H.10 – DYNAMIC AND STATIC TEST BENCHES

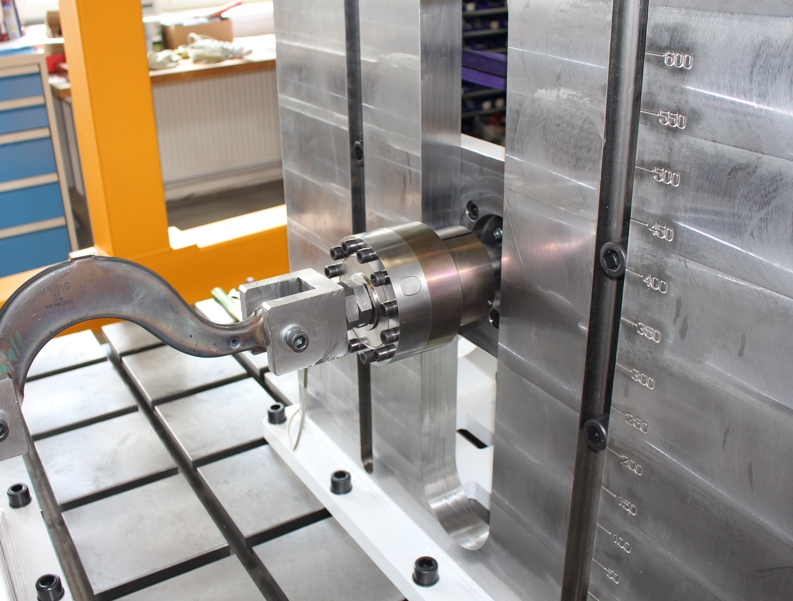

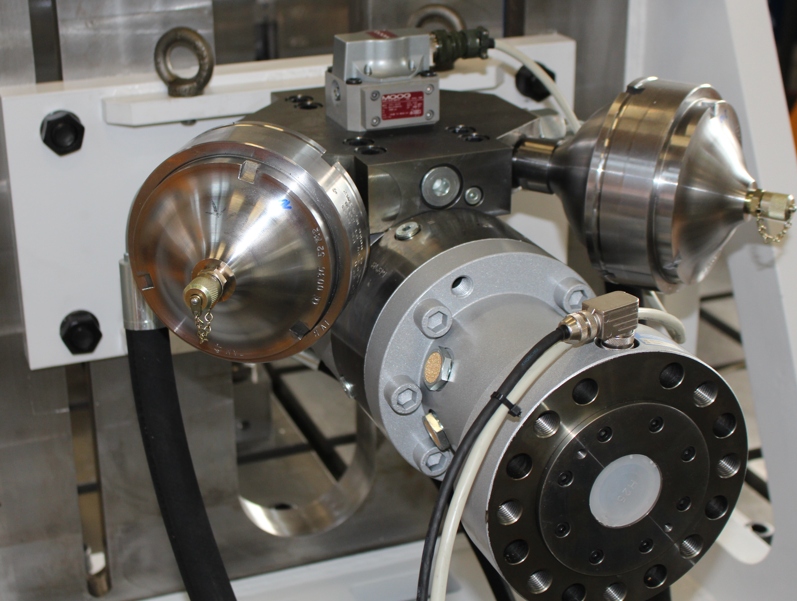

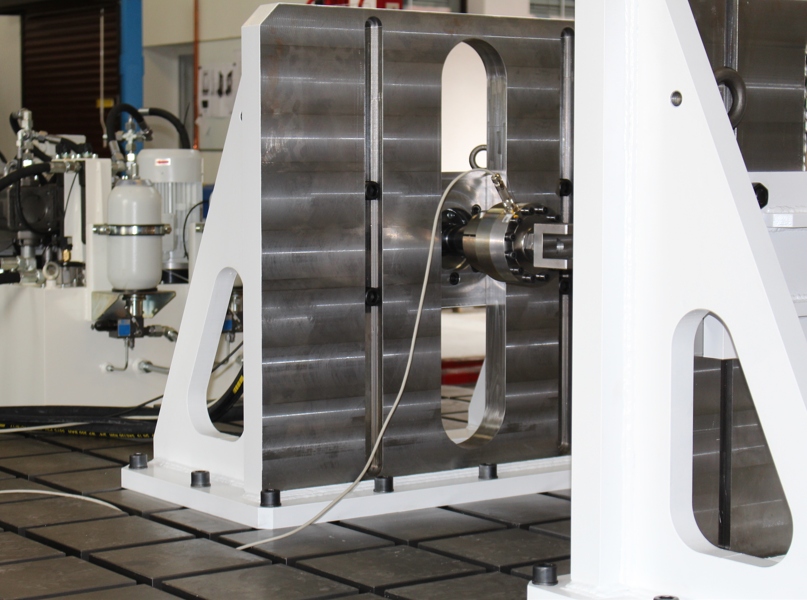

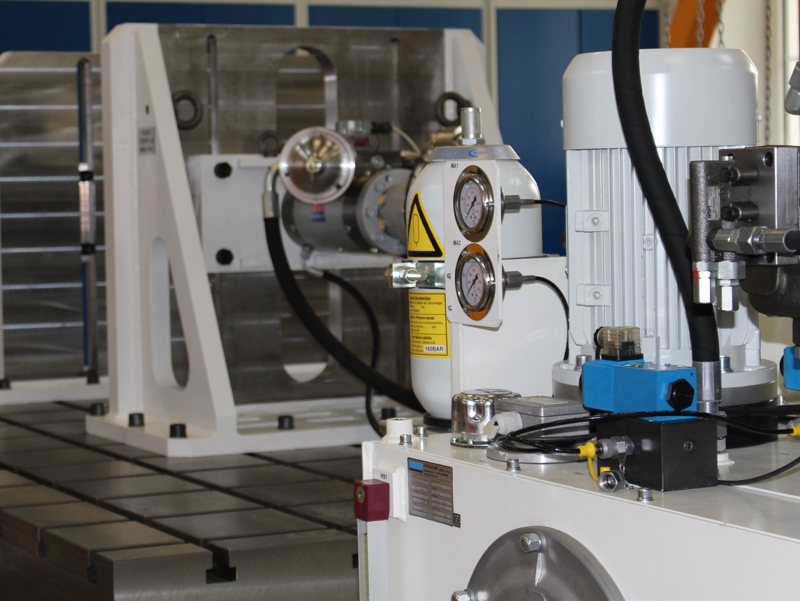

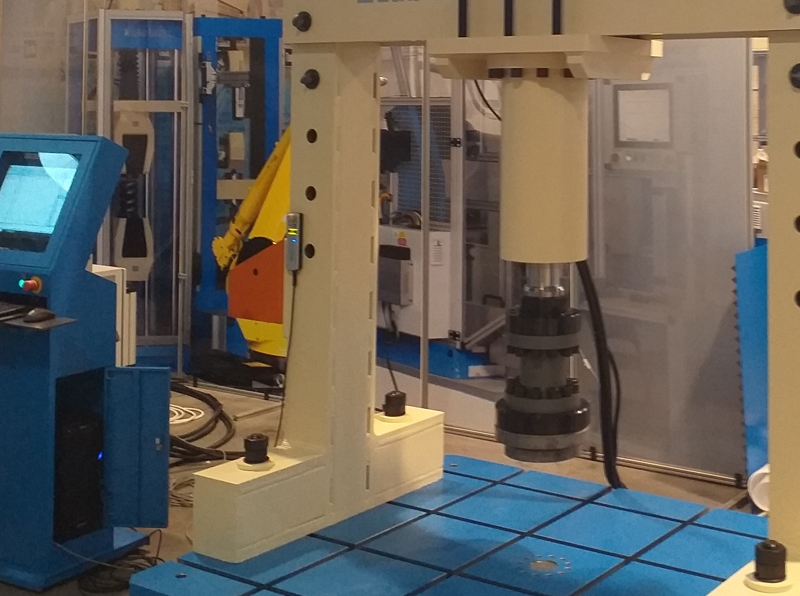

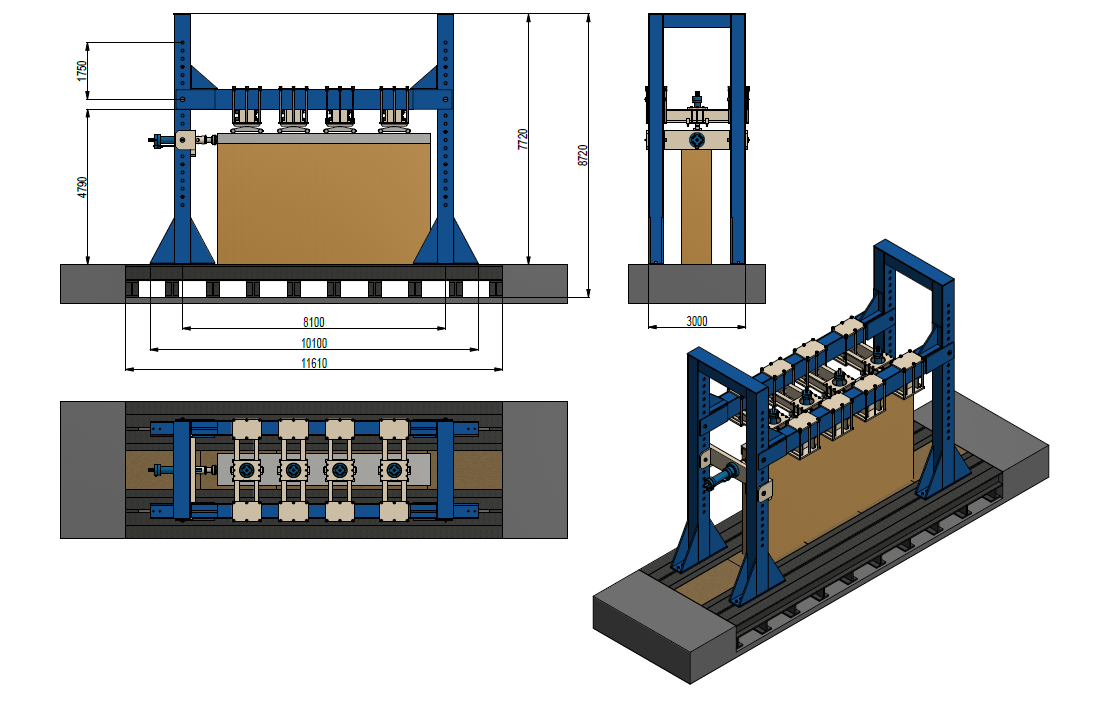

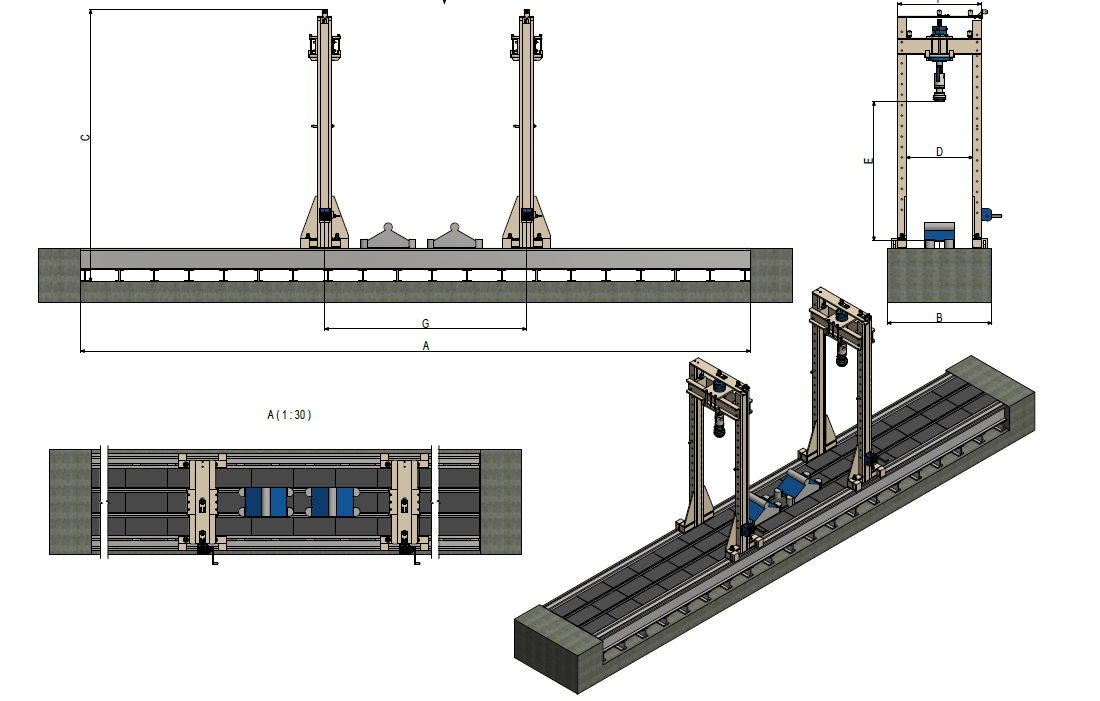

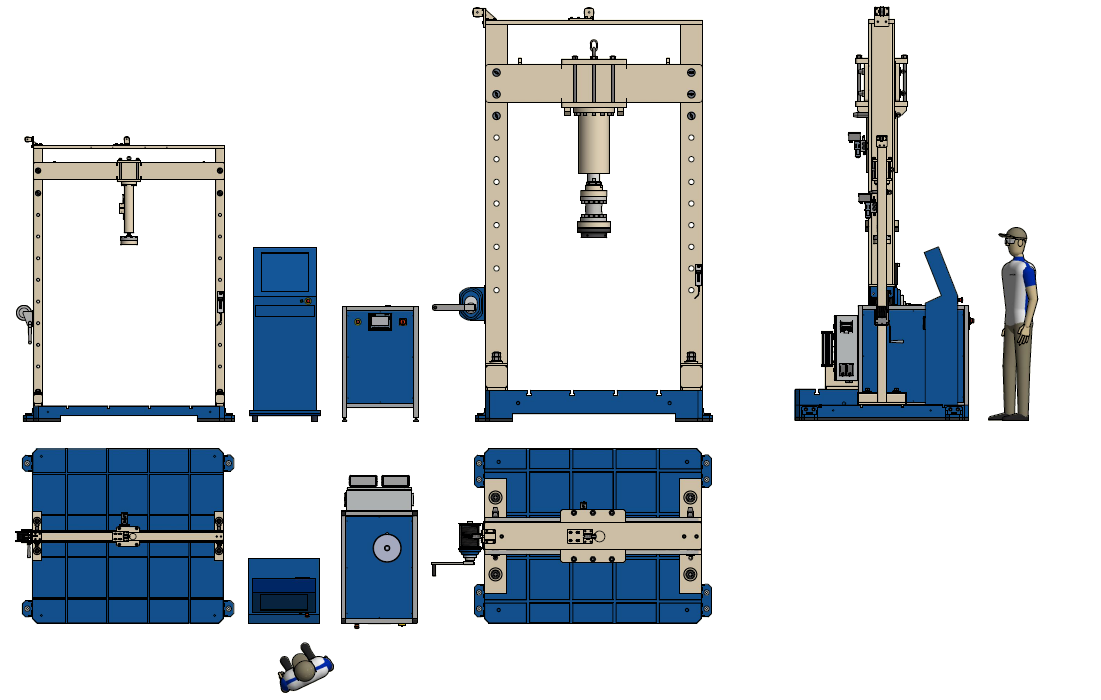

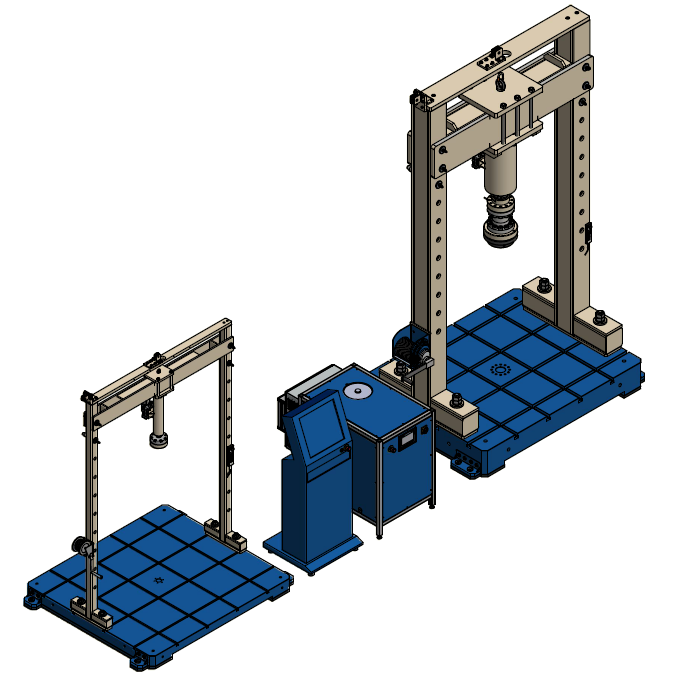

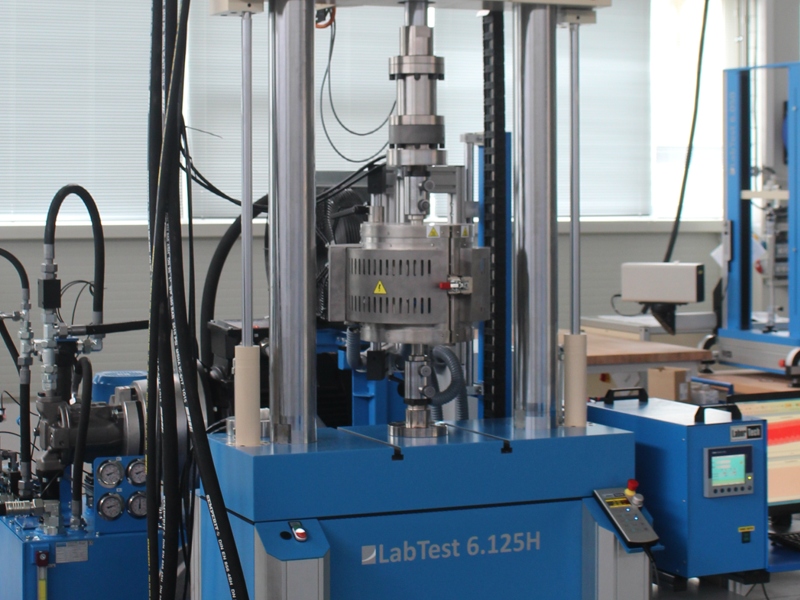

The dynamic hydraulic test benches of the H.10 series are designed for forces up to 10MN and use a platform of T-grooved plates or load-bearing structures. They are designed to perform low and high cycle fatigue tests of parts or entire products. This range of machines is characterized by high frame rigidity and mechanical resistance. The range of a given machine depends on the dynamic stroke, test force, frequency and sample size. A specific test set is derived from these parameters, which consists of a test frame – T-slot plate, a combined servo-hydraulic cylinder and a hydraulic unit.

Download:

MEZERA

General key features of the H.10 series

- Robust horizontal or vertical stand or table design with integrated hydraulic cylinders or electric actuators.

- The assemblies consist of T-slot plates of different dimensions and for different loads or directly T-slot profiles built into the concrete floors in the test halls.

- 3D simulation is a matter of course when developing these products.

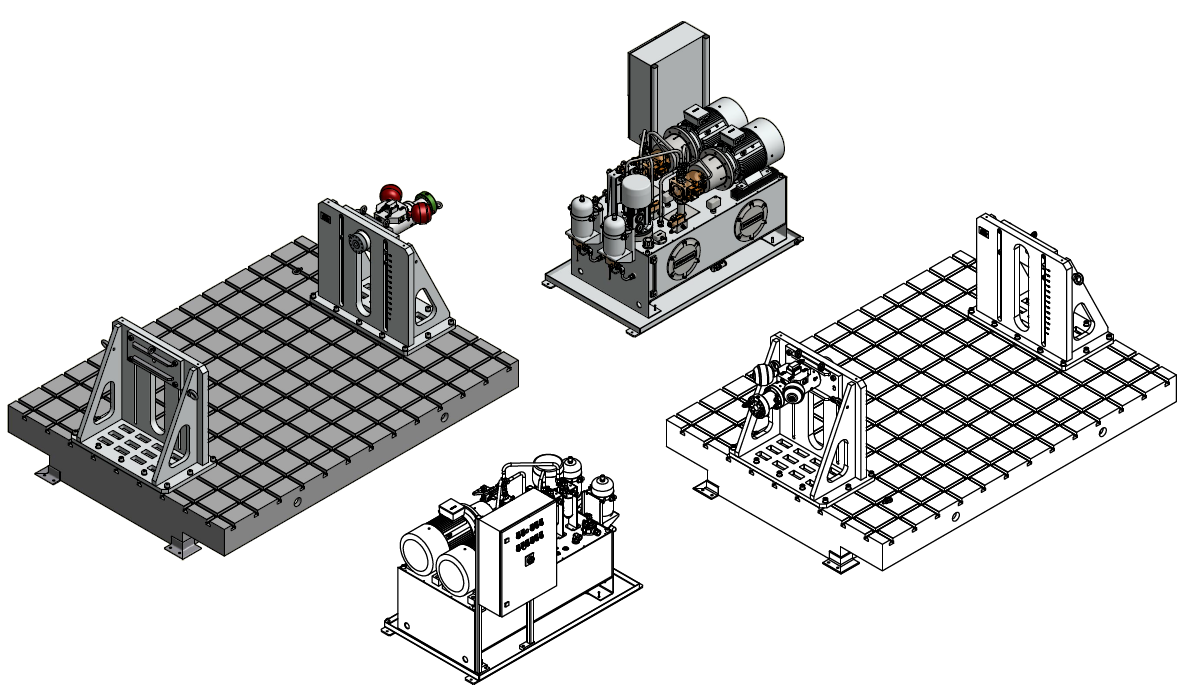

- Each servo-hydraulic test set of the H.10 series includes compact hydraulic units of the HAD or HAS series operating with a maximum constant pressure of 210, 280 or 350 bar.

- Monitoring of all Hydrauli units states is performed by the HALT 18 unit with PLC Simatic and LCD display.

- The Hyudraulic unit design is always carried out according to the customer’s requirements and depends on the F max and the number of test axes.

- The Load cells on each actuator operate in the accuracy class according to EN ISO 7500-1, ASTM E4.

- The machine is controlled by measuring and control electronics of the EDCi series with a sampling frequency of 2.5 or 10 kHz. Analog signal resolution level ± 250,000 divisions (20 ms).

- Possibility to control and set the machine using a touch LCD monitor and RMCi controller.

- Complete evaluation and control of the axial or combined torsion test is provided by the Test & Motion material testing software – Test&Motion – DYNPACK.

- Wide range of accessories – test pins, jigs, fixtures, etc.

MEZERA

VIDEOS on LabTest H.10 series testing machines

Hydraulic unit initialization including piston feed 1000kN

Initialization of the hydraulic unit HAD with HALT 18 diagnostics and setting of the piston rod with the RMCi 6 remote control

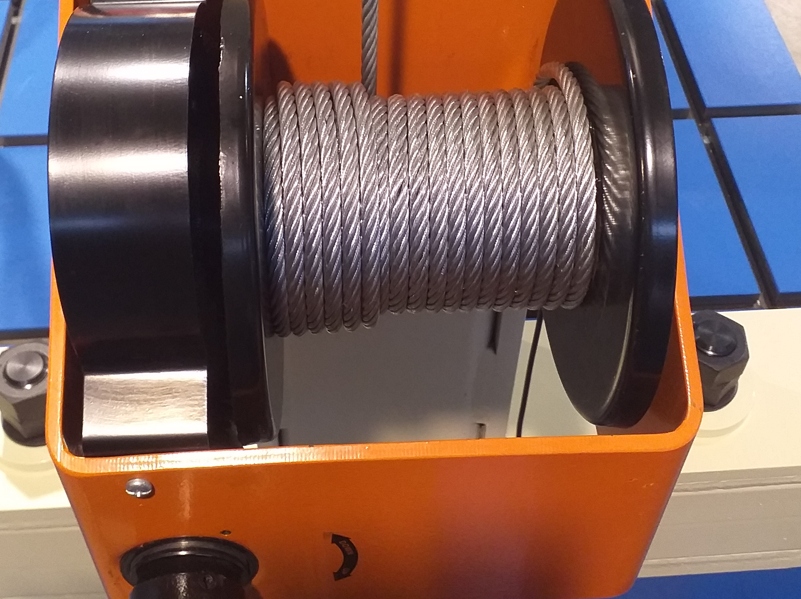

Mechanical movement of the crossbar at the 1000kN machine

Movement of the crossbar by a mechanical winder, including locking by means of pins for the H.10 – 1000 kN test series

Dynamic testing of car piston-hook

Fatigue test of the arm according to ČSN ISO 12106 – testing of uniaxially loaded test specimens by controlled deformation at constant amplitudes.

Horizontal adjustment of the crossbar on the machine

Horizontal movement of the crossbar by a mechanical winch, including locking by means of pins for the test series H.10 – 100kN

MEZERA

Do you have questions about our products?

Feel free to contact our product experts.

We look forward to your interest.

–

MEZERA

We offer technical solutions – WE ARE PROFESSIONALS

Individual approach to the design of fixtures and the machine itself …

MEZERA

Machine application

LabTest H.10 Series test systems provide a complete range of static and dynamic material stress testing, high cycle fatigue, material crack growth and environmental simulation on a variety of materials. These are mainly the aerospace, automotive, construction and railway industries.

- Construction industry – inspection of concrete and wooden parts and structural elements

- Automotive industry – multi-axis stress on bodies, elements, shock absorbers, etc. under extreme conditions

- Railway applications – railway superstructure – testing of mechanical properties and depreciation of tracks

- Aerospace industry – testing of wing parts, landing gear under extreme conditions, etc.

Tested parts

The dynamic and static hydraulic test benches of the H.10 series are ideal for testing the following parts:

- Testing of building elements according to standards: EN 124-1, EN 12390-3:2009, EN 12390-4:2001 atd.

- Testing of Automotive elements, samples and parts according to standards: ASTM E466, ASTM E399 ASTM E606, ASTM E647 ISO12106, DIN 50100 atd.

- Testing of building elements, samples and parts according to standards: EN 408, EN 26891, ASTM E466, ASTM E399 atd.

- Testing of building units according to standards: EN ISO 594, EN ISO 12512, EN ISO 21581, EN 26891, EN 408, ASTM E466, ASTM E399

Give us a drawing of the tested part and we will design everything for you.

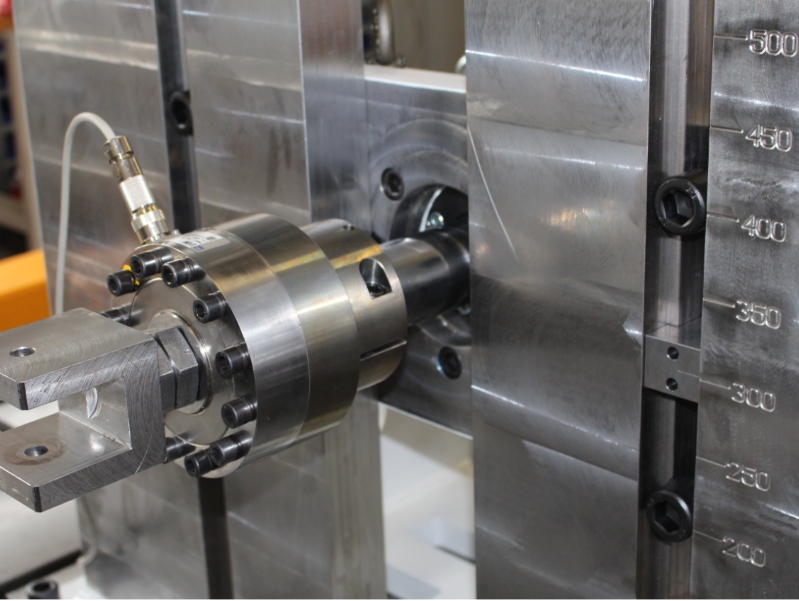

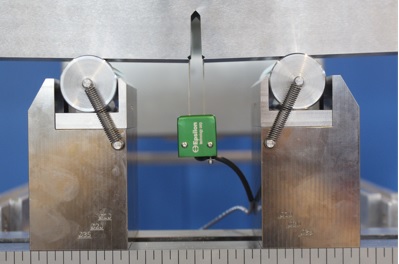

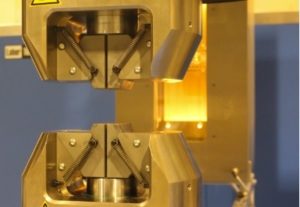

Fixtures design

Each component tested on the H.10 series dynamic and static hydraulic test benches shall have 100% test fixtures that have:

- Vysokou přesností

- Souosostí

- Tvrdostí

- Houževnatostí

- Mechanickou odolností

All fixtures are constructed in a 3D CAD INVERTOR with detailed diagnostics using the FEM method, manufactured and subsequently subjected to demanding testing in our testing laboratory. We guarantee the result, we are professionals.

Test evaluation

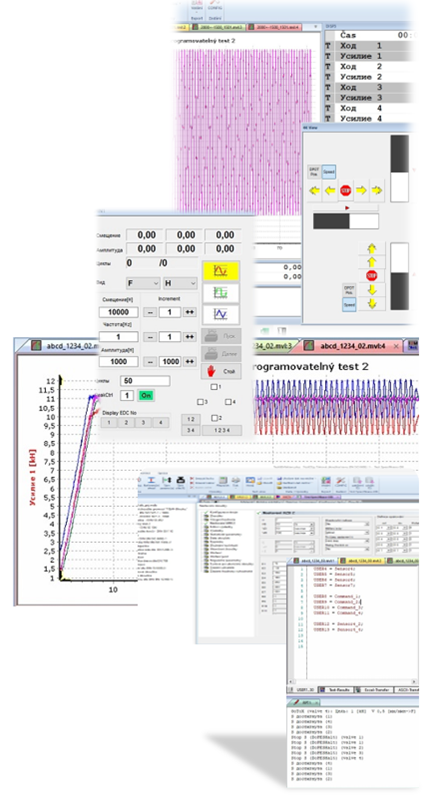

Test & Motion + – DYNPACK – intelligent, intuitive and powerful software that will help you increase productivity and testing quality in your test rooms and testing laboratories. You can streamline, refine, and accelerate your testing and adapt your testing environment to make it easy for operators to measure the mechanical properties of materials in a dynamic single-axis or multi-axis test mode with support for EN, ISO, DIN, ASTM, and GOST standards.

Say what you want and what you expect from the software and we will do it for you.

Our specialists are able to custom design and manufacture a machine or automated system with a high degree of quality and uniqueness. When designing fixtures, optimization often begins with details and in 3D STEP formats or DWF viewers. When developing LABORTECH products, we place great emphasis on the quality, design and affordability of our products. In the design of machines and systems, we pay attention to the minimum environmental impact and ECODESIGN in accordance with the standard ČSN EN ISO 14001: 2016. We verify the accuracy, reliability, durability and mechanical resistance of our machines in a test and calibration center.

MEZERA

MODULAR SOLUTION OF TEST BENCHES H.10

Customer solutions – uniqueness down to the last detail, because detail matters ..

MEZERA

Software Test&Motion+ – DYNPACK

Intuitive software for long-term dynamic tests

Test & Motion + – DYNPACK – intelligent, intuitive and powerful software that will help you increase productivity and testing quality in your test rooms and testing laboratories. You can streamline, refine, and accelerate your testing and adapt your testing environment to make it easy for operators to measure the mechanical properties of materials in a dynamic single-axis or multi-axis test mode with support for EN, ISO, DIN, ASTM, and GOST standards.