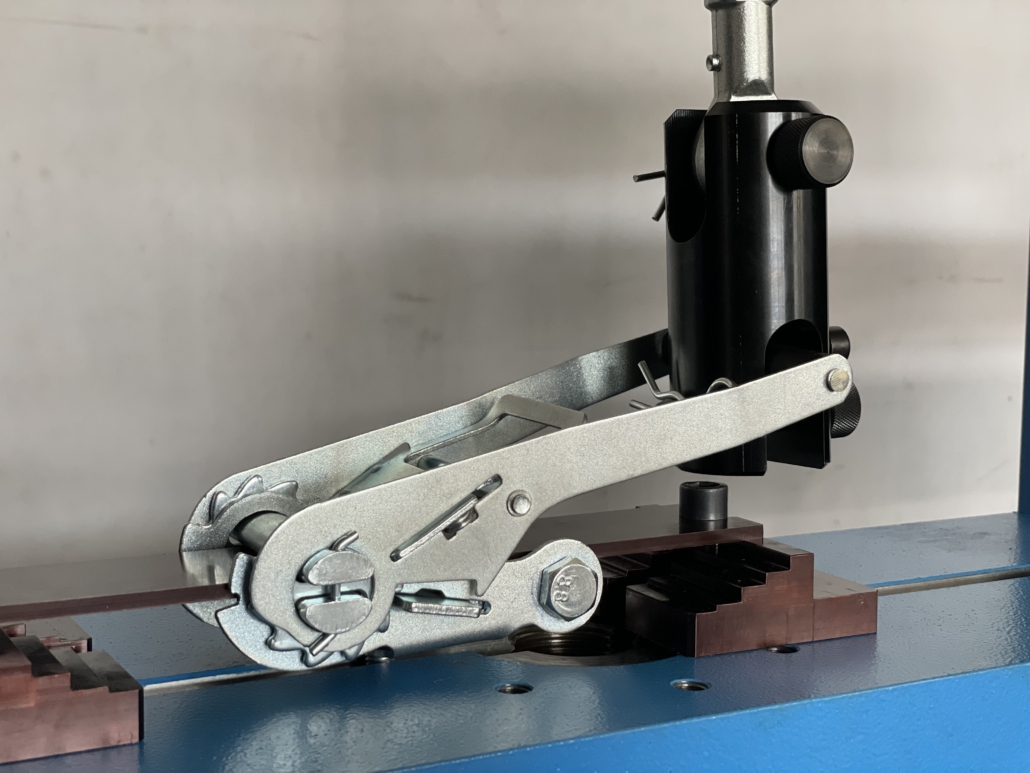

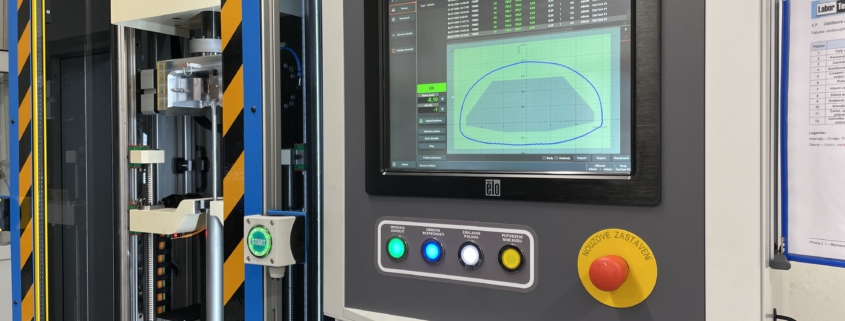

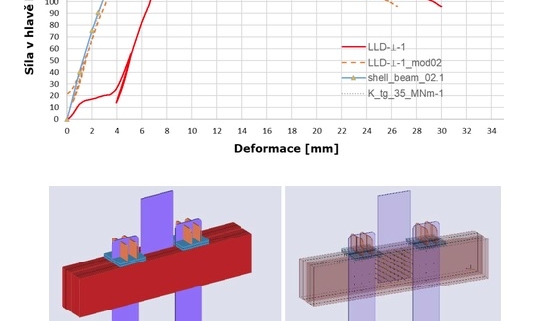

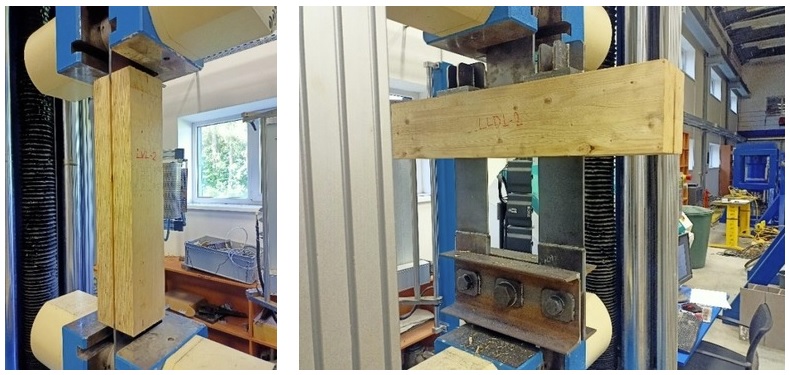

LABORTECH once again demonstrates its innovative capabilities by introducing the new HAG 3 – SIMPLE hydraulic unit, which is the result of a short, high-quality, and intensive development process combined with precise engineering. The developers focused on maximum efficiency, ease of operation, and an optimal balance between performance and cost. Thanks to modern technologies and the use of advanced control algorithms, they have created a unit that not only meets the strictest requirements for tensile testing with hydraulic wedge grips but also provides a high level of user comfort and operational reliability.

Key Features of HAG 3 – SIMPLE:

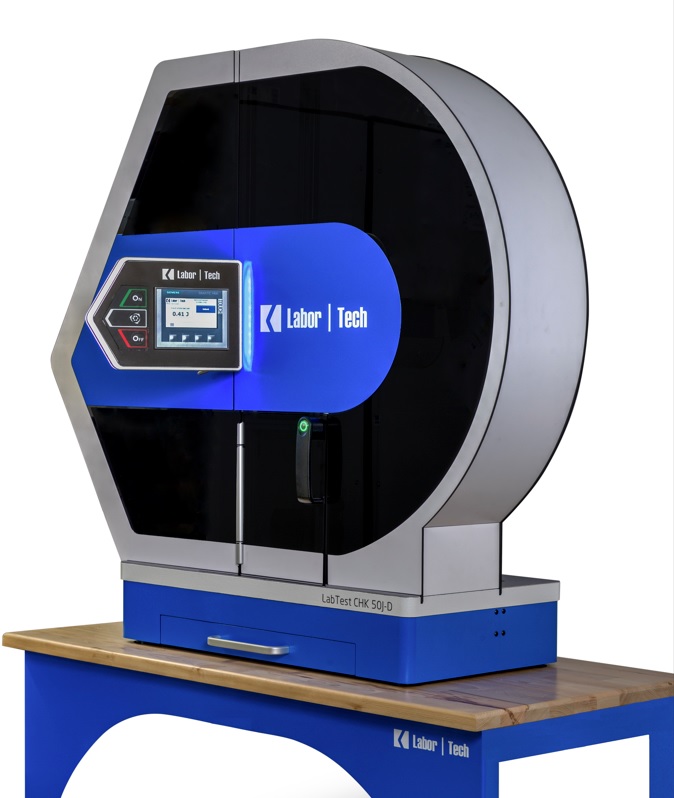

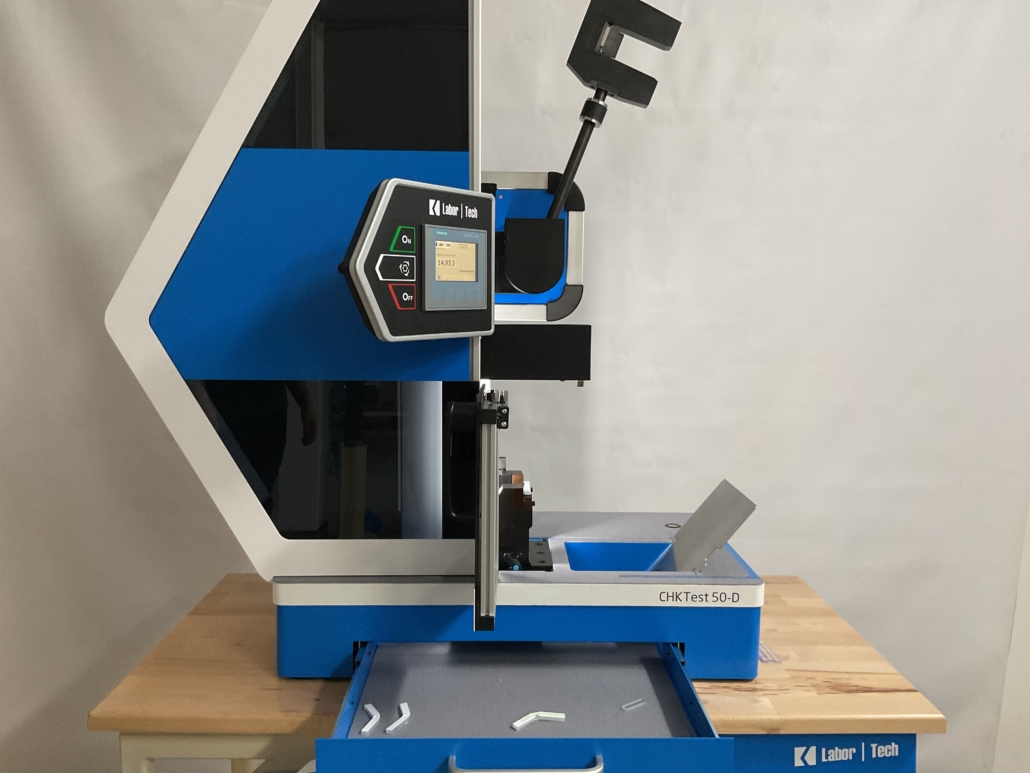

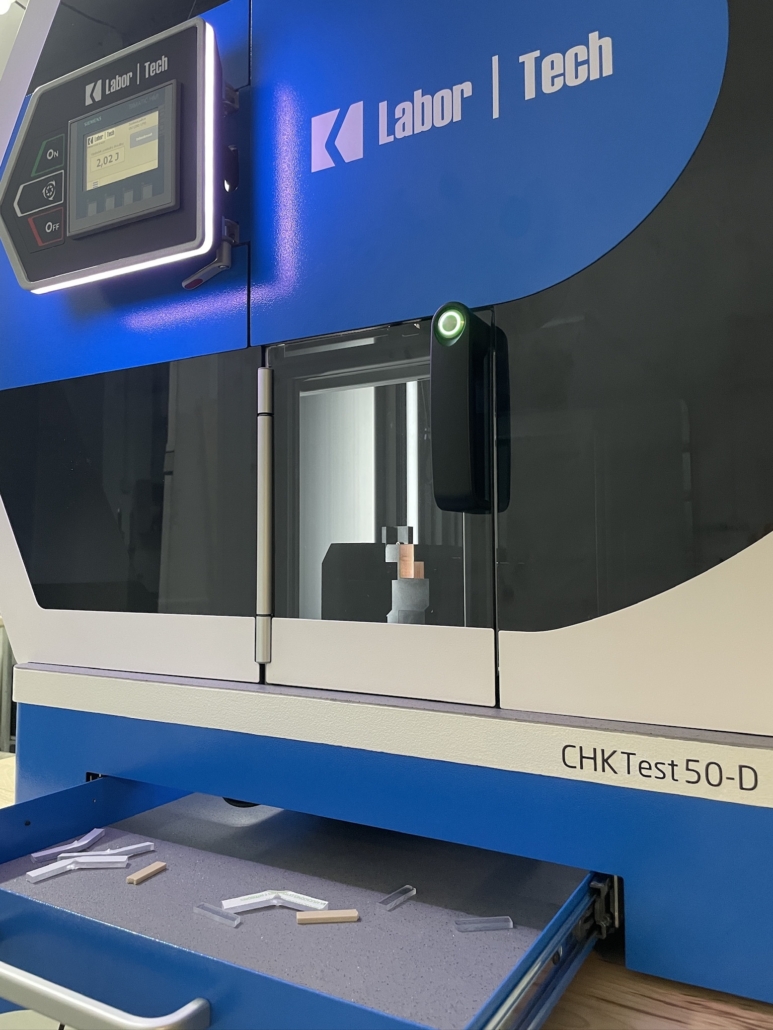

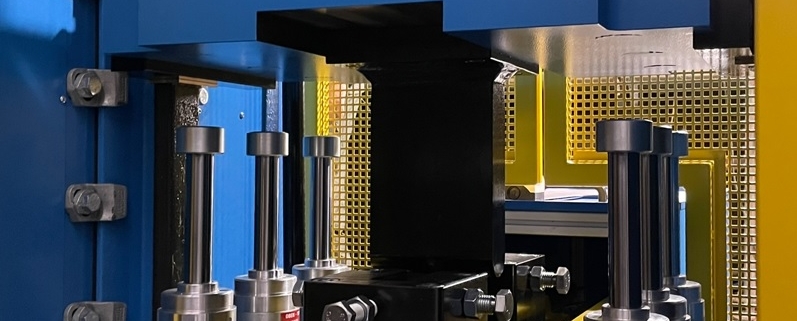

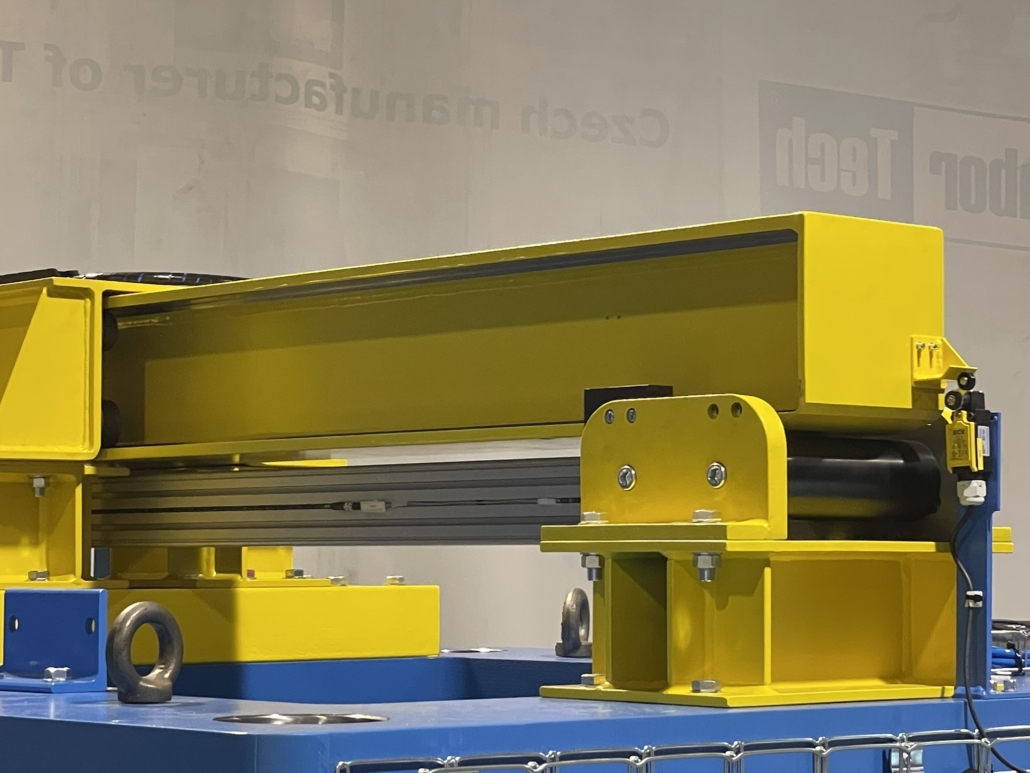

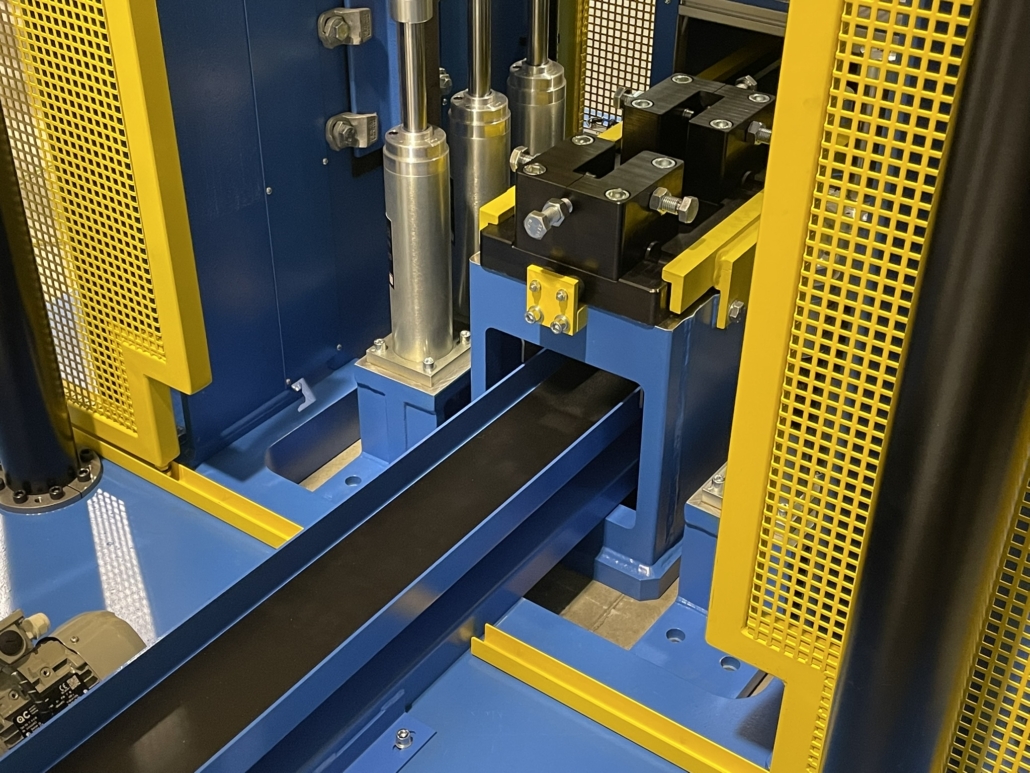

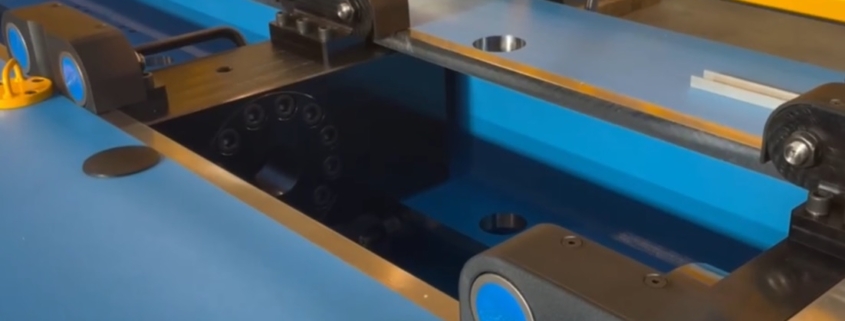

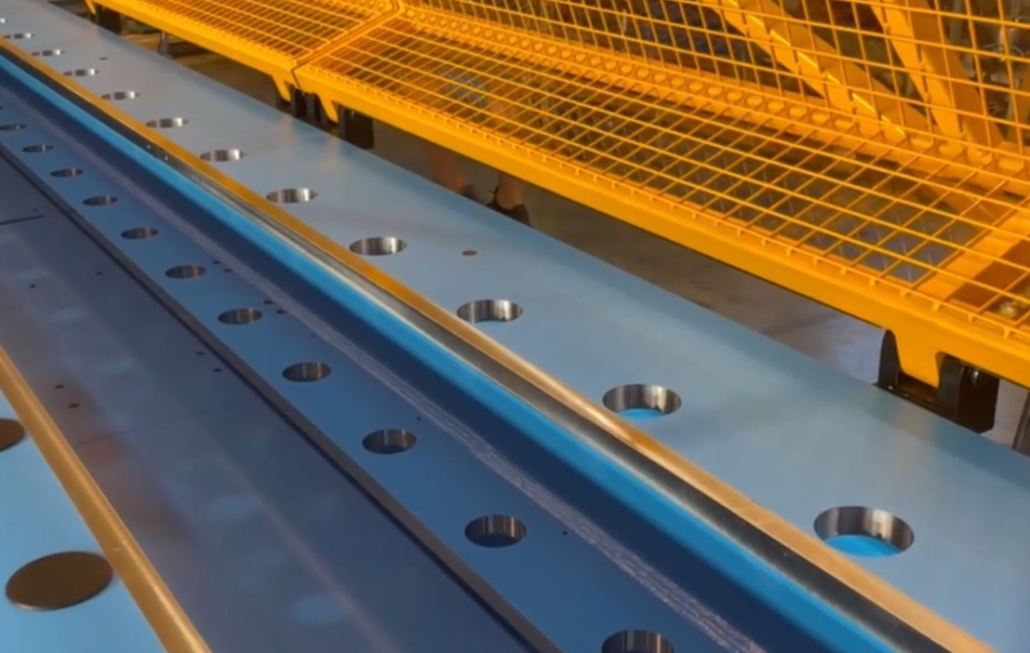

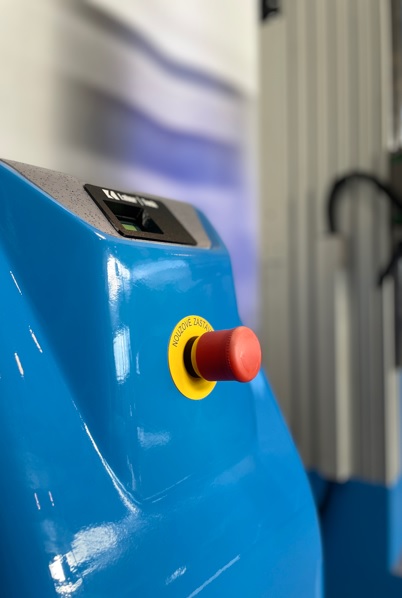

Modern Design: The new EDITION 30 design not only highlights technological progress but also contributes to better ergonomics and easier handling.

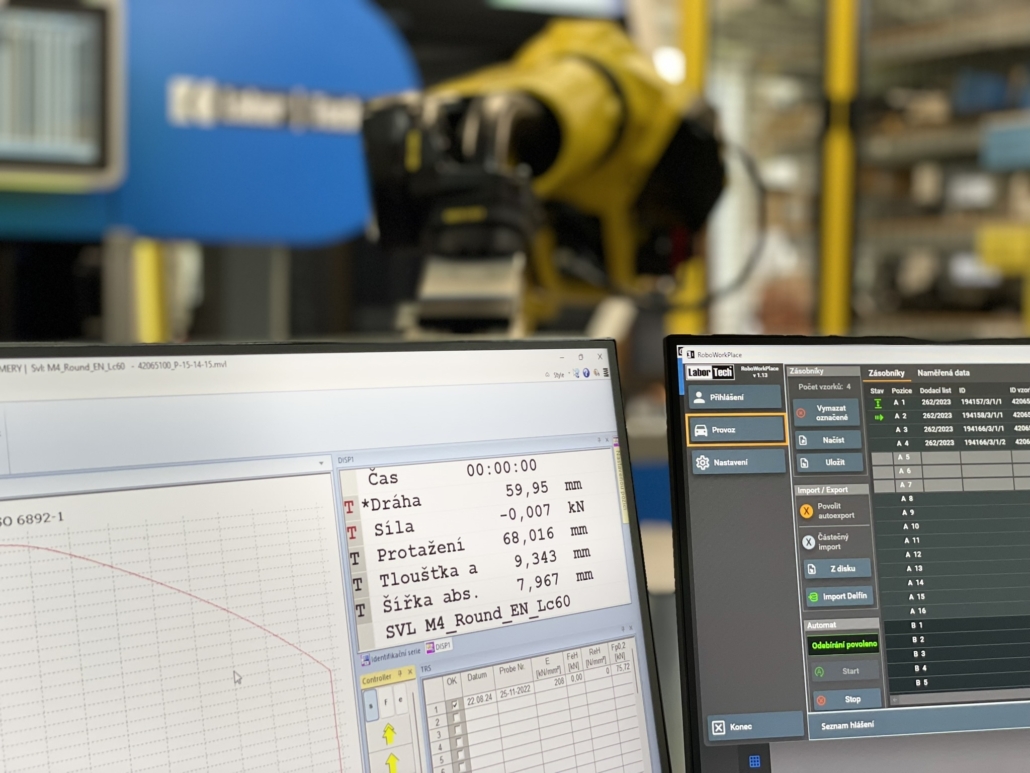

Integrated Diagnostics: Thanks to the intelligent SIMATIC system, efficient diagnostics and operational monitoring are ensured, significantly increasing reliability and minimizing unplanned downtime.

230V Power Supply: Standard voltage power supply allows easy integration into various work environments without the need for special electrical modifications.

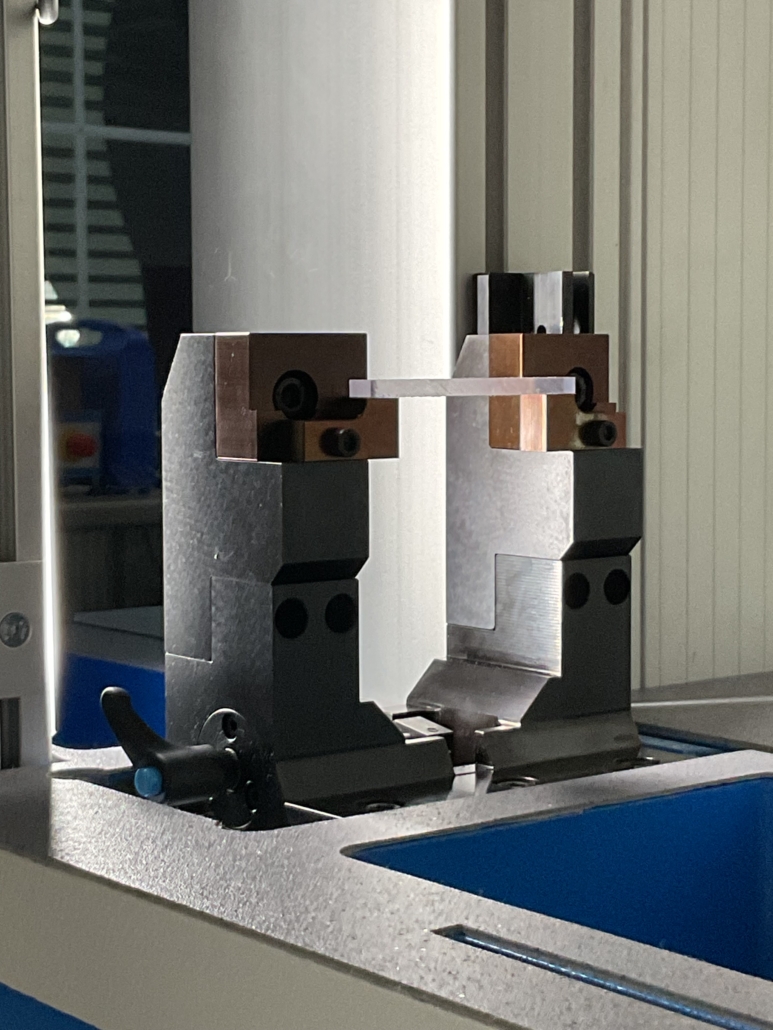

Easy Handling: A compact design and thoughtful construction simplify handling, installation, and maintenance interventions.

Ecological Operation: Designed with ecology in mind, the optimized hydraulic circuit reduces oil consumption and the overall environmental impact.

Low Noise Levels: Noise-reducing covers and an optimized pump operation process ensure reduced noise levels, improving working conditions.

Minimal Maintenance Requirements: High-quality components and a sophisticated diagnostic system minimize the need for frequent maintenance, reducing operating costs.

Economic Efficiency: With low energy consumption and an optimized hydraulic system, the HAG 3 – SIMPLE is highly cost-effective, positively impacting overall operational expenses.

LABORTECH hydraulic units are designed to meet the most demanding requirements of servo-hydraulic testing machines and systems. With a strong focus on ecology, low noise levels, economic efficiency, and easy maintenance, the HAG 3 – SIMPLE is an ideal choice for modern testing laboratories and industrial operations.

TEAM LABORTECH