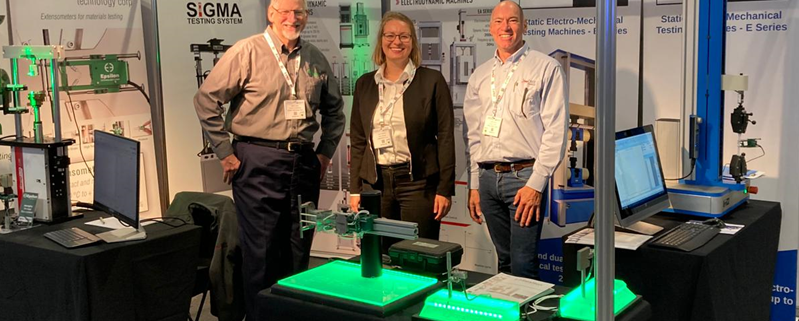

In the period from 29 to 31 January 2024, an exceptional meeting of business partners from Germany, Austria, England, Italy and Poland took place at a partner day, organized by LABORTECH. This exceptional meeting was an opportunity to share experience in the field of testing machine sales, and at the same time brought space for the presentation of the latest innovations, technologies and visions.

Exchange of experience and trading strategies

The main objective of the partner day was to exchange valuable experience in the field of sales of testing machines. Representatives of LABORTECH shared with business partners successful strategies, challenges and news in the field of material testing. The discussion focused on current trends in the industry and the opportunities that new technologies bring.

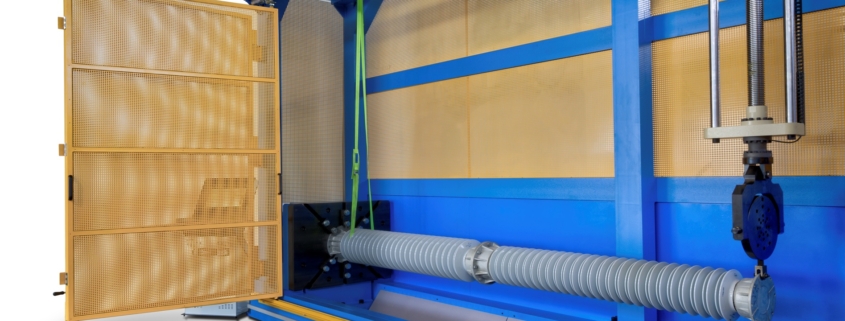

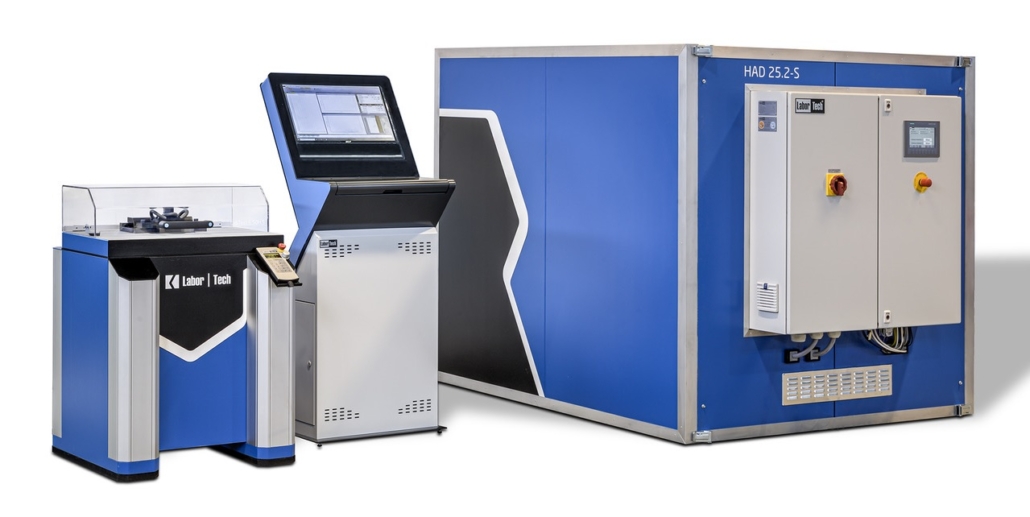

Innovation – presented in the Showroom

LABORTECH had the honour to welcome participants in its showroom in Opava. A modern robotic workplace for tensile and impact tests – X-RUNNER, which represents the pinnacle of automation in the field of mechanical testing of materials, was demonstrated here. Representatives of business partners had the opportunity to see how this technology produced by LABORTECH increases the efficiency and 100% repeatability of tests.

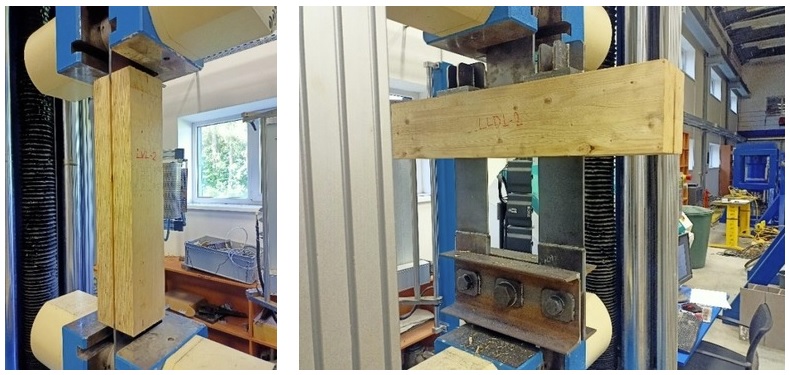

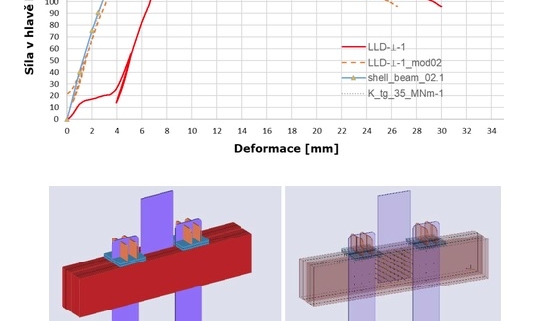

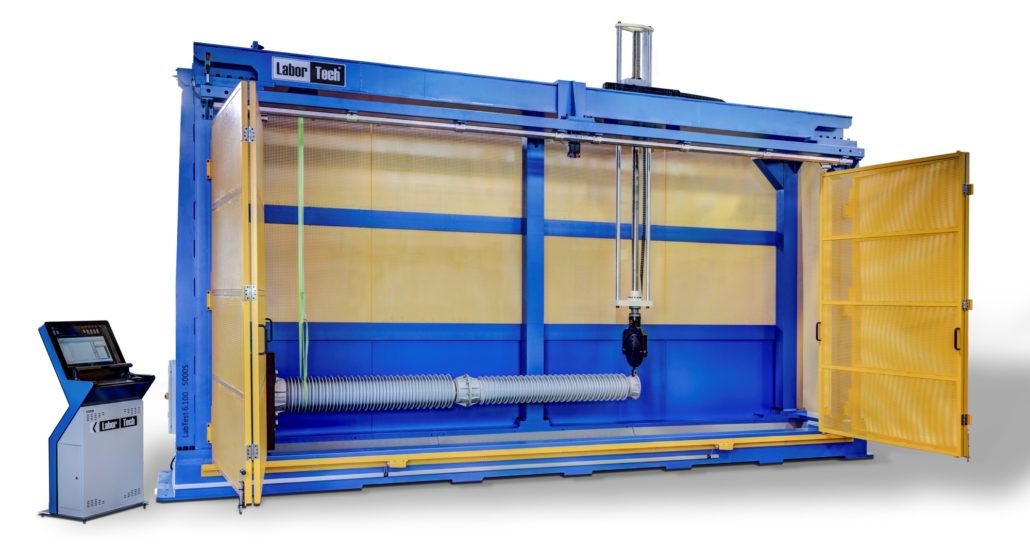

View of the production hall: production of testing machines

The partners of LABORTECH had a unique opportunity to look into the actual process of production of testing machines. LABORTECH Budišov nad Budišovkou hosted visitors in its production hall, where innovative equipment for mechanical testing of materials is manufactured and tested. Participants had the opportunity to get a feel for the new machines and better understand their design and functionality, as well as understand the details behind the quality and reliability of these devices.

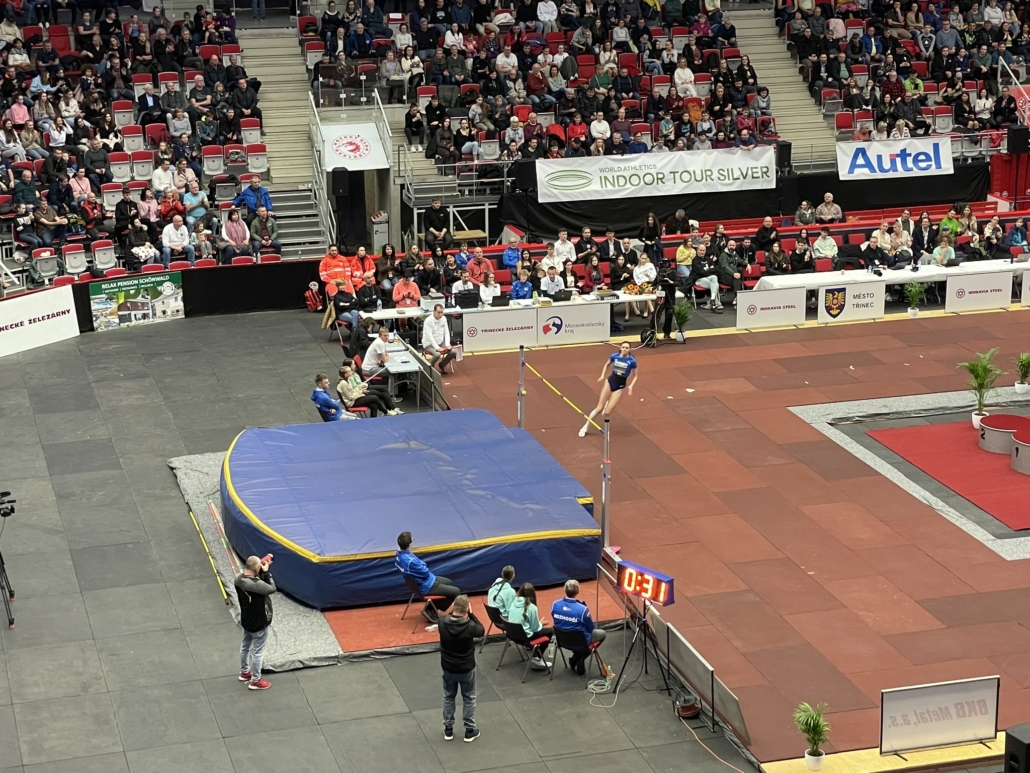

Thanks to Relax Pension Schönwald for their hospitality

The final negotiations and a pleasant end of the day took place in the Relax Pension Schönwald. LABORTECH would like to express its sincere thanks for the excellent hospitality and pleasant environment for the last discussions over a glass of wine. This moment of rest and informal meeting contributed to the strengthening of business relations and the creation of a pleasant atmosphere.

The Future of Collaboration

The partnership day with dealerships from Germany, Austria, England, Italy and Poland was not only about testing materials and innovations, but also about building strong business relationships and working together towards the future. LABORTECH is looking forward to further cooperation and meetings with business partners, in the spirit of innovation and continued development.

TEAM LABORTECH