COMPOSITES – TEST METHODS

Contact

Mechanical tests of composites are an indispensable part of the entire process of development, production and certification of carbon materials. These tests provide critical information on the mechanical properties of composites, which are key to the design and manufacture of composite-carbon products in various industries. The most common mechanical tests include tensile tests, bending tests, compression tests, impact tests and other specific tests focused on different aspects of the behavior of composites under different conditions.

The use of these tests is found in a wide range of industries. In the aerospace industry, composite materials are essential for the production of light and strong structures that reduce the weight of aircraft and increase their performance. In the automotive industry, composite materials are used to improve strength and reduce vehicle weight, which contributes to greater fuel efficiency and lower emissions.

In the construction industry, composites are often used to produce strong and lightweight structures such as bridges, buildings and walls, allowing for more efficient and durable structures.

TENSILE TEST

BEND TEST

PRESSURE TEST

SHEAR TEST

CYCLIC TEST

IMPACT TEST

MEZERA

MEZERA

Composites testing is therefore a key tool for ensuring the quality and safety of composite products and helping engineers and manufacturers optimize their design and properties for specific applications. The experts of our company are ready to provide you with additional information about the test standards, including the correct equipment for conducting these tests. Visit our Showroom in Opava and we will be happy to provide you with more detailed information and an offer based on your specific requirements. We look forward to your visit!

TEST STANDARDS FOR TESTING COMPOSITES

Composites testing standards are of fundamental importance to the industry for several reasons:

Quality and Safety: Standards provide standards for testing, enabling producers and researchers to assess the quality and safety of composites. Compliance with regulatory requirements means that the composite material is compliant and safe for use in specific applications.

Comparability: Standards create a common reference framework for testing, allowing test results to be compared between different laboratories and research institutions. This ensures data consistency and trustworthiness.

Innovation and Development: Standardized testing methods support innovation and development of new composite materials.

Certification: Many industries such as aerospace, automotive or energy require composite materials to meet certain standards. Certification according to these standards is often necessary for the product to be placed on the market.

Legal Requirements: Some standards are set by law and compliance with them is mandatory. It is a guarantee that the products comply with legal regulations and are safe for consumers.

Overall, composite testing standards are a key tool for ensuring the quality, safety and comparability of composite materials in industry.

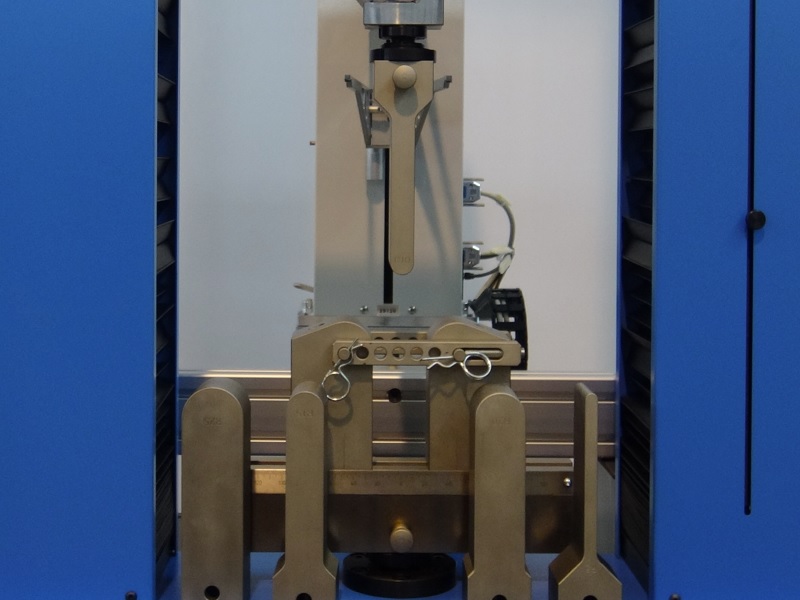

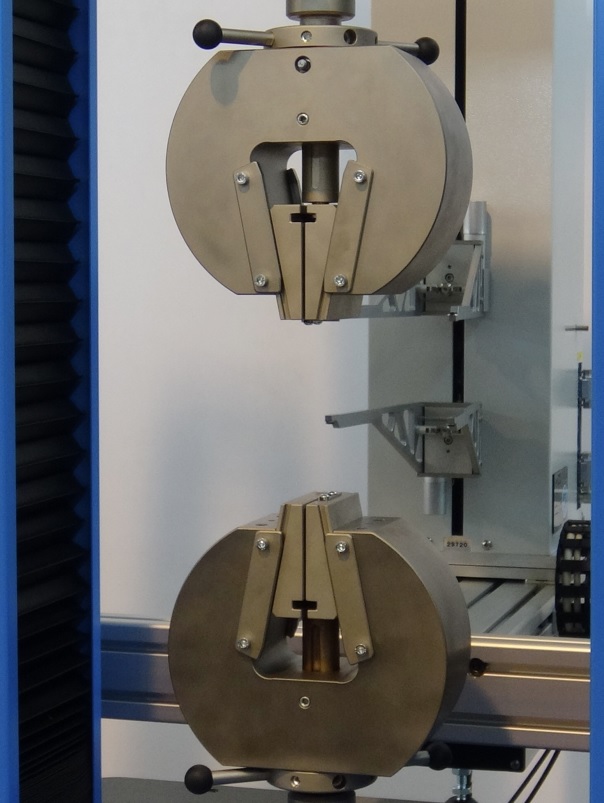

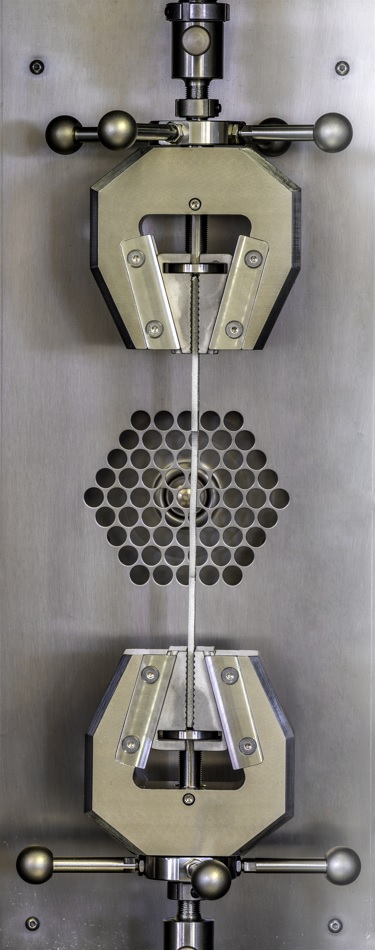

TENSILE TEST OF COMPOSITES

Tensile tests of composites, especially fiber-reinforced plastics, are key to assessing their mechanical properties. During these tests, elastic characteristics such as tensile modulus and Poisson’s ratio are determined, as well as tensile strength in the main material directions.

The tensile modulus indicates how the material reacts to a tensile load and measures its stiffness. Poisson’s ratio then characterizes the material in terms of its compressibility and extensibility under tensile load.

Tensile strength is another important property that indicates the maximum load that a material can withstand before it permanently deforms or fails.

This information is crucial for the design and manufacture of composite materials in all industries where they are used. Tensile testing provides important data that allows engineers and manufacturers to optimize the design and material composition of composite products, resulting in products with improved mechanical properties and increased reliability.

APPLICABLE STANDARDS FOR TENSILE TESTING OF COMPOSITES

The correct choice of standard is essential to ensure consistent and reliable results…

ČSN EN ISO 527-4

Plasty – Stanovení tahových vlastností – Část 4: Zkušební podmínky pro izotropní a orthotropní plastové kompozity vyztužené vlákny. Více informací …

| VÝBĚR STROJE |

ČSN EN ISO 527-5

Plasty – Stanovení tahových vlastností – Část 5: Zkušební podmínky pro plastové kompozity vyztužené jednosměrnými vlákny. Více informací …

| VÝBĚR STROJE |

ČSN EN 2561

Letectví a kosmonautika – Plasty vyztužené uhlíkovými vlákny – Jednosměrné kompozity – Zkouška tahem rovnoběžně se směrem vláken. Více informací …

| VÝBĚR STROJE |

ASTM D5766

Standardní zkušební metoda pro pevnost v tahu s otevřenými otvory kompozitních laminátů s polymerní matricí. Více informací …

| VÝBĚR STROJE |

ČSN EN 2597

Letectví a kosmonautika – Plasty vyztužené uhlíkovými vlákny – Jednosměrné kompozity – Zkouška tahem kolmo na směr vláken. Více informací …

| VÝBĚR STROJE |

ASTM D3039

Standardní zkušební metoda pro tahové vlastnosti kompozitních materiálů s polymerní matricí. Více informací …

| VÝBĚR STROJE |

Recommended testing machines designed for tensile testing of composites

We will be happy to advise you on the right choice of machine…

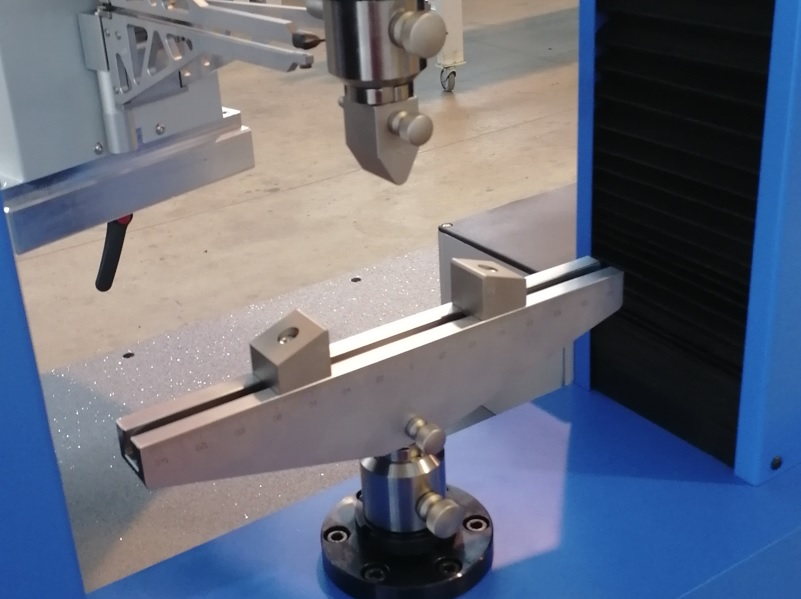

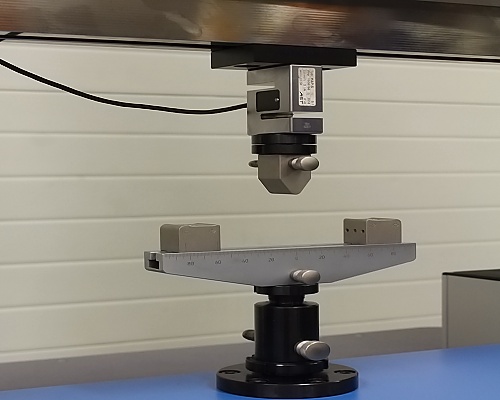

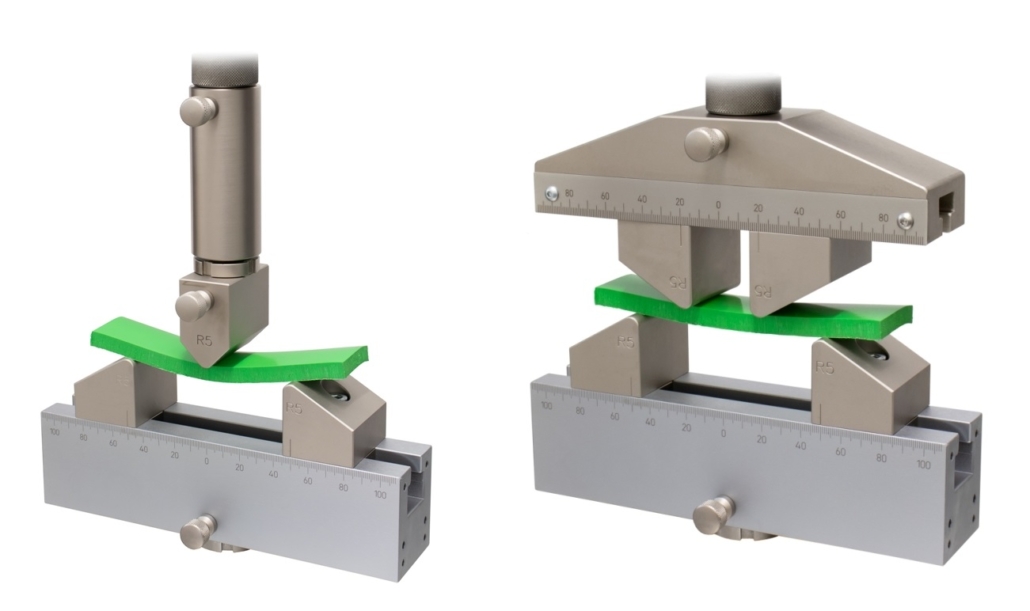

BENDING TEST OF COMPOSITES

Bending tests of composites are a key test for assessing their mechanical properties. There are two main types of bending tests: 3-point and 4-point, which allow the measurement of a material’s resistance to bending stress under different loading conditions.

Standards such as ČSN EN ISO 14125, ČSN EN ISO 2746, ASTM D 790 and ASTM D6272 provide standardized procedures for performing bending tests of composites. These standards specify parameters such as the geometry of the test specimens, the rate of loading and the way the results are evaluated, ensuring consistent and comparable results between different laboratories.

Due to the relatively simple test setup and execution, bending tests of composites are often used to ensure the quality of materials or to quickly compare their mechanical properties. These tests provide important information about the stiffness, strength and deformation behavior of composites, which is crucial for the design and production of composite products in various industries.

Bending testing of composites is a key tool for the design and manufacture of composite materials and products. The information obtained about mechanical properties allows engineers and manufacturers to optimize materials for specific applications. This test plays a role in the development of new materials, controls quality in the manufacturing process and ensures that the resulting products are durable, reliable and safe in real-world use.

APPLICABLE STANDARDS FOR BENDING TESTS OF COMPOSITES

The correct choice of standard is essential to ensure consistent and reliable results…

ČSN EN 2746

Letectví a kosmonautika – Sklem vyztužené plasty – Zkouška ohybem – Metoda tříbodového ohybu. Více informací…

| VÝBĚR STROJE |

ASTM D7264

Standardní zkušební metoda pro ohybové vlastnosti kompozitních materiálů s polymerní matricí. Více informací…

| VÝBĚR STROJE |

ČSN EN 2562

Letectví a kosmonautika – Plasty vyztužené uhlíkovými vlákny – Jednosměrné kompozity – Zkouška ohybem ve směru vláken. Více informací…

| VÝBĚR STROJE |

ASTM D6272

Standardní zkušební metoda pro ohybové vlastnosti nevyztužených a vyztužených plastů a elektroizolačních materiálů čtyřbodovým ohýbáním. Více informací…

| VÝBĚR STROJE |

ASTM D790

Standardní zkušební metody pro ohybové vlastnosti nevyztužených a vyztužených plastů a elektroizolačních materiálů. Více informací…

| VÝBĚR STROJE |

ČSN EN ISO 14125

Recommended testing machines designed for flexural testing of composites

We will be happy to advise you on the right choice of machine…

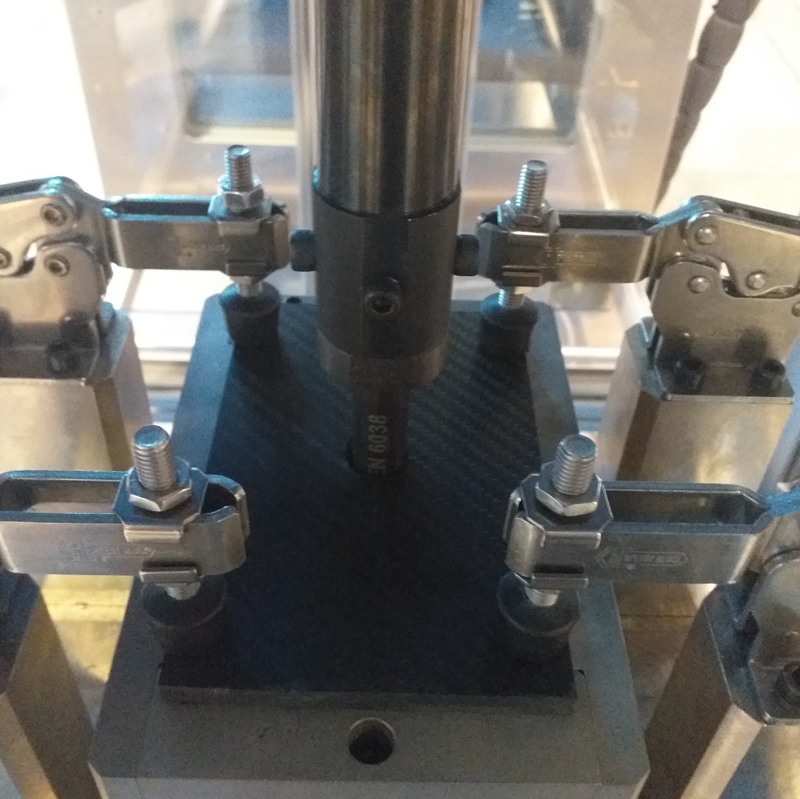

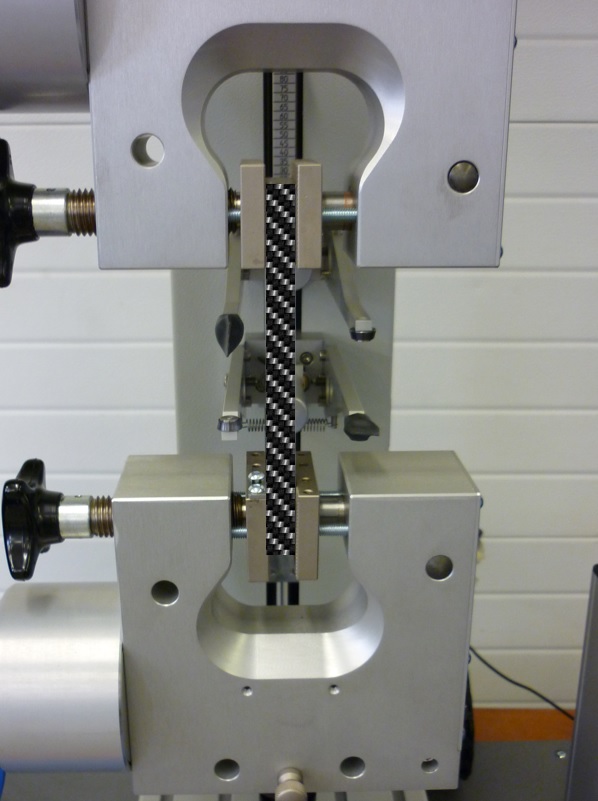

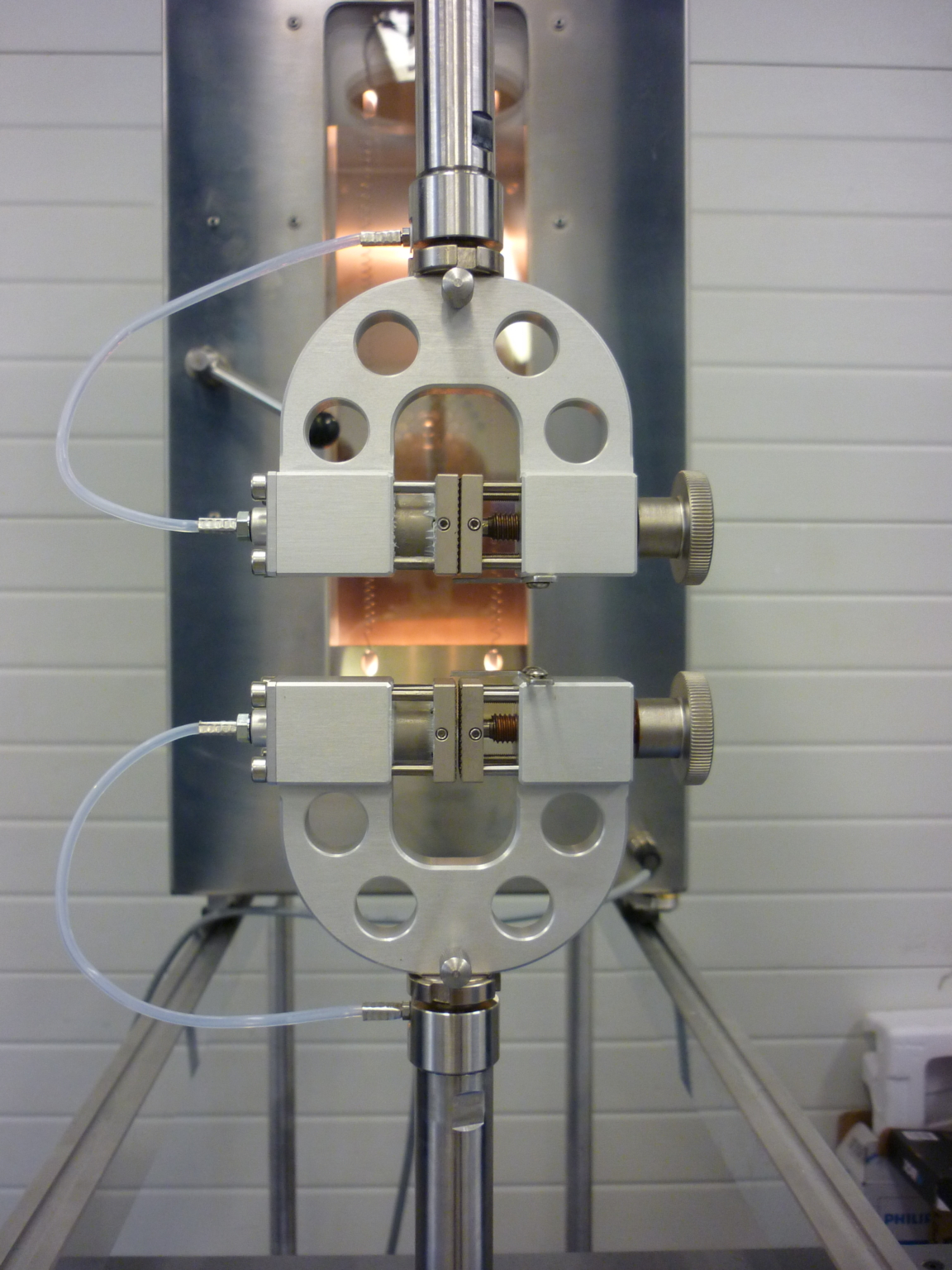

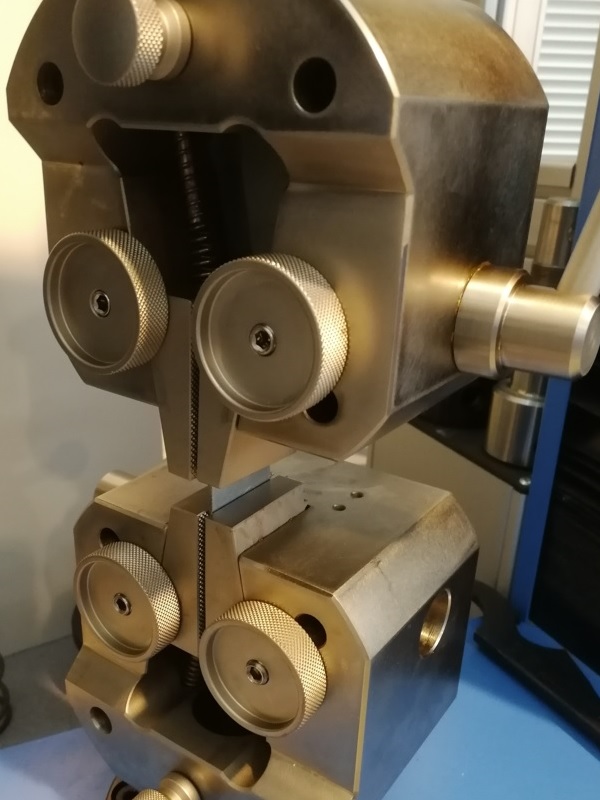

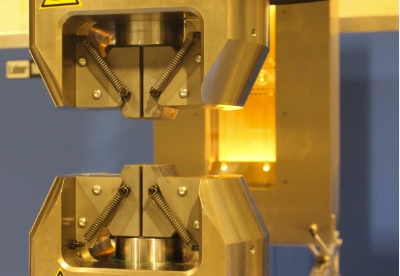

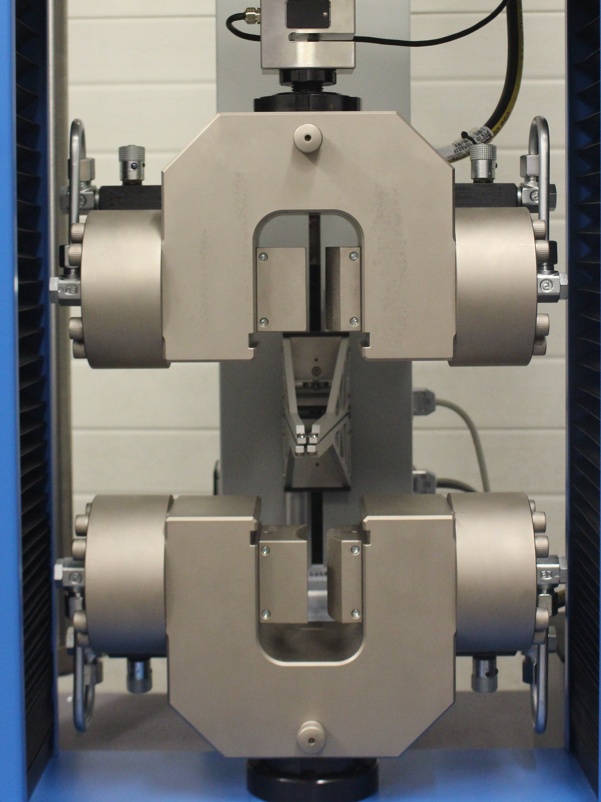

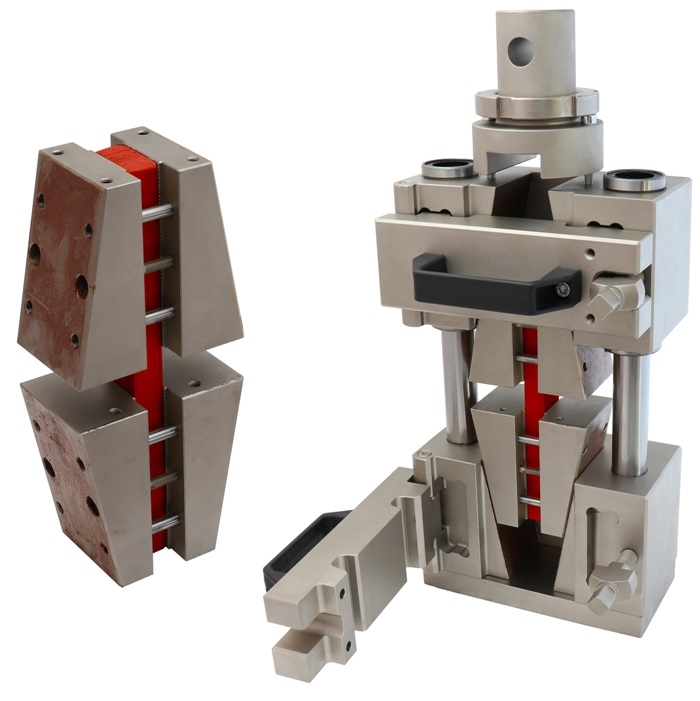

PRESSURE TEST OF COMPOSITES

Compressive testing of composites, especially fiber-reinforced plastics, is key to understanding their behavior under various loads. In these tests, we focus on two main parameters: compressive modulus and compressive strength in the main material directions.

The compressive modulus indicates the material stiffness in the compressive direction, which is important for understanding how the composite behaves under compressive loading. Compressive strength then measures the maximum compressive force that the material can withstand before permanent failure.

There are several normative documents for performing these tests, such as ASTM D695, ASTM D3410, ASTM D6641 or ISO 14126. These standards provide standardized procedures and parameters for performing the tests, ensuring consistency and comparability of results between different laboratories.

APPLICABLE STANDARDS FOR PRESSURE TESTING OF COMPOSITES

Standards for compressive testing of composites are key to the aerospace, energy and automotive industries…

ČSN EN 2850

Letectví a kosmonautika – Jednosměrné lamináty s termosetovou pryskyřicí a uhlíkovými vlákny – Tlaková zkouška rovnoběžně se směrem vláken. Více informací …

| VÝBĚR STROJE |

ČSN EN ISO 14126

Vlákny vyztužené plastové kompozity – Stanovení vlastností v tlaku v rovině výztuže. Více informací …

| VÝBĚR STROJE |

ASTM D6641

Standardní zkušební metoda pro kompresní vlastnosti kompozitních materiálů s polymerní matricí pomocí kombinovaného nakládacího kompresního přípravku (CLC) zkušebního přípravku. Více informací …

| VÝBĚR STROJE |

ASTM D695

Airbus AITM1-0008-A

ASTM D6742

Standardní postup pro zkoušení tahem a tlakem s vyplněnými dírami u kompozitních laminátů s polymerní matricí. Více informací …

| VÝBĚR STROJE |

Boeing BSS 7260

BOEING BSS 7260 se používá pro testování kompozitních materiálů při jednoosé kompresi.. Více informací …

| VÝBĚR STROJE |

ASTM D6484

Standardní zkušební metoda pro pevnost v tlaku u kompozitních laminátů s polymerní matricí s otevřenými otvory. Více informací …

| VÝBĚR STROJE |

ASTM D3410

Standardní zkušební metoda pro tlakové vlastnosti kompozitních materiálů s polymerní matricí s nepodporovaným průřezem kalibrem smykovým zatížením . Více informací …

| VÝBĚR STROJE |

Recommended testing machines designed for pressure testing of composites

We will be happy to advise you on the right choice of machine…

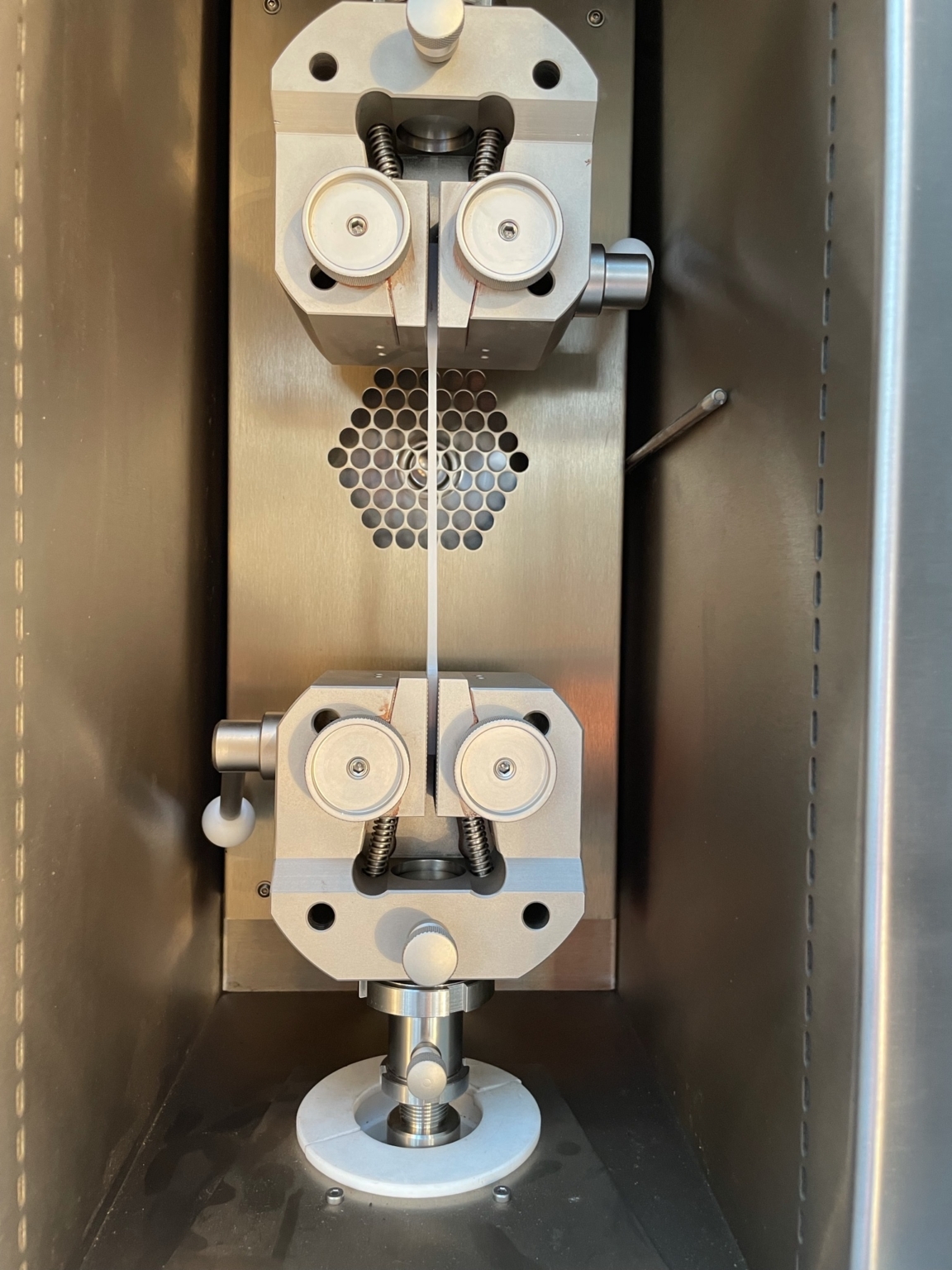

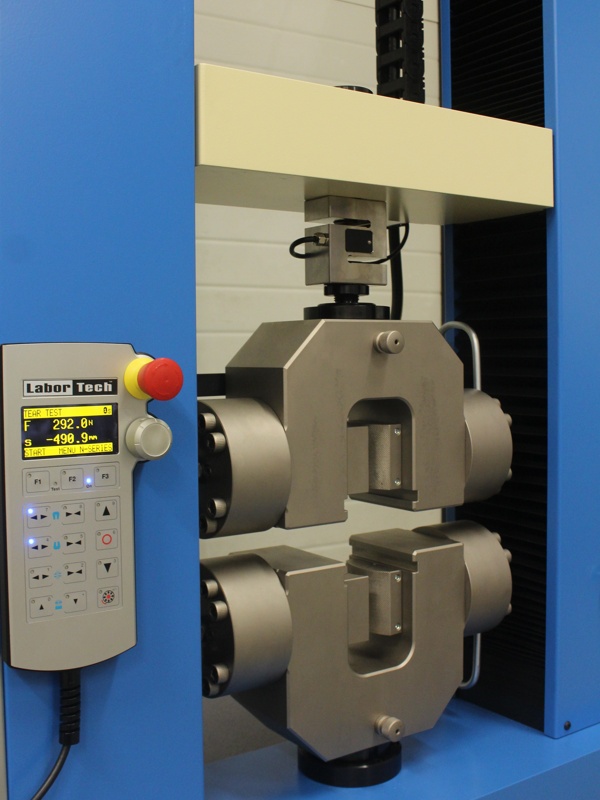

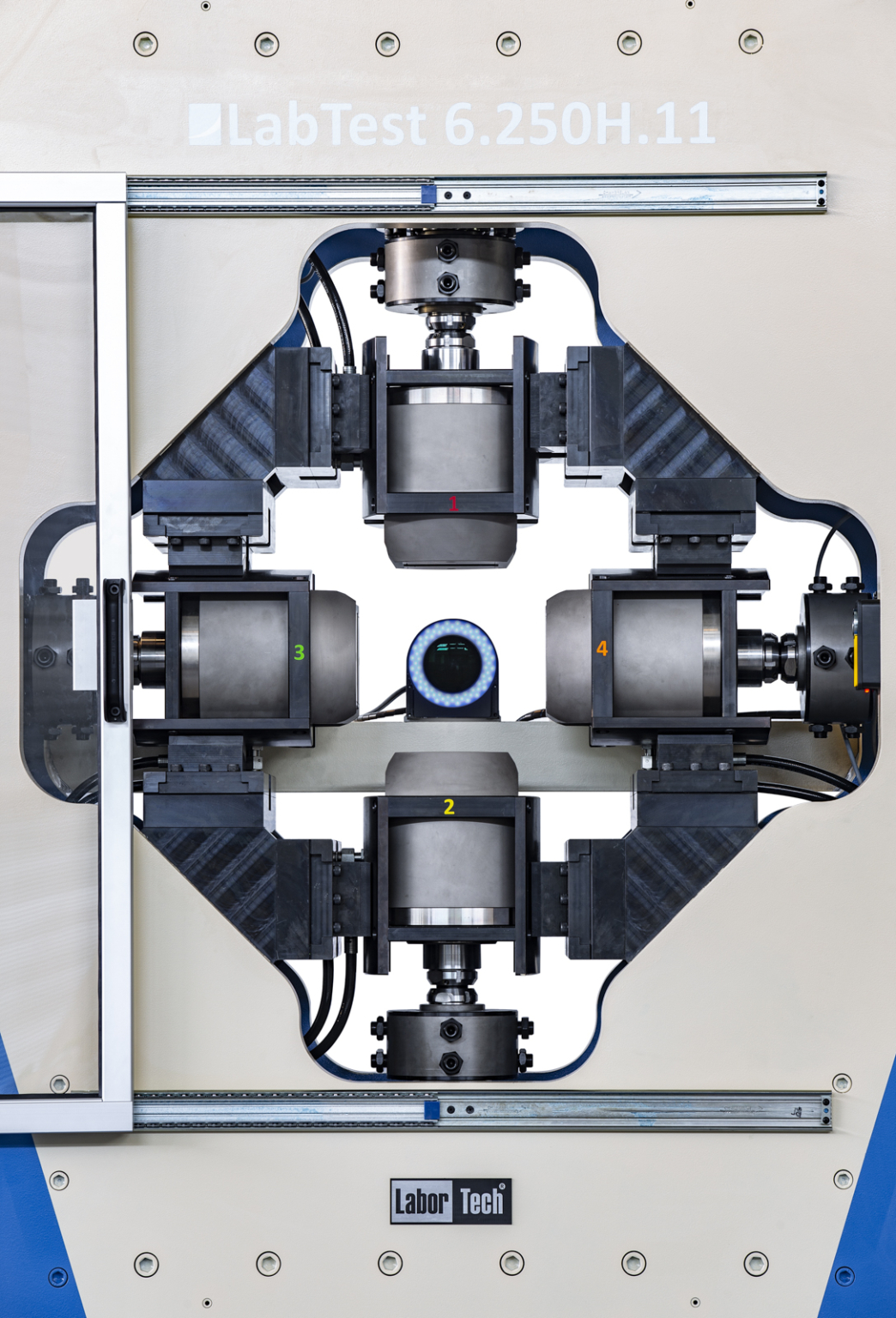

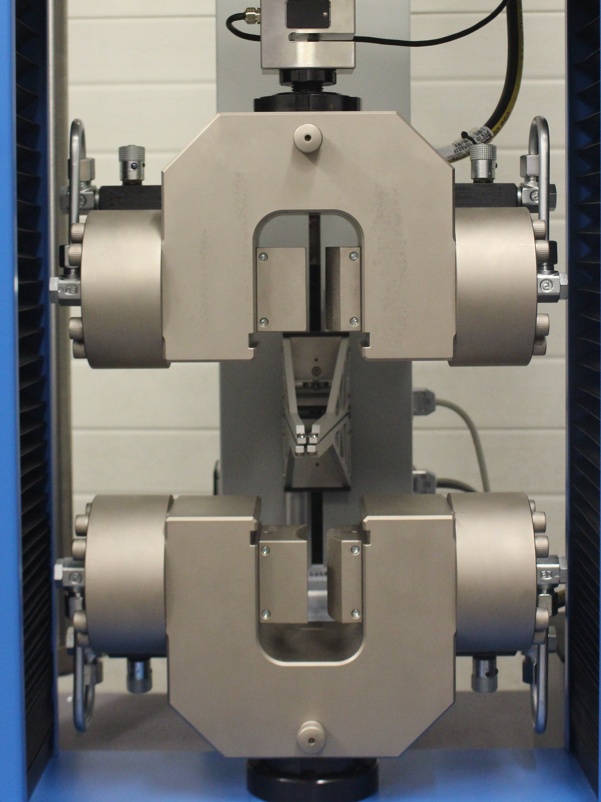

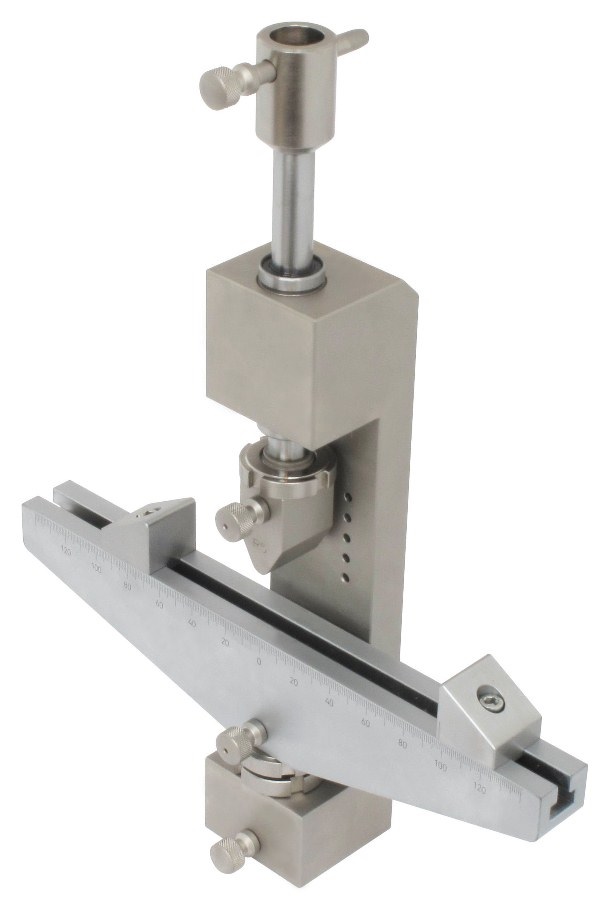

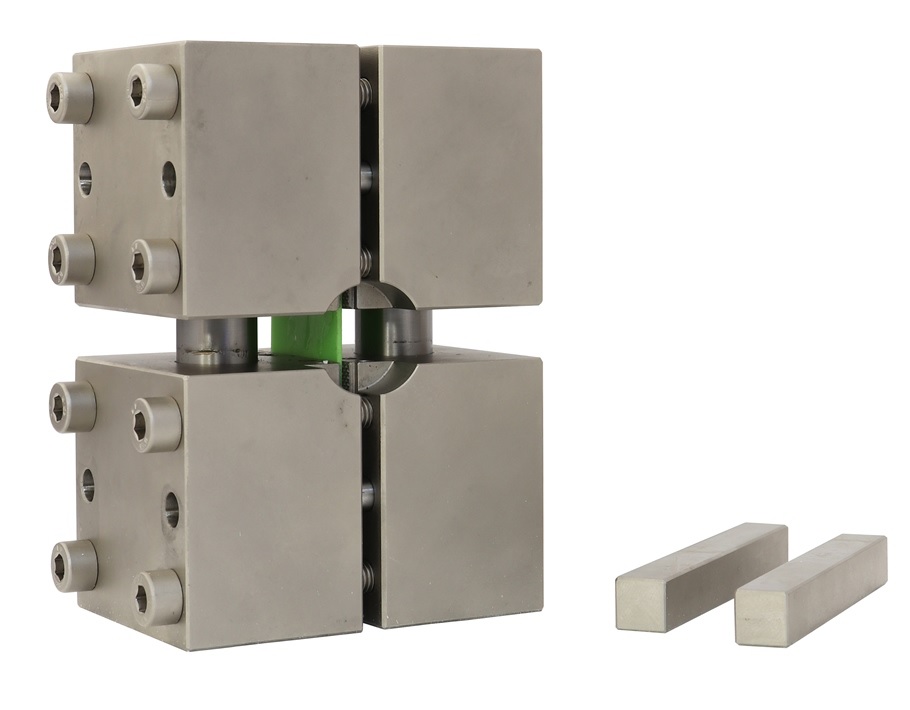

SHEAR TESTS OF COMPOSITES

Shear tests of composites represent a key test for assessing their mechanical properties, especially resistance to shear stress and deformation. During this test, the material is subjected to a force that acts uniformly horizontally, causing the material to shift relative to itself.

The main goal of shear tests is to obtain data on the strength of the composite material against shear stress, its shear modulus and other parameters that are key to the design and production of composite products.

There are several normative documents for performing these tests, such as ASTM 5379, ASTM D7078, ASTM D3518 or ISO 14129. These standards provide standardized procedures and parameters for performing the tests, ensuring consistency and comparability of results between different laboratories.

In addition, special tests are also used in the aerospace industry, such as compression tests according to Airbus AITM1-0002 standards, which allow a thorough evaluation of the behavior of composites under different loading conditions. These tests are key to ensuring the safety and reliability of composite materials in complex applications such as the aerospace industry.

These norms and standards are key to ensuring consistency and comparability of composite shear test results across different laboratories and research institutions. They provide reliable methods for evaluating the mechanical properties of composites and are an important tool for engineers in the aerospace, energy or automotive industries.

APPLICABLE STANDARDS FOR SHEAR TESTS OF COMPOSITES

Composite shear test standards are key to the aerospace, energy and automotive industries…

ČSN EN ISO 14129

Vlákny vyztužené plastové kompozity – Tahová zkouška na ±45° laminátech pro stanovení křivky smykové napětí / smyková deformace, smykového modulu a smykové pevnosti v rovině . Více informací…

| VÝBĚR STROJE |

ASTM D3518

Standardní zkušební metoda pro odezvu na smyk v rovině kompozitních materiálů s polymerní matricí zkouškou tahem ±45° laminátu . Více informací…

| VÝBĚR STROJE |

Airbus AITM1-0002

Plasty vyztužené vlákny – Stanovení vlastností ve smyku v rovině (±45° zkouška tahem)

| VÝBĚR STROJE |

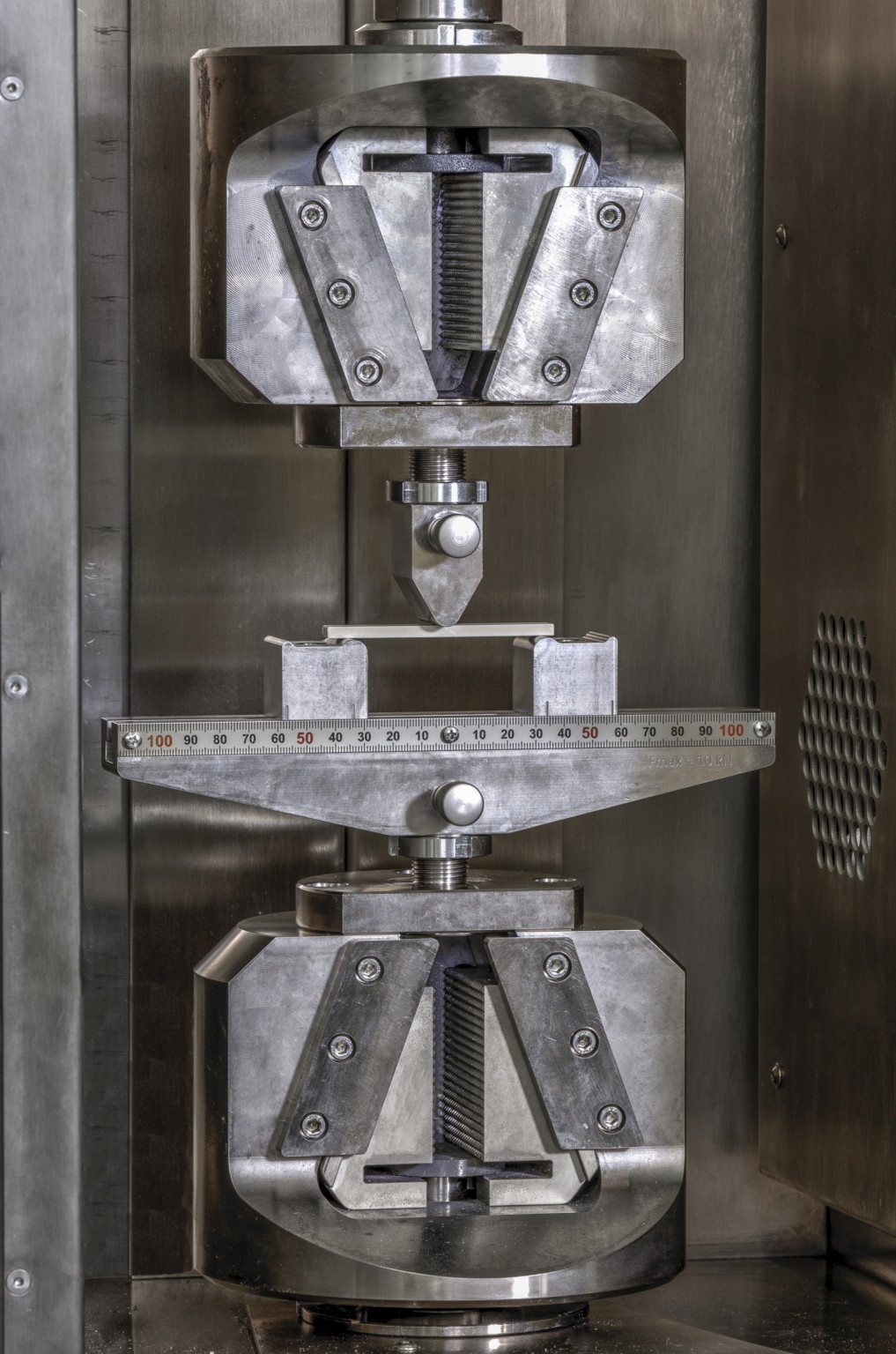

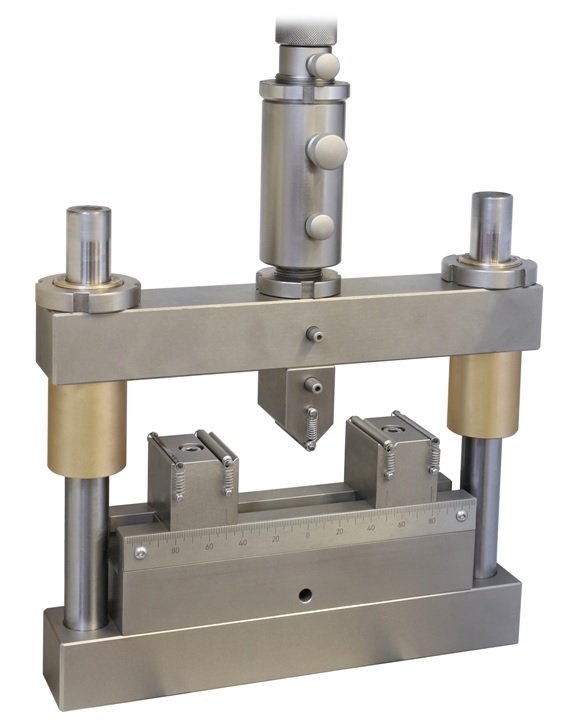

ASTM D5379

Standardní zkušební metoda pro smykové vlastnosti kompozitních materiálů metodou V-Notched Beam. Více informací…

| VÝBĚR STROJE |

ASTM D7078

Standardní zkušební metoda pro smykové vlastnosti kompozitních materiálů metodou V-vrubového smyku. Více informací…

| VÝBĚR STROJE |

Recommended testing machines designed for shear tests of composites

We will be happy to advise you on the right choice of machine…

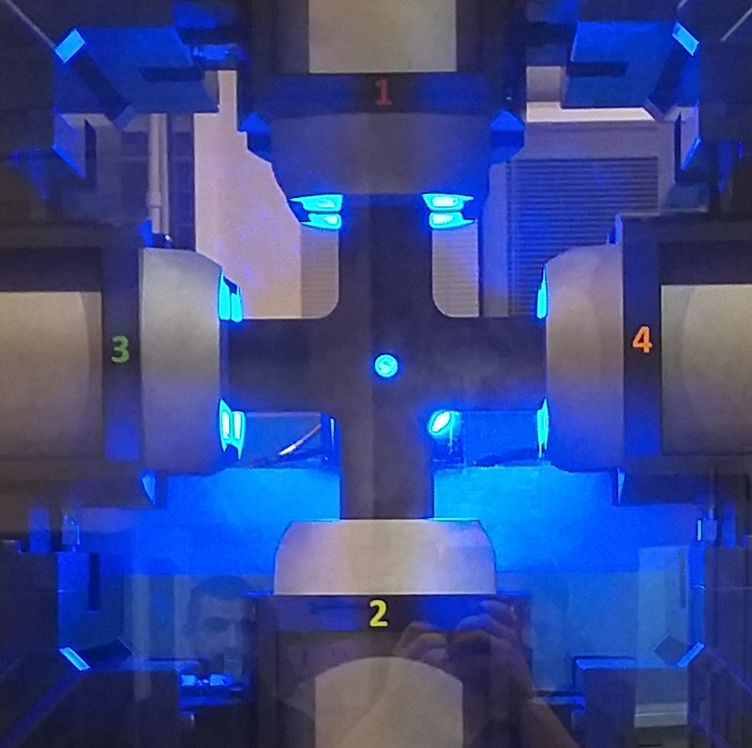

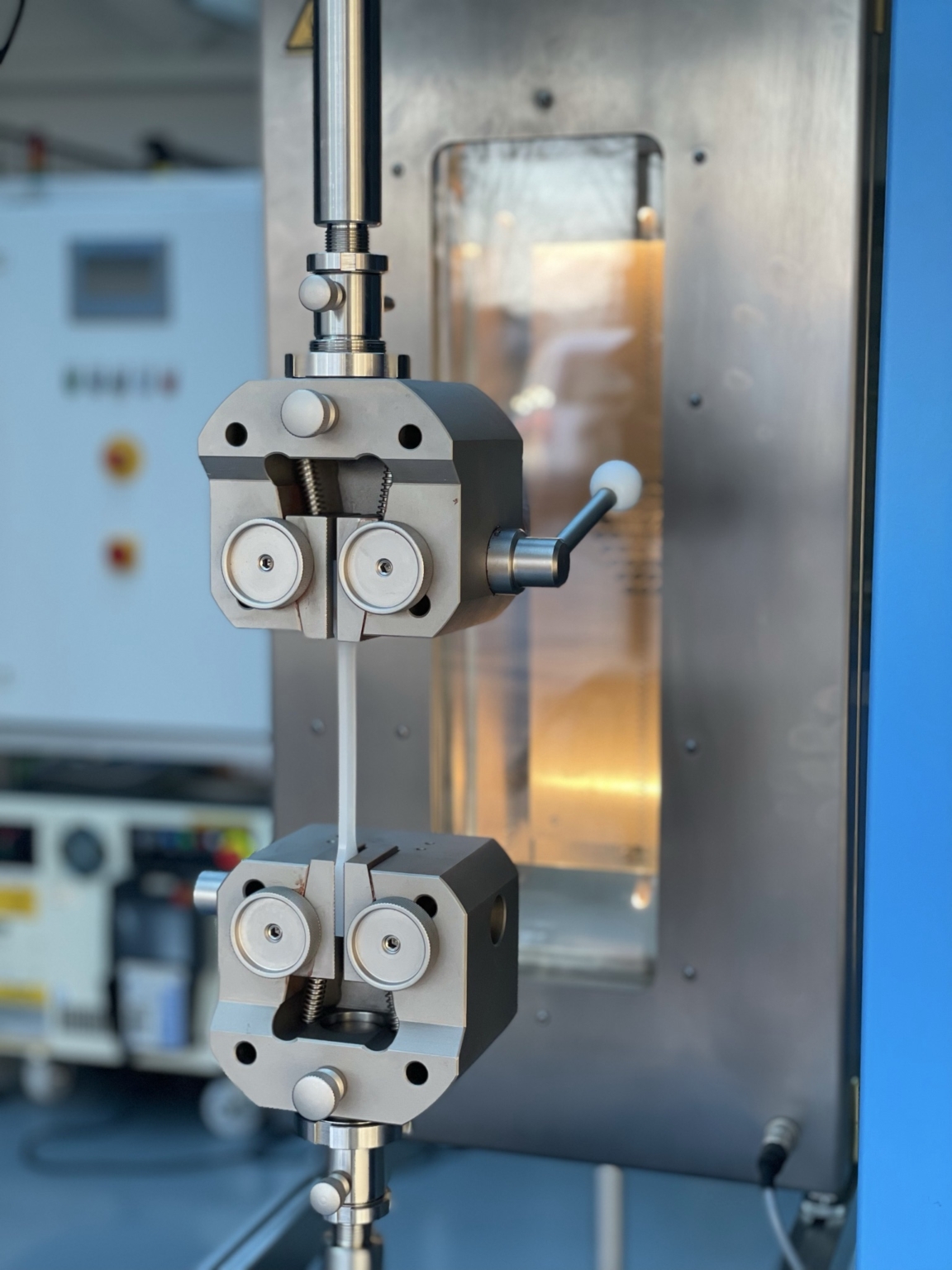

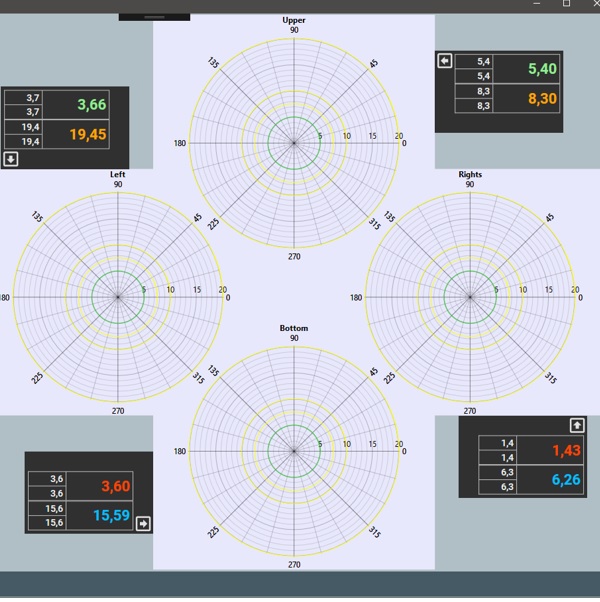

CYCLIC FATIGUE TEST ON COMPOSITES

Dynamic cyclic testing of composite materials plays a key role in evaluating their fatigue behavior and deriving the Wöhler curve, which is important for predicting the durability and reliability of materials under repeated loading.

Standardized standards such as ASTM D3479 and ISO 13003 provide precise procedures for performing dynamic cyclic testing of composite materials. These standards specify the parameters of the tests, including the frequency of loading, the amplitude of loading and the geometry of the test specimens, as well as the method of evaluating the results.

During these tests, the composite material is subjected to repeated cyclic bending loads, while its response is monitored over time. In this way, important information can be obtained about the fatigue behavior of the material and its service life under specific load conditions can be determined.

Dynamic cyclic testing of composites is therefore an essential tool for engineers and manufacturers involved in the development and production of composite materials for various industrial applications. These tests help ensure that the composite materials meet the requirements for durability and reliability in real-world use.

To investigate repeated cyclic loading of composites, special test methods and equipment are used to simulate different stress conditions. These tests are important for the development and evaluation of composite materials, especially where high resistance to repeated stress is required, such as in aircraft and automotive construction and in the energy industry.

APPLICABLE STANDARDS FOR CYCLIC FATIGUE TESTS ON COMPOSITES

The correct choice of standard is essential to ensure consistent and reliable results…

ASTM D6115

Standardní zkušební metoda pro únavovou delaminaci módu I Začátek růstu jednosměrných kompozitů s polymerní matricí vyztužených vlákny. Více informací…

| VÝBĚR STROJE VÝBĚR STROJE |

ASTM D3479

Standardní zkušební metoda pro tahovou a tahovou únavu kompozitních materiálů s polymerní matricí. Více informací…

| VÝBĚR STROJE VÝBĚR STROJE |

ASTM D6873

Standardní postup pro odezvu na únavu ložisek kompozitních laminátů s polymerní matricí. Více informací…

| VÝBĚR STROJE VÝBĚR STROJE |

Airbus AITM1-0075

Standardní zkušební metoda pro tahovou a tahovou únavu kompozitních materiálů .

| VÝBĚR STROJE VÝBĚR STROJE |

ASTM D7615

Standardní postup pro reakci na únavu otevřených otvorů kompozitních laminátů s polymerní matricí. Více informací…

| VÝBĚR STROJE VÝBĚR STROJE |

ISO 13003

Plasty vyztužené vlákny. Stanovení únavových vlastností za podmínek cyklického zatížení. Více informací…

| VÝBĚR STROJE VÝBĚR STROJE |

Recommended testing machines designed for cyclic fatigue tests on composites

We will be happy to advise you on the right choice of machine…

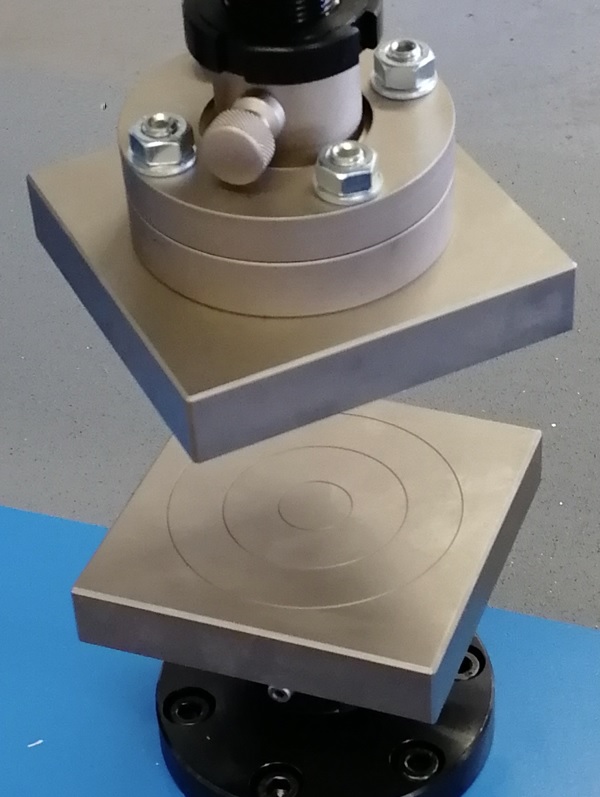

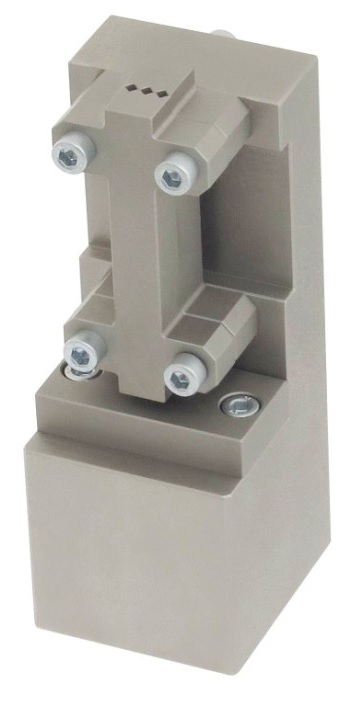

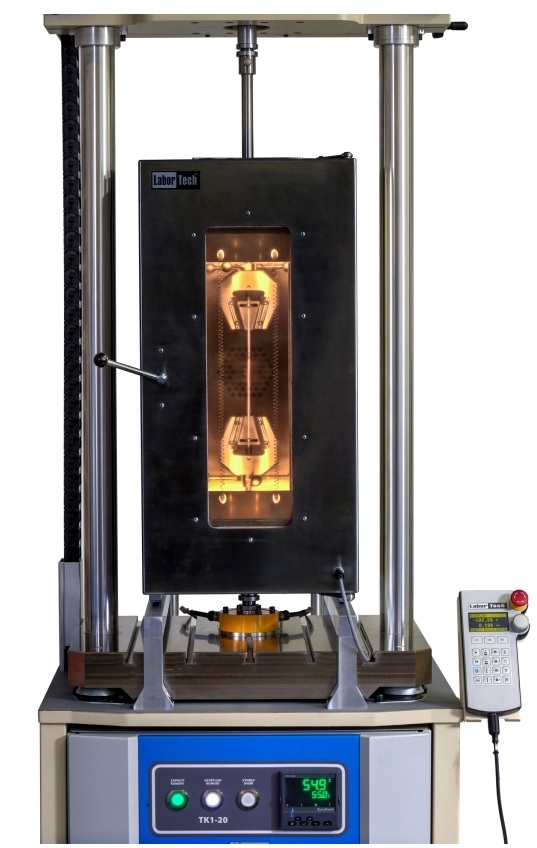

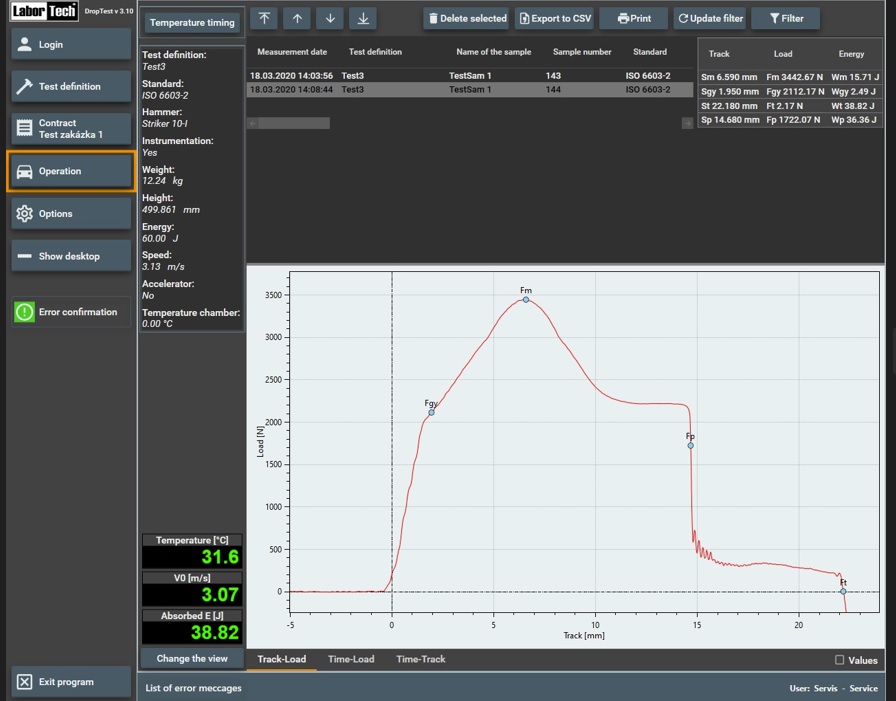

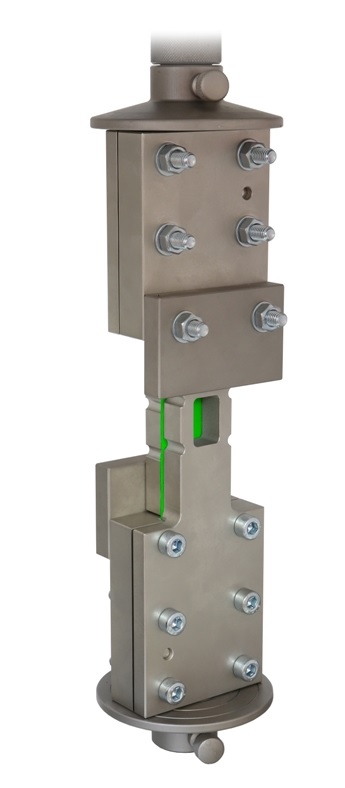

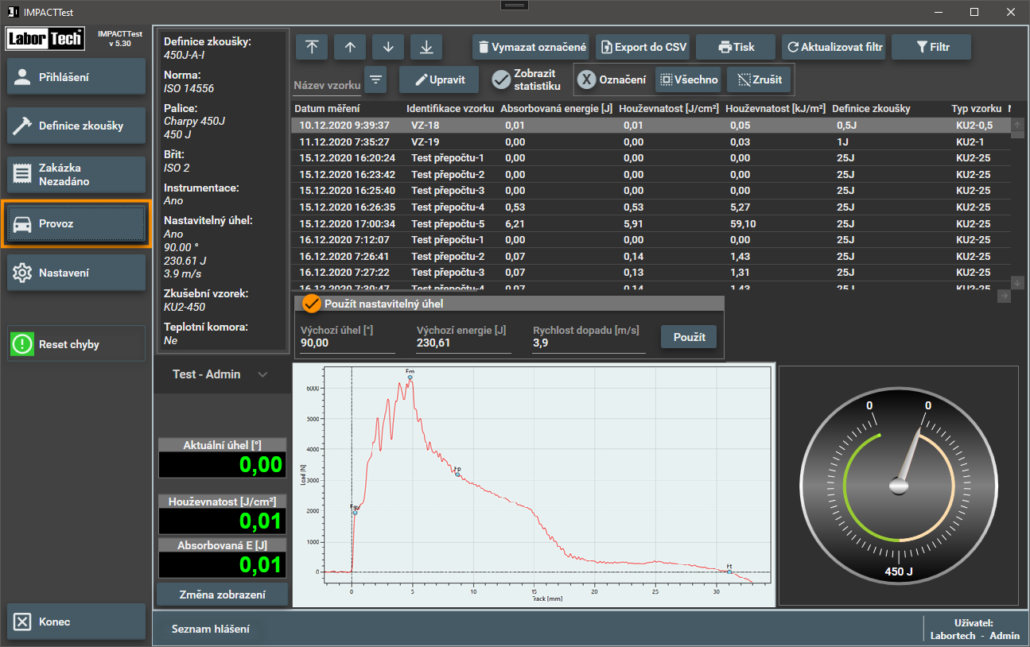

IMPACT TESTS ON COMPOSITES

Impact testing of composite materials represents an important testing procedure for assessing their behavior under various loading conditions. During these tests, the composite material is subjected to rapid and short-term loading that simulates sudden shocks or impacts that may occur in real-world operating conditions.

The goal of impact tests is to determine the material’s resistance to sudden loads and to obtain information about its fracture behavior and absorption energy. This type of testing is particularly important in applications where composite materials are exposed to sudden mechanical impacts, such as the aerospace and automotive industries, sports equipment or ship construction.

Standards such as ASTM D7136 and ISO 6603 provide standardized procedures for performing impact tests on composite materials. During these tests, the energy absorbed by the material upon impact is measured and its deformation behavior is monitored.

Composite impact testing is a key tool for engineers and manufacturers who want to ensure that composite materials meet the highest quality and safety standards.

APPLICABLE STANDARDS FOR IMPACT TESTING OF COMPOSITES

By choosing the right test standard, you indicate the right direction of testing…

ASTM D7136

Standardní zkušební metoda pro měření odolnosti kompozitu polymerové matrice vyztuženého vlákny proti nárazu způsobenému pádem. Více informací…

| VÝBĚR STROJE |

ČSN EN ISO 6603-2

Plasty – Stanovení chování tuhých plastů při víceosém rázovém namáhání – Část 2: Instrumentovaná rázová zkouška. Více informací…

| VÝBĚR STROJE |

Recommended testing machines designed for impact tests of composites

We will be happy to advise you on the right choice of machine…

Contact

LABORTECH s.r.o. , Rolnická 1534/130a, 747 05 Opava, Czech Republic

Research & Development

Reducing energy intensity We increase your productivity Development and implementation

News & Events