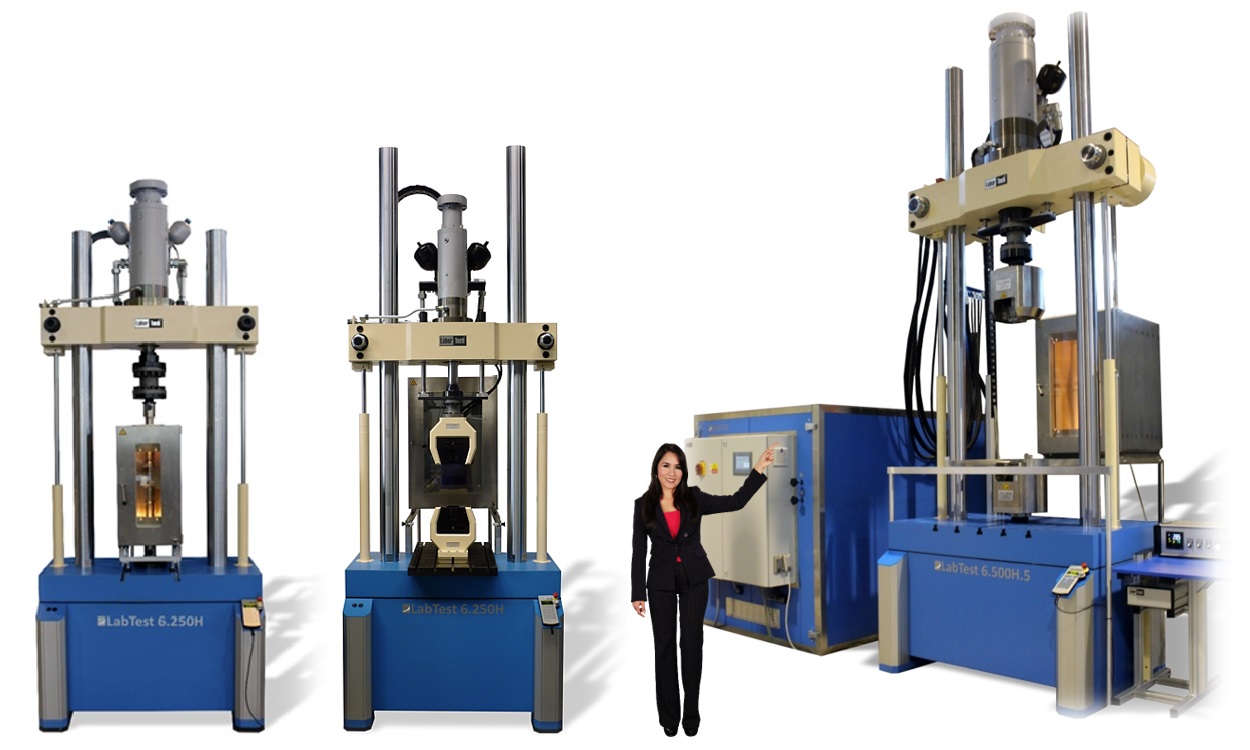

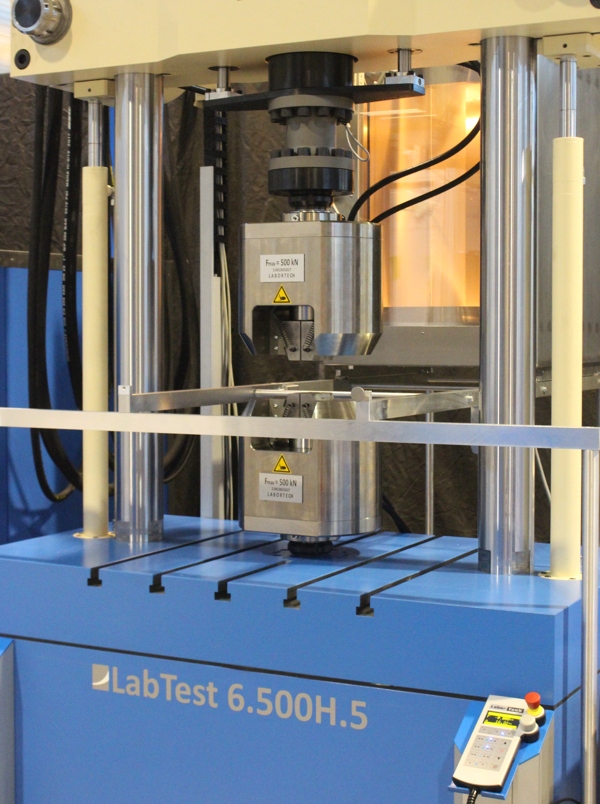

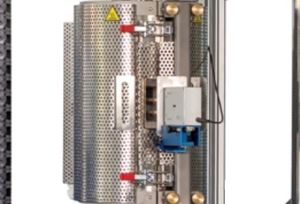

H. 5 – DYNAMIC HYDRAULIC TESTING MACHINES UP TO 2500 KN – 01 SERIES

Dynamic hydraulic testing machines of H. 5 type and series 01 in design up to 2500 kN with servo cylinder in the crossbar are designed for low and high cycle fatigue tests, fracture toughness, crack propagation, etc. This series of machines is characterized by high frame rigidity and mechanical resistance . The range of a given machine depends on the dynamic stroke and frequency. A specific test set is derived from these parameters, which consists of a test frame, a servo-hydraulic cylinder and a hydraulic unit.

Download:

Key features of the H.5 series 01 with a servo cylinder in the crossbar

MEZERA

MEZERA

- Stand design with high axial rigidity and mechanical resistance.

- Possibility of extending the test frame by automatic electro-hydraulic transfer and clamping of the crossbar.

- Guaranteed system alignment in accordance with ASTM E 1012.

- Integrated servo cylinder in the machine base for pressures of 210 or 280 bar.

- Test control by proportional or servo valve with the possibility of control in the power and position loop.

- Complete test evaluation and control is provided by Test & Motion material testing software – DYNPACK.

- Load cell in the upper crossbar working in the accuracy class according to EN ISO 7500-1, ASTM E4 with the possibility of linearization.

- Powerful compact hydraulic units of the HAD series with low noise level thanks to the PAC system.

- HALT 18 hydraulic unit diagnostics controlled by TOUCH LCD SIEMENS as standard.

- The H.5 series machines comply with all the above-mentioned EC directives on machinery and equipment and work in accordance with the new safety functions according to EN ISO 13850:2015

- The machine is controlled by measuring and control electronics of the EDCi series with a sampling frequency of 10 kHz. Analog signal resolution level ± 250,000 divisions (20 ms).

- Preparation for integration of measuring and setting unit BENTROD for evaluation and optimization of concentric and edge alignment correction according to ASTM E101.

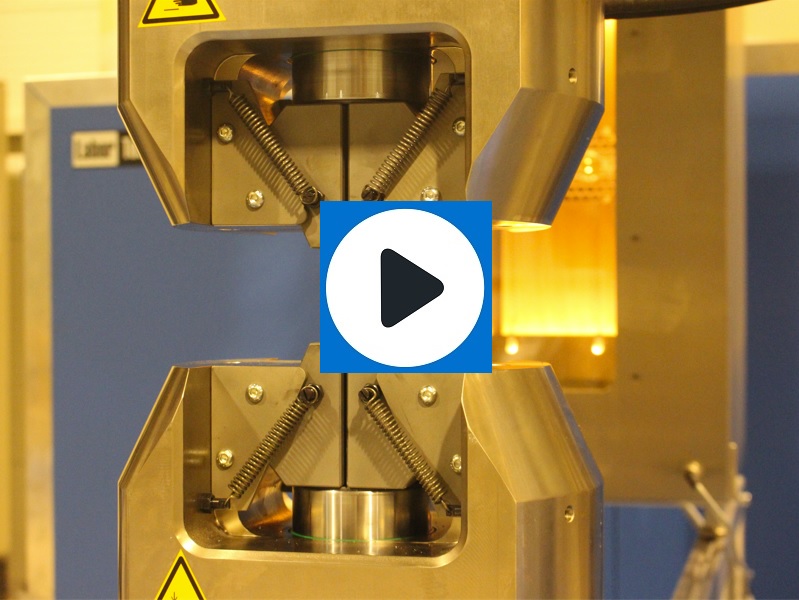

- Integration of hydraulic grips with wedge clamping or various jigs according to standards, etc.

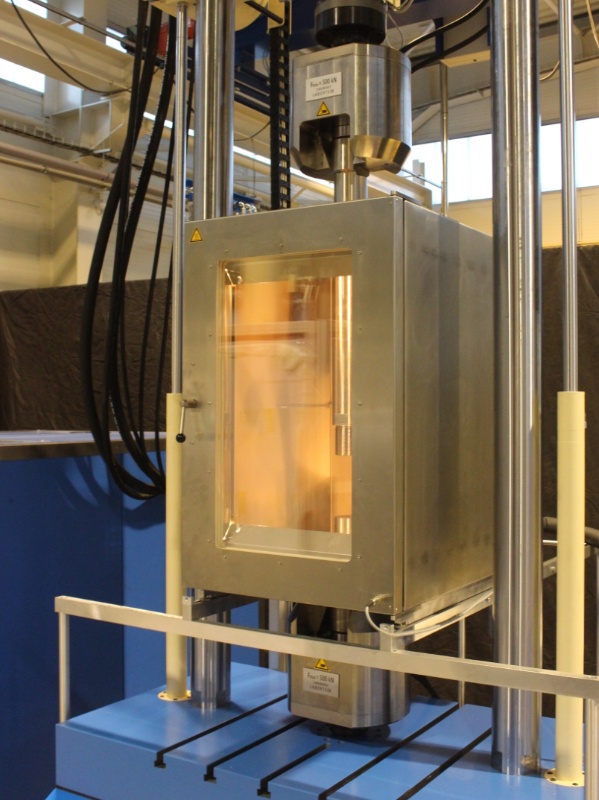

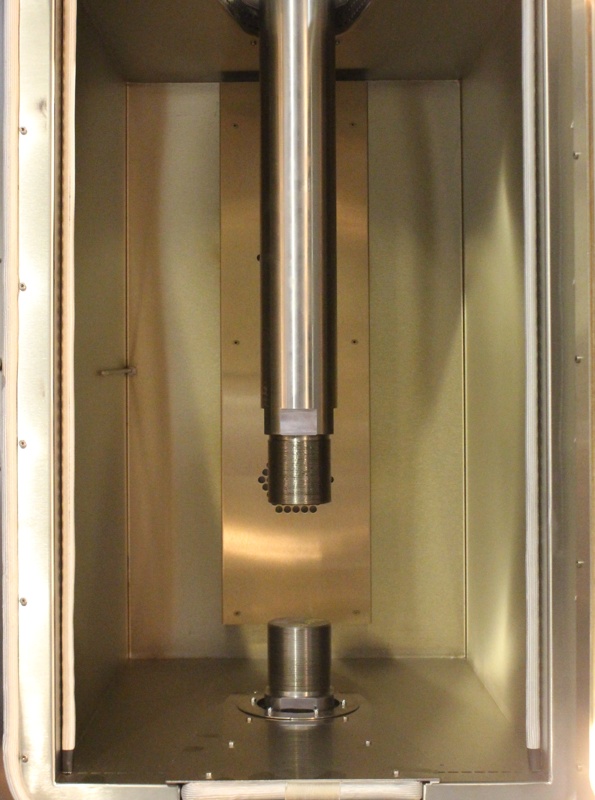

- High-precision tests with temperature chamber or high-temperature furnace.

MEZERA

VIDEOS on LabTest H.5 series testing machines

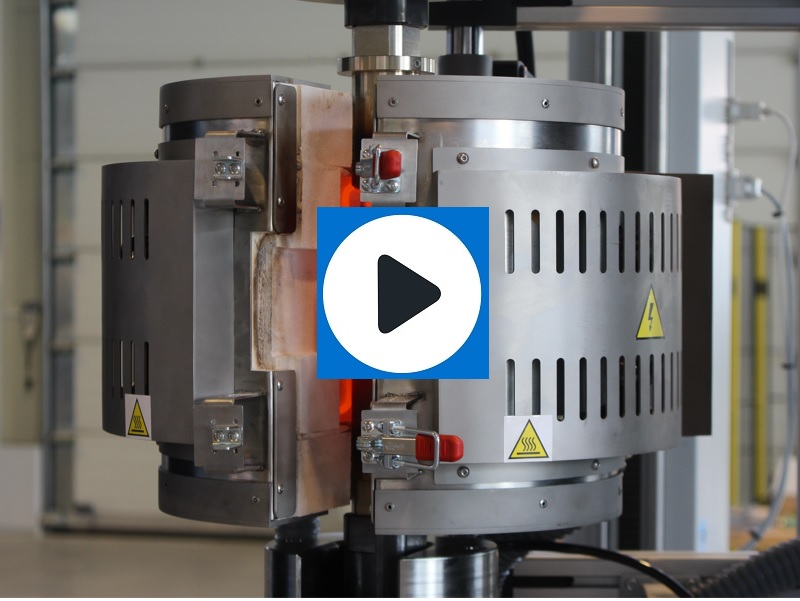

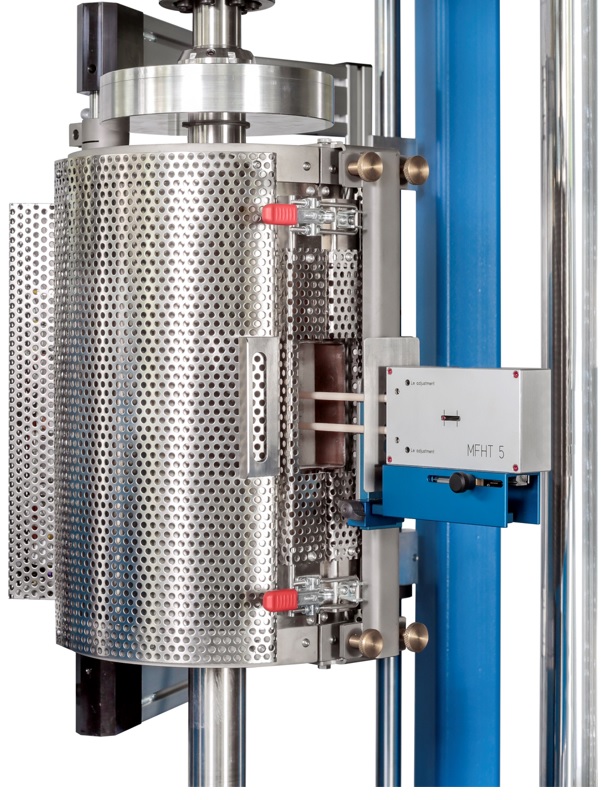

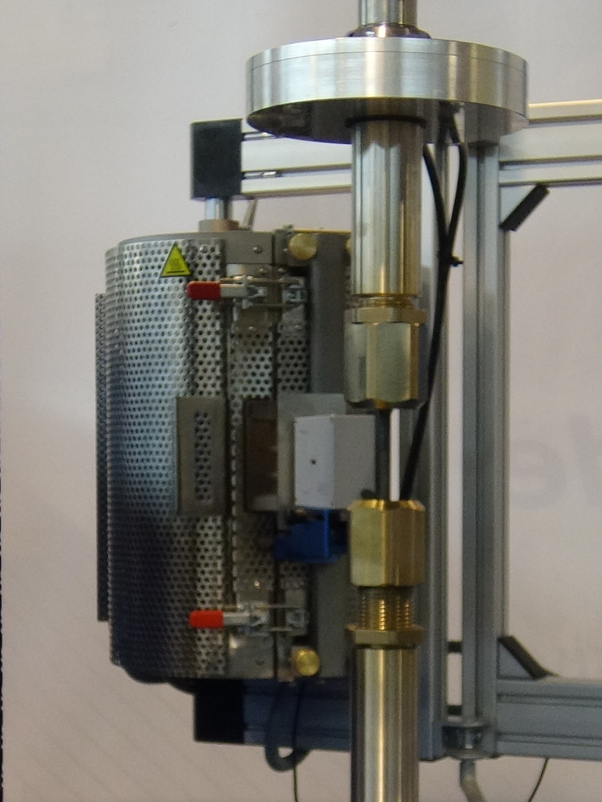

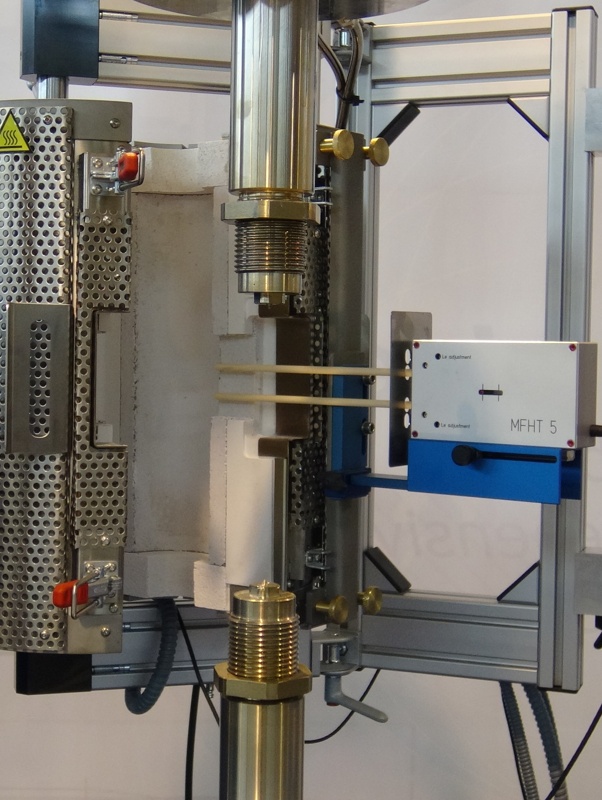

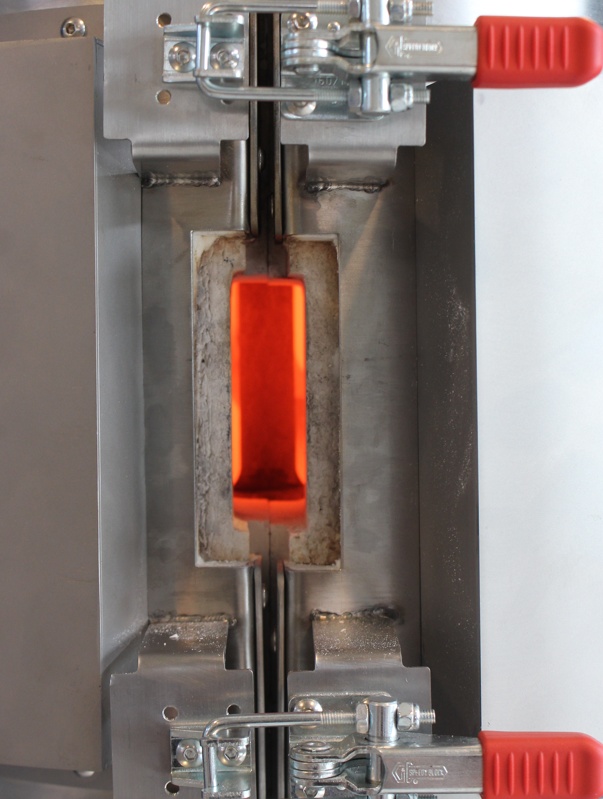

Installation of test fixtures in a high temperature chamber

Příprava příslušenství pro tahové zkoušky ve vysokoteplotní komoře do 1200°C dle normy EN ISO 6892-2 s bezkontaktním extenzometrem ONE.

Dynamic durability life test of load springs

LABORTECH H.5 series testing machines can be tested and assessed for conformity under GMW 14656. This standard describes GM’s requirements for materials, manufacturing process and coatings used in the manufacture of automotive springs and leaf springs.

Dynamic test of shock absorbers for railways

Dynamic testing of shock absorbers in different dynamic cycles with different testing amplitudes guarantees 100% testing of the shock absorber function.

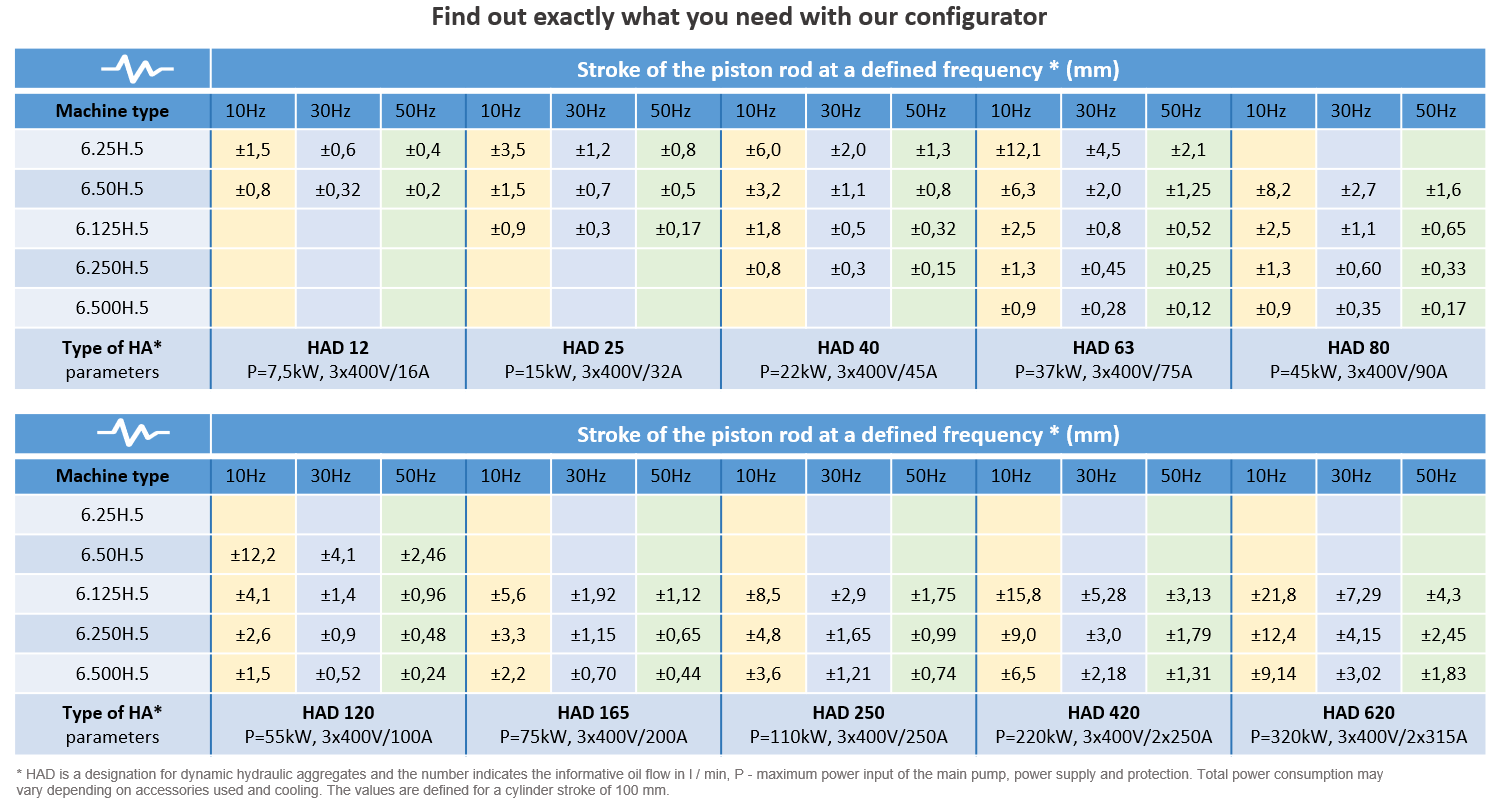

Find out the parameters of your own dynamic test set!

MEZERA

All HAD hydraulic units we offer have a low noise level.

MEZERA

Do you have questions about our products?

Feel free to contact our product experts.

We look forward to your interest.

–

MEZERA

TESTING ON LABTEST H.5 MACHINES WITH VARIOUS ACCESSORIES

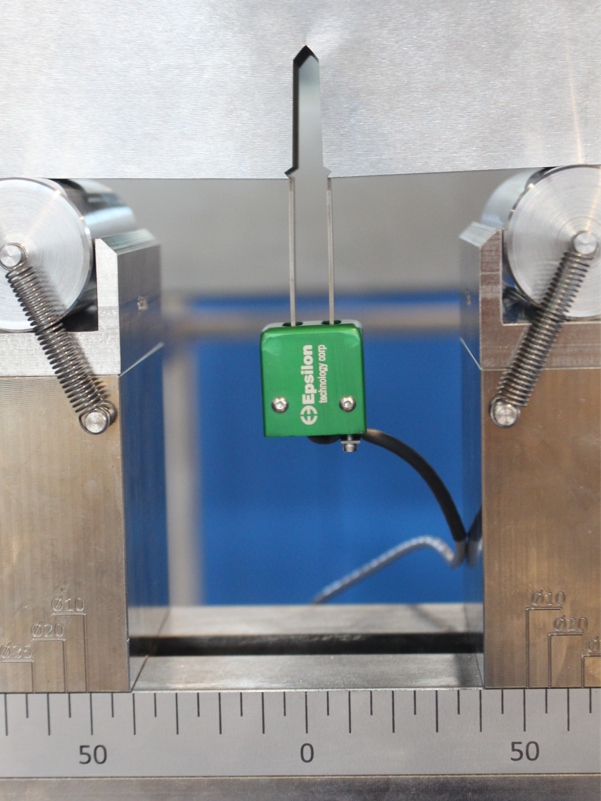

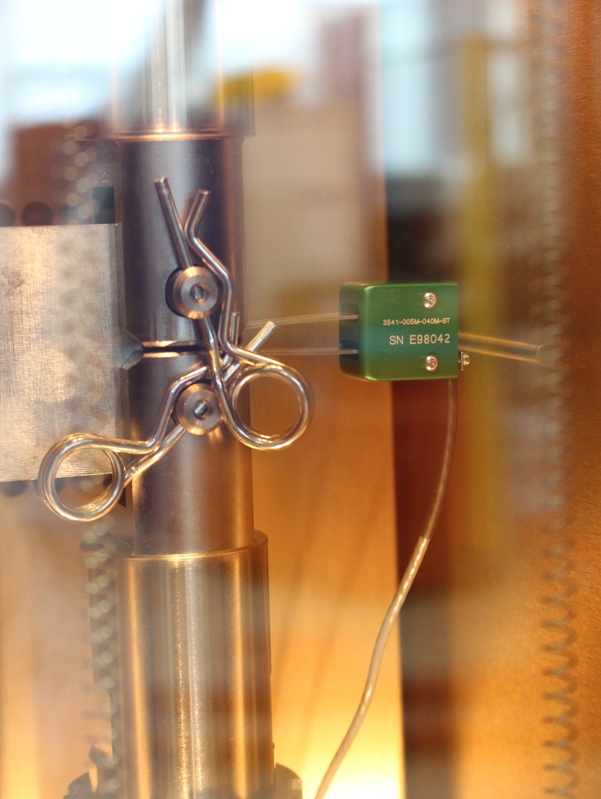

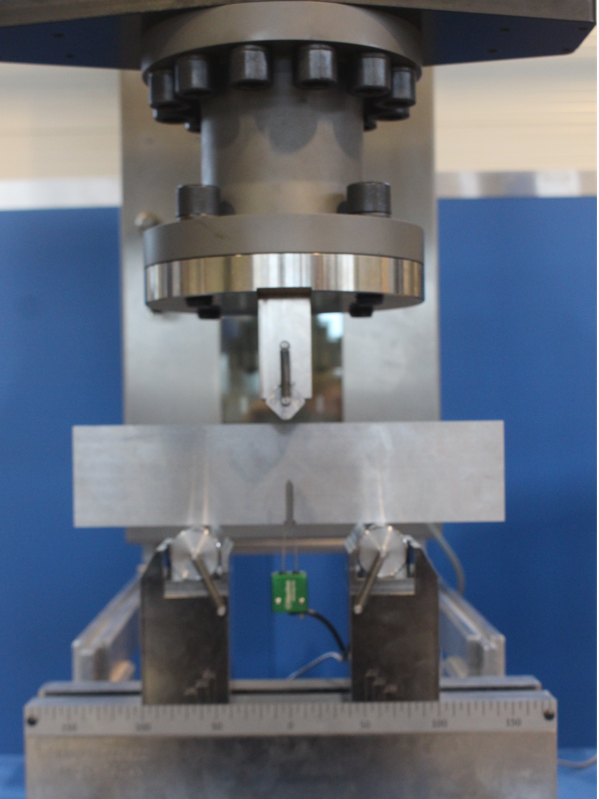

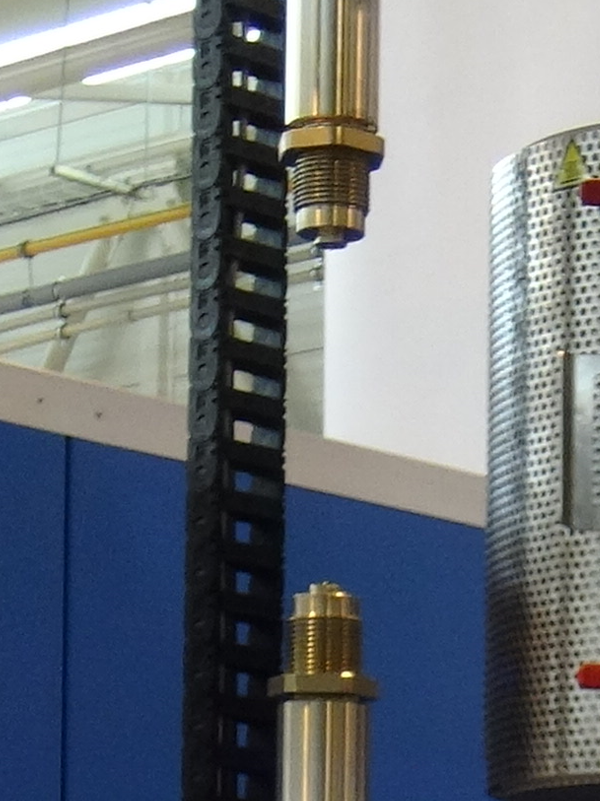

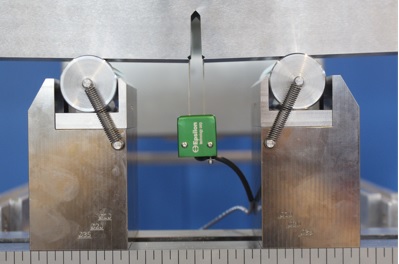

Tests with extensometers and measuring probes

Tensile test with extensometers in accordance with EN ISO 9513, EN 6892-1, ISO 12106, ASTM E606, DIN 50100, ASTM E399, ASTM E647, ASTM E466, etc.

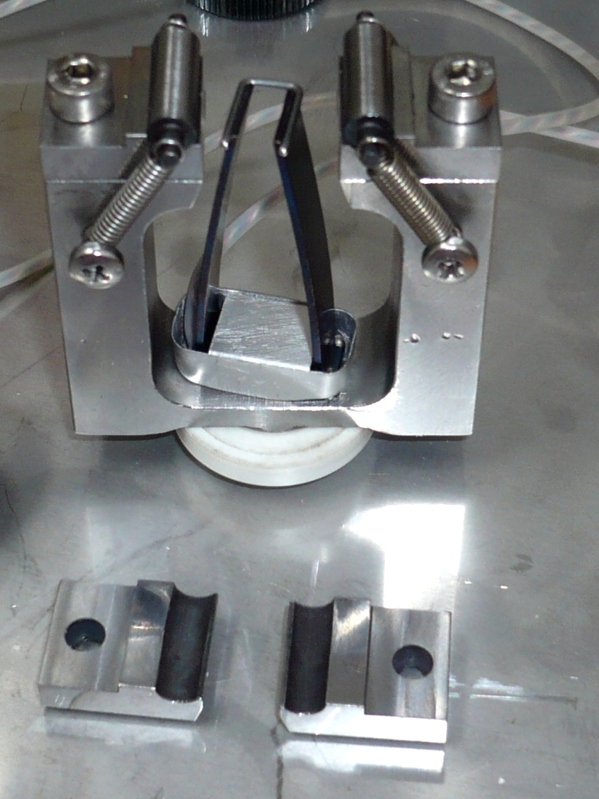

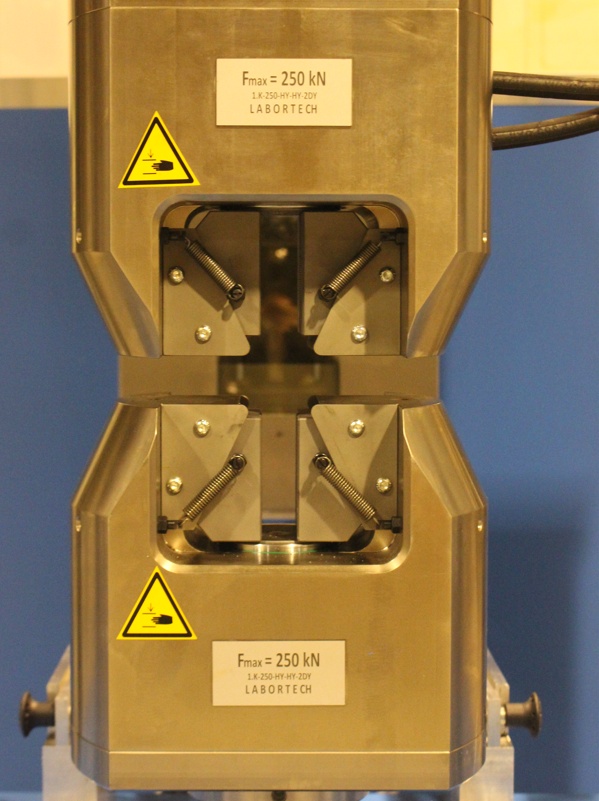

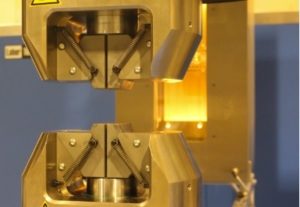

Test with various jigs and clamping grips

Various types of clamping grips and test fixtures for fastening and dynamic testing of metals, carbon, plastics, laminates, etc. for dynamic tensile, compressive and bending tests according to EN 6892-1, ISO 12106, ASTM E606, DIN 50100, ASTM E399, ASTM E647, ASTM E466 etc.

Test with high temperature furnace and temperature chamber

High temperature tensile and compressive dynamic tests according to ISO 6892-2 Method A1, EN 6892-1, ISO 12106, ASTM E606, DIN 50100, ASTM E399, ASTM E647, ASTM E466 etc.

MEZERA

Basic set of a dynamic testing machine

Focus on these 3 basic machine parts…

Machine frame – hydraulic servo cylinders – edge coaxiality corrections

Machine frame

First of all, consider what you want to try. Based on this consideration, select the machine frame – series 00 or series 01.

If you have a high frequency of adjustment of the working space, then complete the machine with an automatic electro-hydraulic transfer and clamping of the crossbar.

Hydraulic servo-cylinder

For the H.5 series 00, a maximum piston rod stroke height of 100 mm is recommended. It also depends on which HA you chose from the previous table and whether you use a classic dynamic sealing ring or a hydrostatic piston rod guide for higher lateral loads on the servo cylinder.

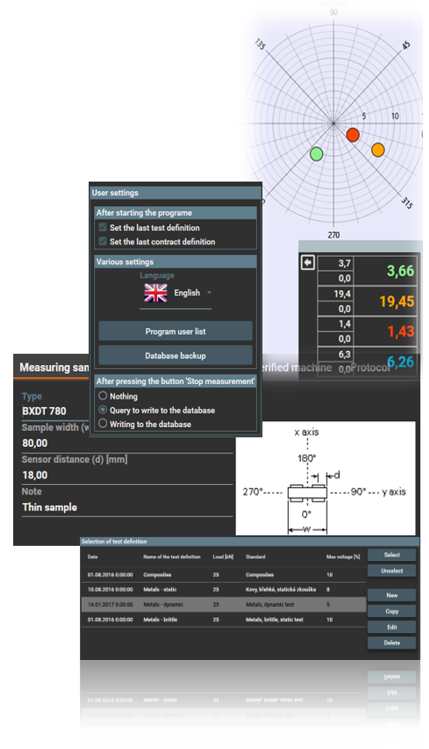

Coaxiality

Do you want to be sure? Use the BENTROD measuring and setting unit designed for evaluation and optimization of concetricity and edge coaxiality correction according to ASTM E1012, GES400 (NADCAP), GE450 and ISOTC 164SC5WG11

Selection of hydraulic unit including diagnostics

Hydraulic Unit (HA) selection

HA is designed as a compact hydraulic pressure unit designed for fatigue tests with water or air cooling.

HA equipped with HALT 18 – Diagnostic SIEMENS control system with system monitoring of conditions, pressures and service intervals via touch LCD.

Noise

The possibility of covering HA is made by a special anti-noise cover PAC <72 dB. Easy access from all sides using quick couplings allows easy handling around the HA (filter change, oil change, etc.). Thanks to the silent block suspension, the HA can be placed directly on the test room floor.

Hydraulic connection

The connection between the HAD hydraulic unit and the machine frame is made using the VOSSFORM system, including the pressure test. Oil stains and gutters have no chance.

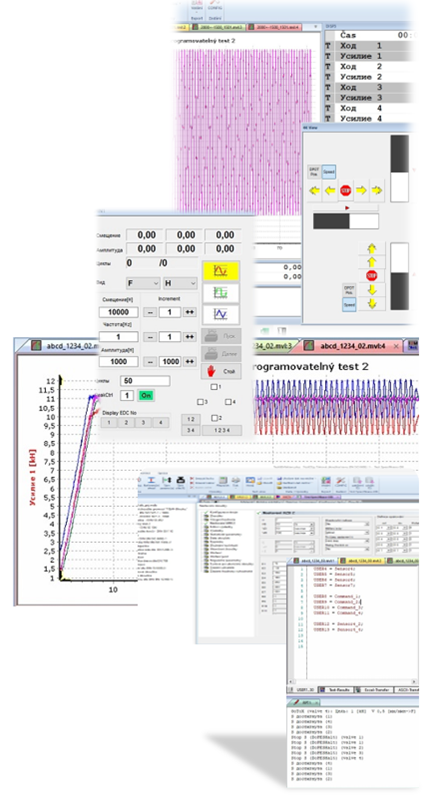

Appropriate selection of control unit and test software, including modules

Measuring and control electronics

EDCi Control electronics with synchronization of all measuring and control channels in real time with a sampling frequency of 10kHz.

Choose the RMCi7 or RMCi8 series remote control with OLED display integrated CENTRAL STOP.

Basic parameters of electronics

Analog signal resolution level ± 250,000 divisions (20 ms). Internal frequency 64 bit, data acquisition 32 bit, AD 24 bit, arithmetic, sampling frequency 10kHz. Integrated RS232 for VIDEO extensometers. PC connection – Ethernet 10/100 Mbit, USB 2.0.

Machine control and testing evaluation

Test & Motion + software – DYNPACK – intuitive software for long-term dynamic tests that you will fall in love with. All you have to do is choose the test modules according to the given test standards and you can test the samples.

MEZERA

Test&Motion+ – DYNPACK Software

Intuitive software for long-term dynamic tests…

Test & Motion + – DYNPACK – intelligent, intuitive and powerful software that will help you increase productivity and testing quality in your test rooms and testing laboratories. You can streamline, refine, and accelerate your testing and adapt your testing environment to make it easy for operators to measure the mechanical properties of materials in a dynamic single-axis or multi-axis test mode with support for EN, ISO, DIN, ASTM, and GOST standards.

BENTROD System

A solution that can precisely and easily set the coaxiality of a dynamic system

LABORTECH H.5 series test load frames exhibit excellent rigidity and coaxiality, which minimizes bending stress to increase test accuracy and reduce data scatter. Proper alignment prevents off-axis bending stress, which can degrade the sample (sampling and production is very expensive) or the resulting data will be skewed and therefore unusable. BENTROD measuring and setting unit designed for evaluation and optimization of concentric and edge correction of coaxiality (clamping) of clamping grips for static and dynamic testing machines according to ASTM E1012, GES400 (NADCAP), GE450 and ISOTC 164SC5WG11.