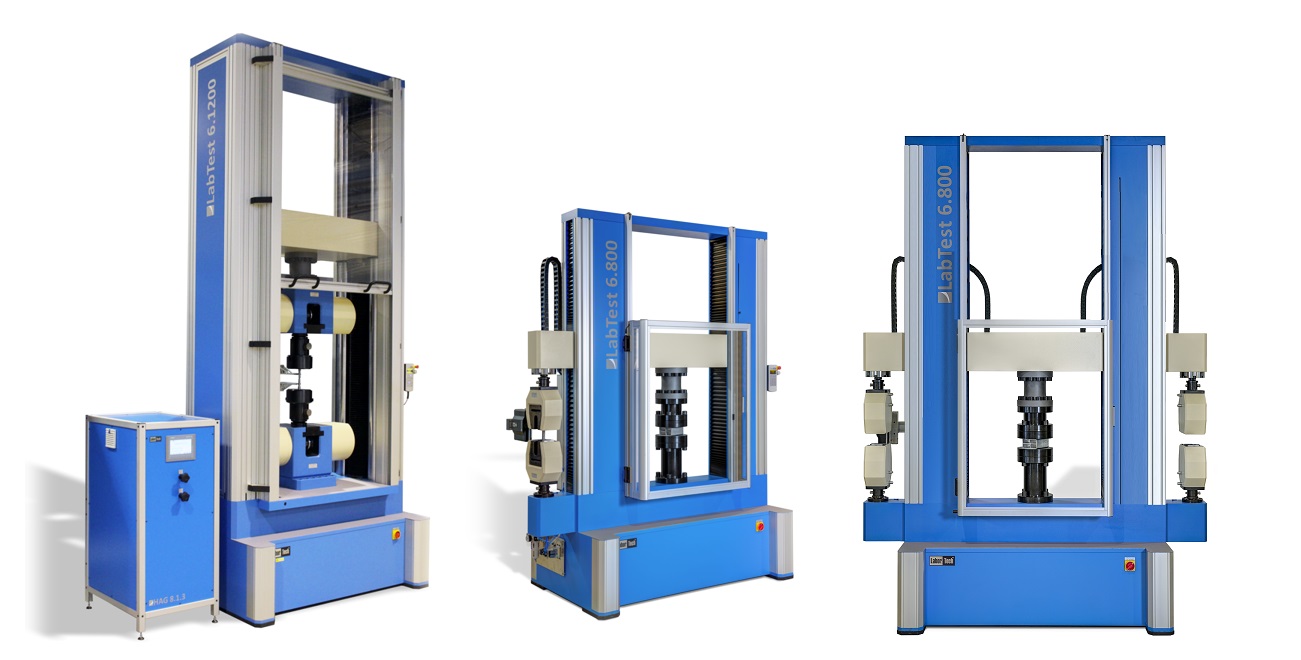

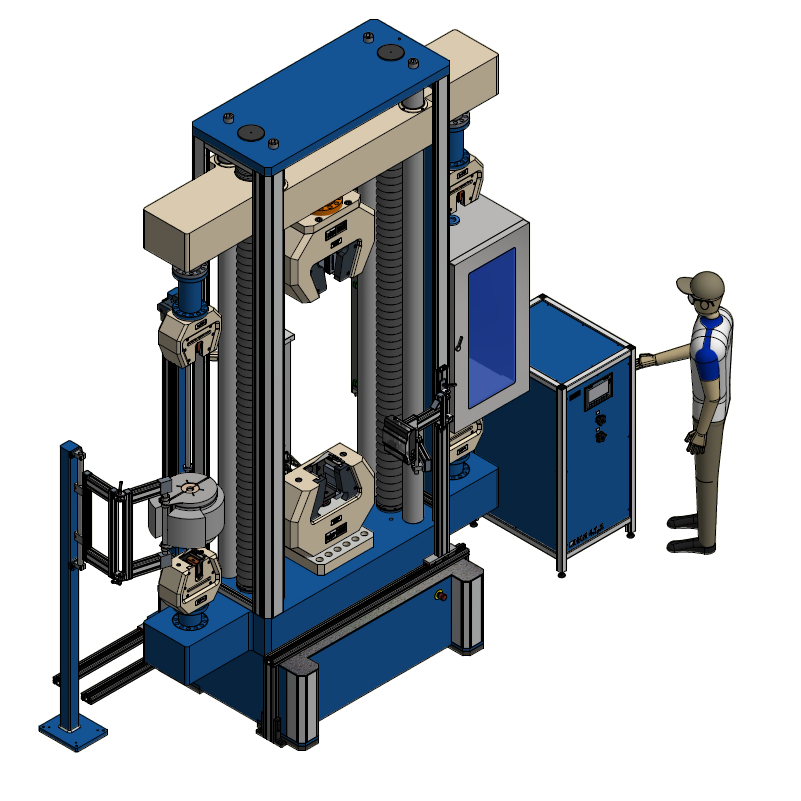

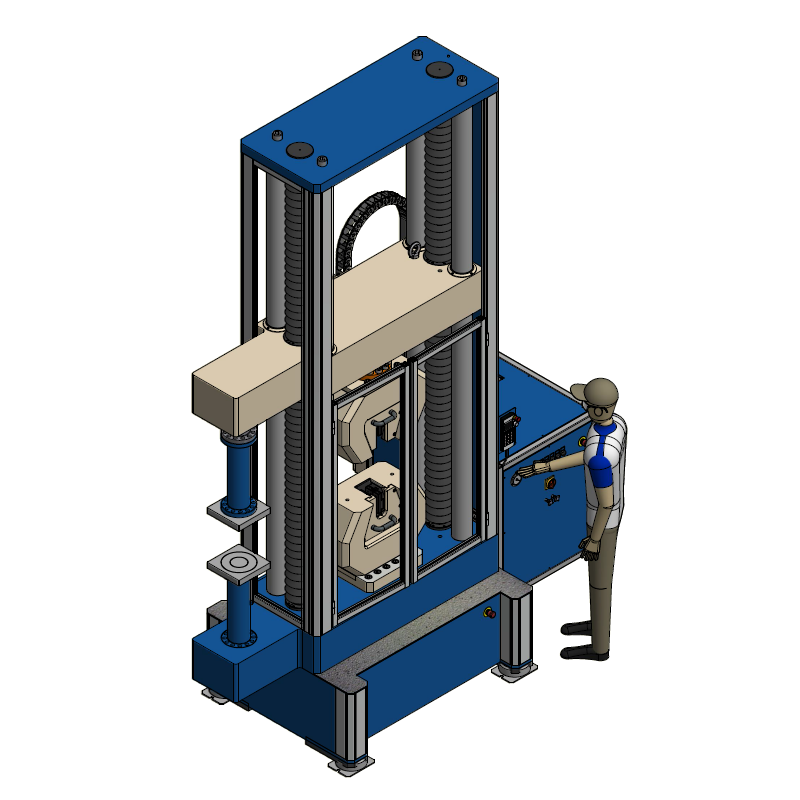

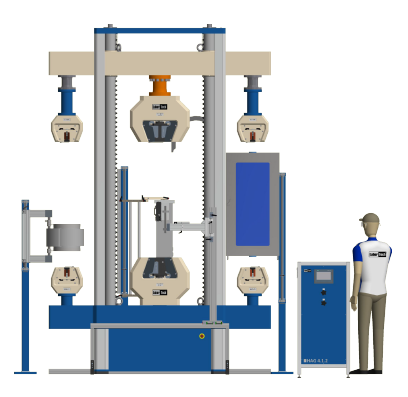

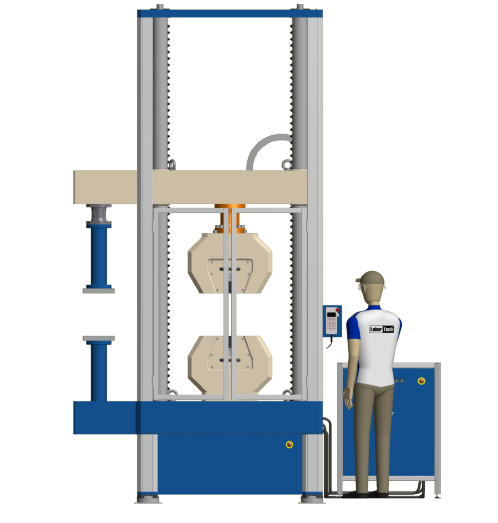

E.4 – HIGH-CAPACITY TESTING MACHINES UP TO 2000KN

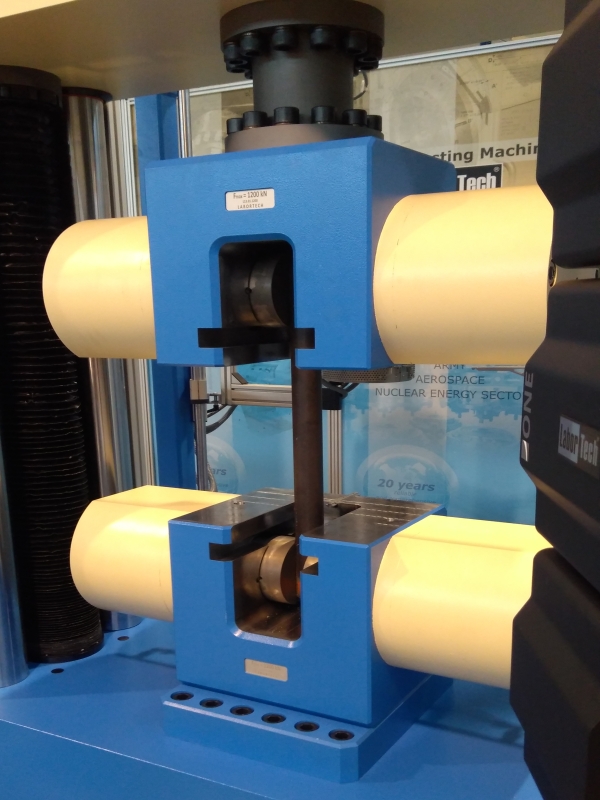

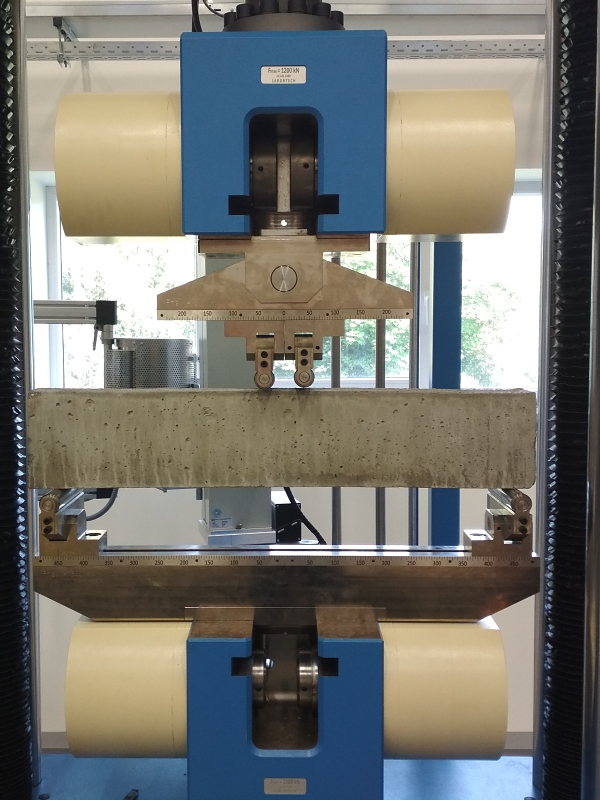

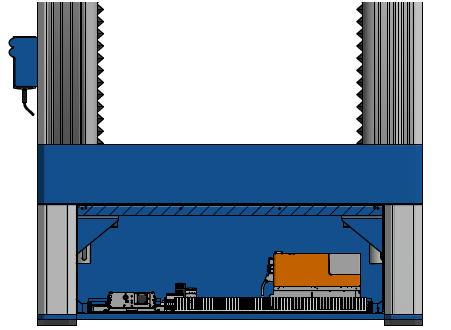

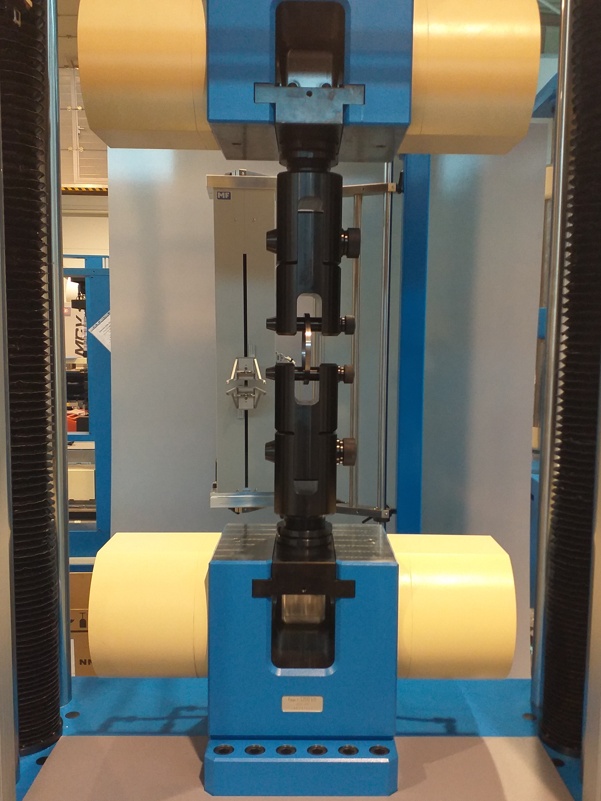

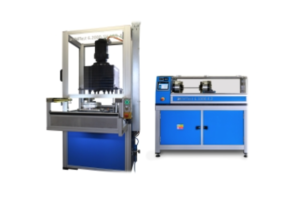

The high-capacity electromechanical testing machines of the E4 series in four-column floortop design up to 2000kN are suitable for both R & D and standard quality control in laboratories and operations. Combined with a wide range of accessories, the machine can be used safely and efficiently for testing of materials and products in tensile, compressive and bending conditions. These machines are primarily designed for testing metals and high strength materials. The models are available in the ranges of 1000kN, 1200kN, 1600kN and 2000kN.

Download:

MEZERA

Key features of E.4 series

- MEZERA

- MEZERA

-

- Robust vertical stand design with high rigidity, mechanical resistance and durability with integrated linear guide, ideal for off-axis loading.

- Abnormally high rigidity and mechanical resistance of the machine combined with ergonomics at a high level.

- Quiet and precise AC servo drive with low noise, high resolution with the possibility of control in the power and position loop.

- The E.4 series machines comply with all the above-mentioned EC directives on machinery and equipment and work in accordance with the new safety functions according to ISO 13850:2015.

- Automatic identification of sensors operating in the accuracy class according to EN ISO 7500-1, ASTM E4 with the possibility of linearization.

- The machine is controlled by measuring and control electronics of the EDCi series with a sampling frequency of 2.5 or 10 kHz. Analog signal resolution level ± 250,000 divisions.

- Complete test evaluation and management is provided by Test&Motion material testing software.

- Possibility to extend the frame by two or three test rooms.

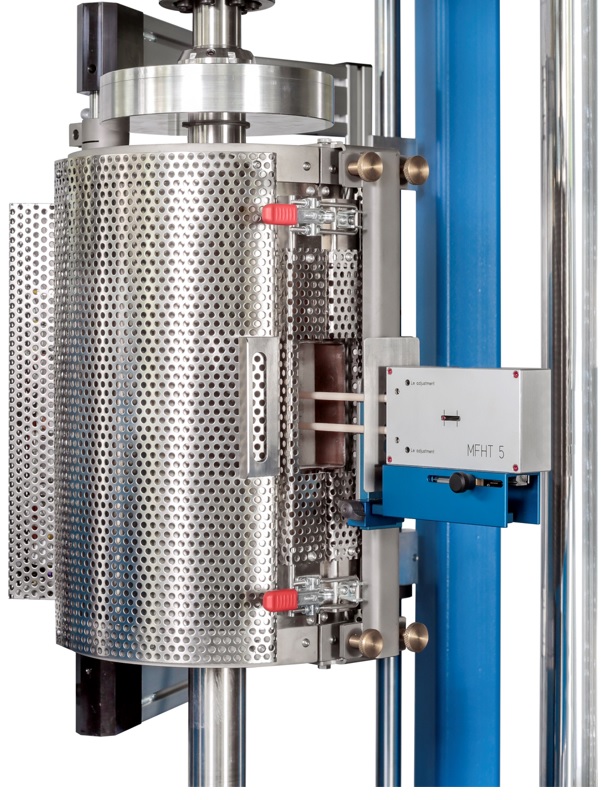

- High-precision tests with temperature chamber or high-temperature furnace.

MEZERA

Videos of LabTest testing machines E.4 series

Compression test on aluminum high-strength profile

High-strength compression test of profiled aluminum according to EN 586-2, EN 1301-2 and EN 603-2.

Tensile test with extensometer until full deformation

Tensile test on a standardized sample with extensometer until full tear (EN ISO 9513) according to EN ISO 6892-1.

Tensile test in Chuck grips with normalized sample

High-strength tensile tests controlled according to ISO 6892-1 in Chuck grips with standardized sample and extensometer until until full ripped of the sample.

MEZERA

Do you have questions about our products?

Feel free to contact our product experts.

We look forward to your interest.

–

MEZERA

TESTING ON LABTEST MACHINES WITH VARIOUS ACCESSORIES

You can test anything with our wide range of accessories…

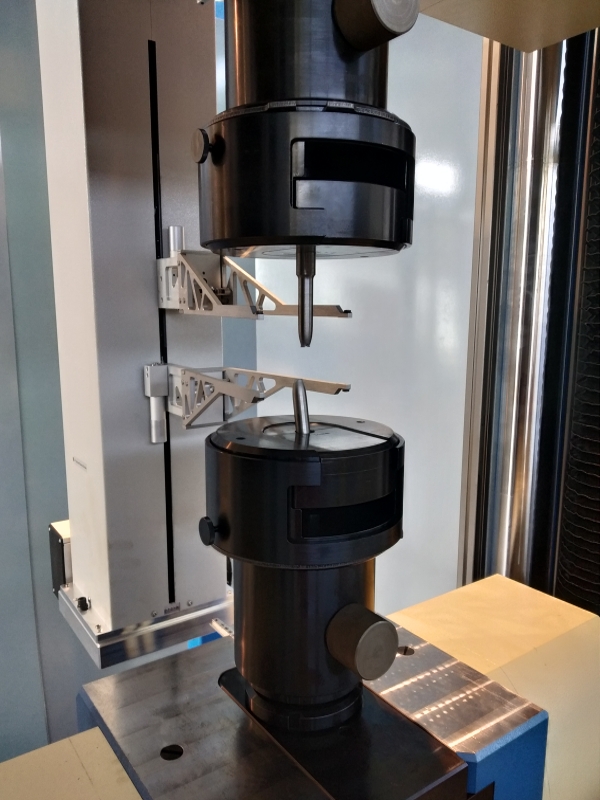

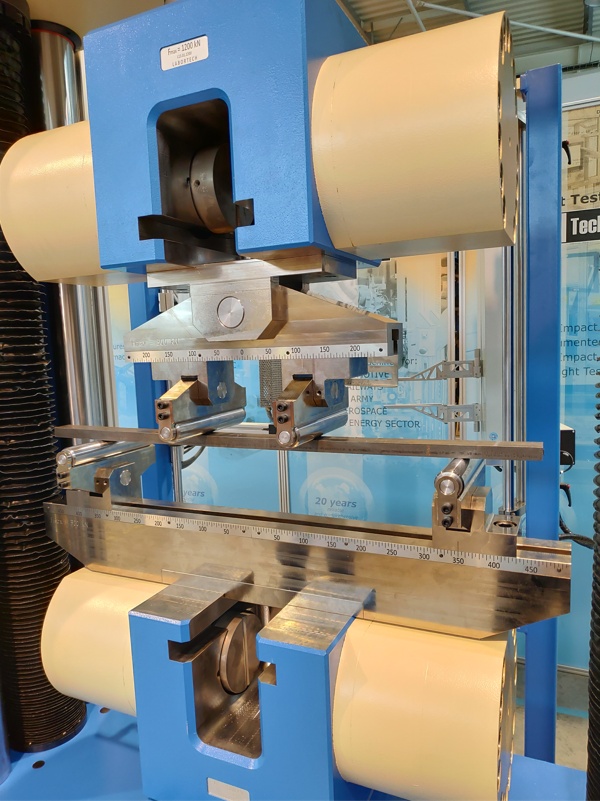

Tests with extensometers and measuring probes

Tensile test with extensometers in accordance with EN ISO 9513 and EN ISO 6892-1.

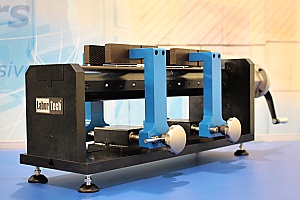

Test with various test fixtures and grips

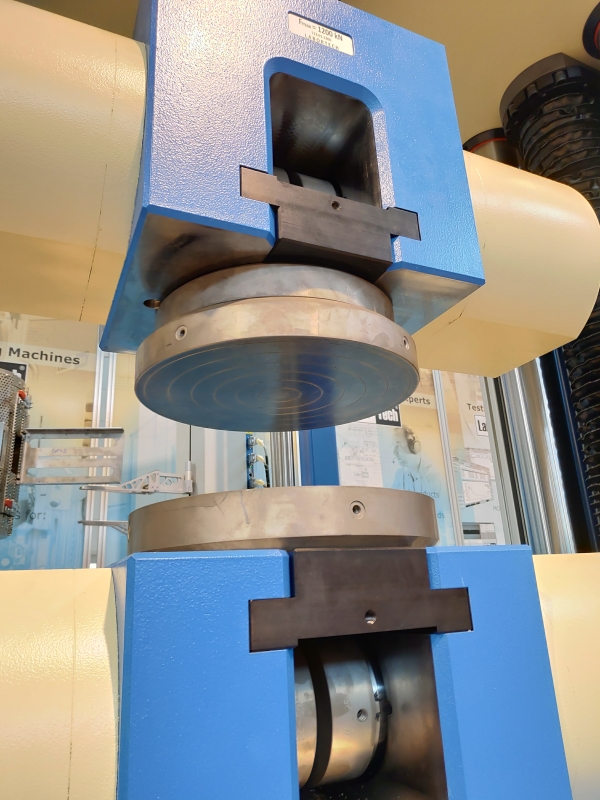

Various types of clamping grips and test fixtures for fixing metals, carbon, plastics, laminates, etc. for tensile, compressive, bending and torsion tests according to EN 6892-1, EN6892-2, EN 527-1, etc.

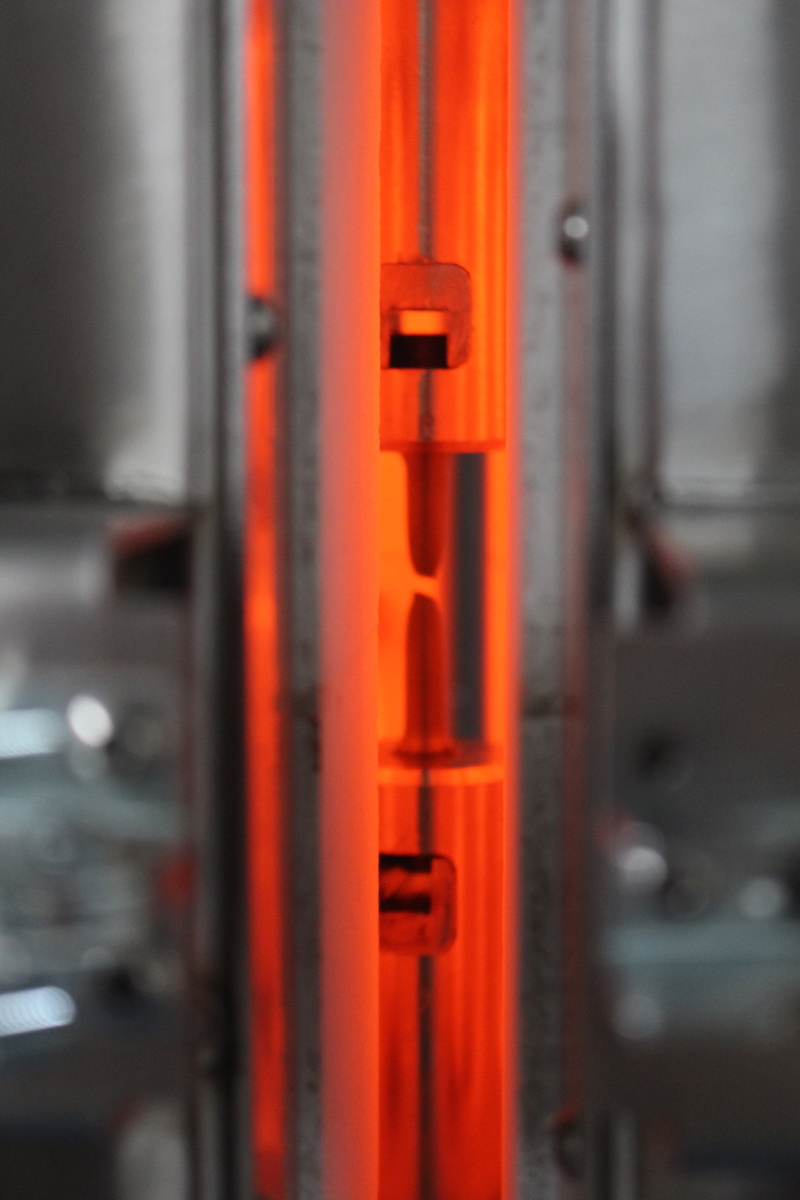

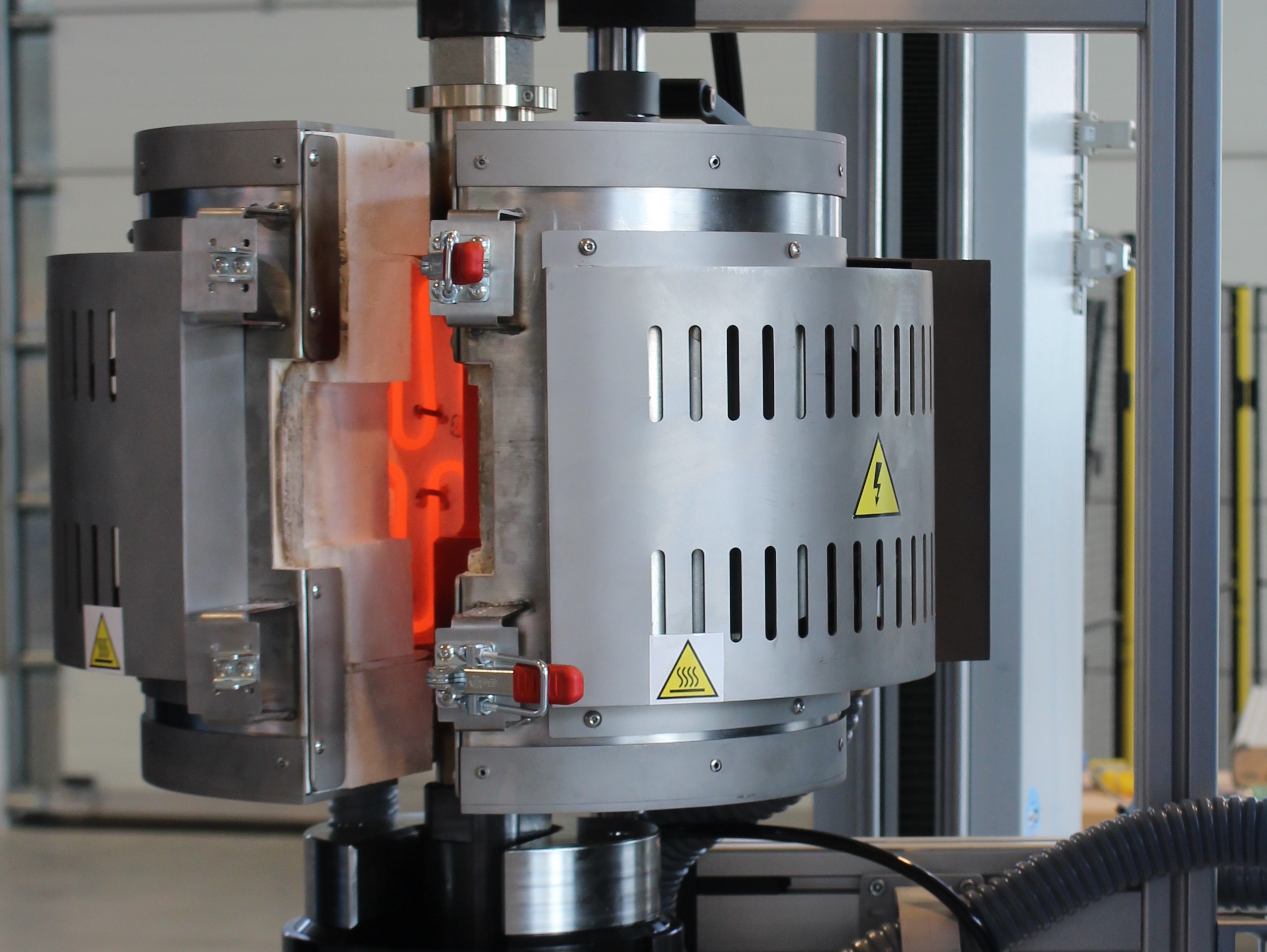

Test with high temperature furnace and temperature chamber

Tensile tests with high temperature furnace up to 1600 °C according to ISO 6892-2, temperature chamber with temperature ranges from -196 ° C to 450 °C.

MEZERA

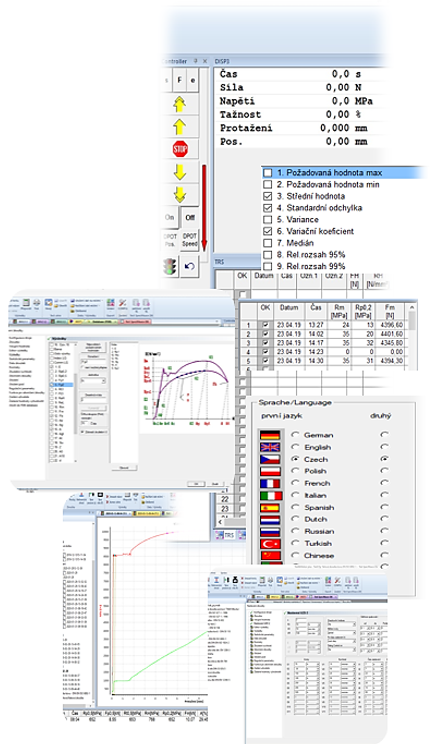

Test&Motion+ software

Intuitive software for tensile, compressive and bending tests…

Test & Motion + – BASIC – intelligent, intuitive and powerful software that will help you increase productivity and testing quality in your test rooms and testing laboratories. You can streamline, refine, and accelerate your testing and adapt your testing environment to make it easy for operators to measure the mechanical properties of tensile, flexural, and torsional materials with EN, ISO, DIN, ASTM, and GOST standards.

MACHINES E.4 BUILT FOR PERFORMANCE, RELIABILITY, ACCURACY AND SAFETY

A first-class product with high utility value and durability

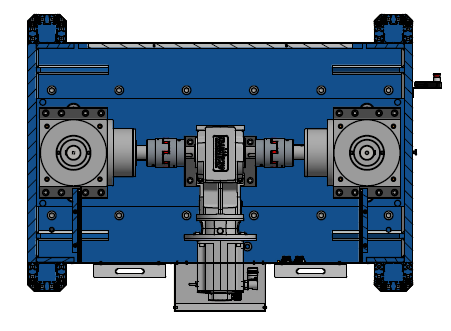

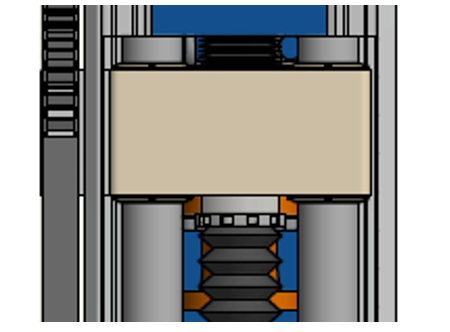

High precision gear, drive and motor unit

Powerful motors with spare capacity and greater dynamics.

Maintenance-free non-commutator AC servomotors designed for long-term testing.

Backlash-free precision gearboxes for high accuracy, rigidity and low maintenance.

By a suitable composition of the transmission system, we have reduced the penetration of dirt into the machine.

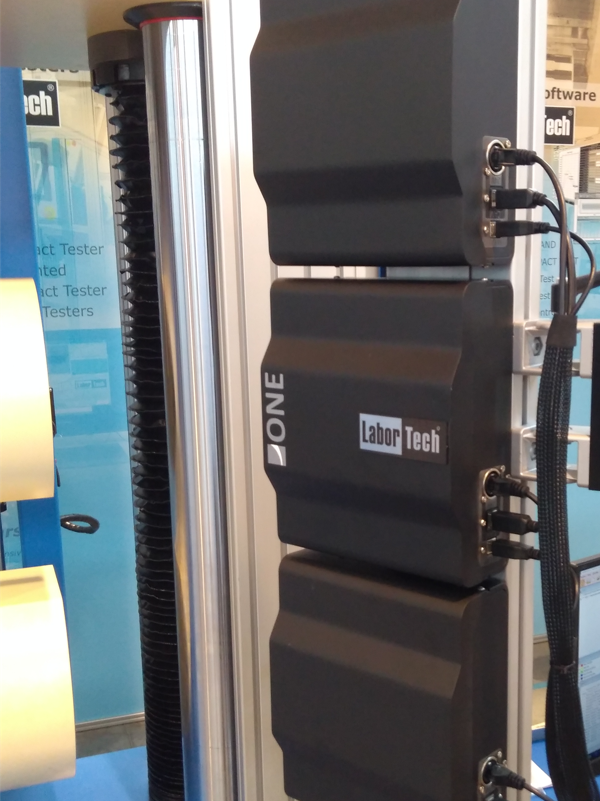

Measuring and control electronics of the entire testing machine

The measuring and control electronics are located at a safe distance directly below the test area.

The pull-out panel with electronics allows easy service access and, when inserted into the machine, eliminates the penetration of dirt into the interior of the machine.

The electronic system is designed so that peripherals such as a hydraulic power unit, robot, extensometer, etc. can only be connected using a connector.

Precise crossbar guidance ensures flatness and alignment

Precise crossbar guidance with standard bushings.

High rigidity for off-axis loading thanks to precise guide rods.

Ball screws manufactured in accordance with ISO 3408 and accuracy class P1 with preloaded bearings guarantee high accuracy.

Crossbar rigidity guaranteed by FEM plate with practical crossbar deflection less than 3.15×10-4 mm / N.

MEZERA

WE OFFER INNOVATION AND TECHNICAL SOLUTIONS

Customer solutions – uniqueness until to the last detail

MEZERA

- Our specialists are able to custom design and manufacture a testing machine or automated system with a high degree of quality and uniqueness

- In the case of technically advanced products, optimization often begins with details and in 3D STEP formats or DWF viewers.

- When developing LABORTECH products, we place great emphasis on the quality, design and affordability of our products.

- In the design of machines and systems, we pay attention to the minimum environmental impact and ECODESIGN in accordance with the standard EN ISO 14001: 2016.

- We verify the accuracy, reliability, durability and mechanical resistance of our machines in a test and calibration center.

MEZERA

Interesting customer applications

MEZERA

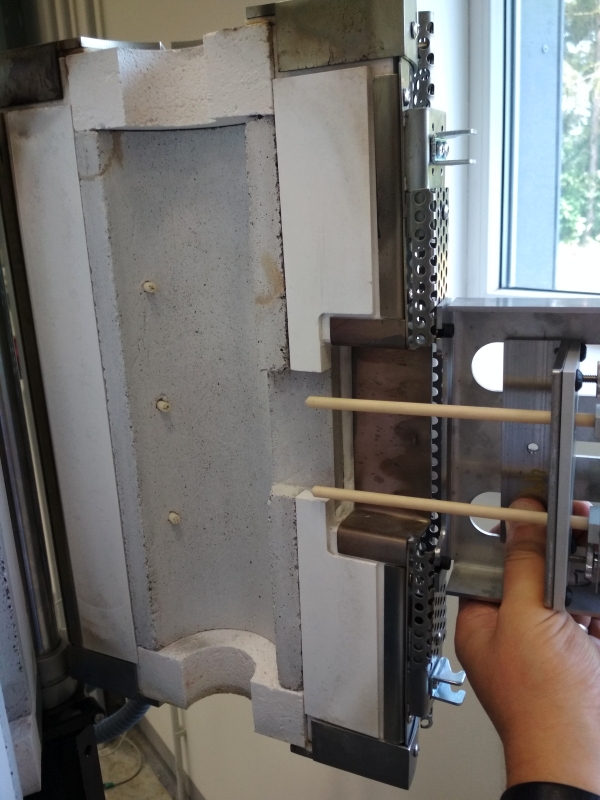

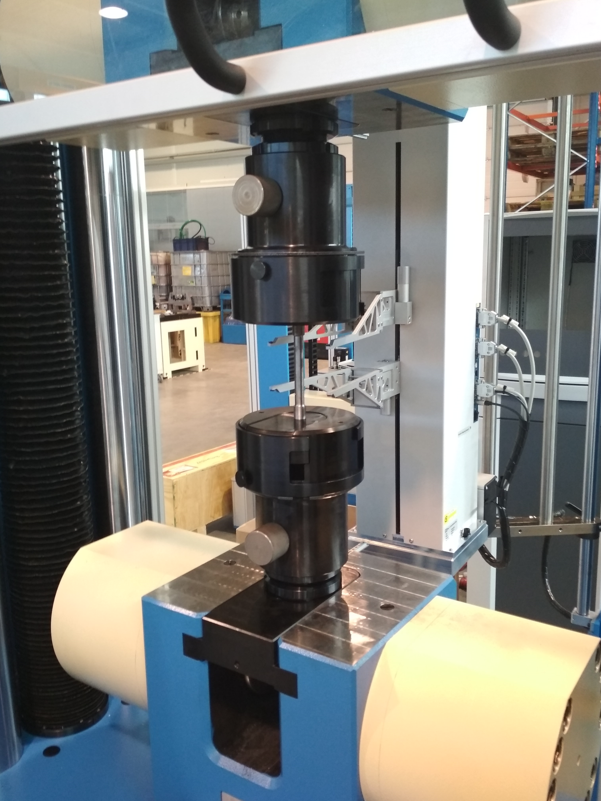

ENGINEERING testing of steel pipes

Tensile testing according to EN ISO 8496 metallic materials – Pipes – Ring tensile test The standard specifies a method of testing pipes by pulling a ring to detect surface and internal defects by deforming the test specimen until fracture occurs. This test can also be used to evaluate the plasticity of pipes. The ring tensile test is suitable for pipes with an outer diameter exceeding 150 mm and a maximum wall thickness of up to 40 mm. The inside diameter must exceed 100 mm.

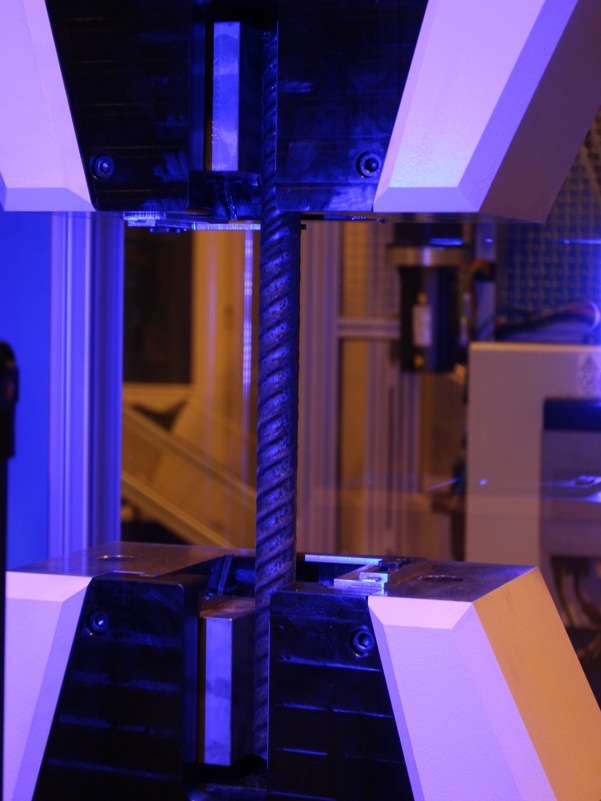

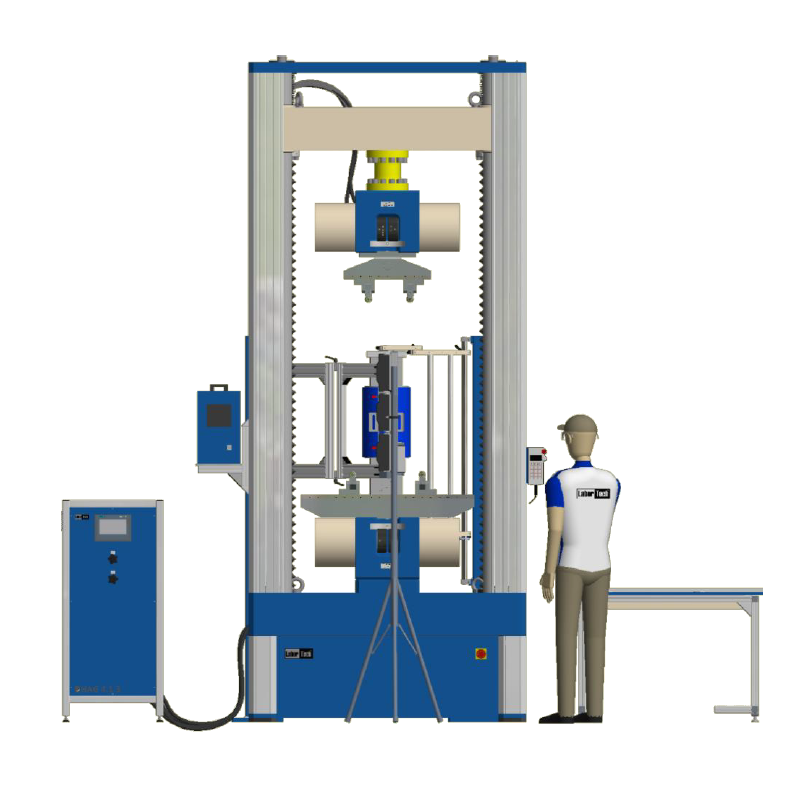

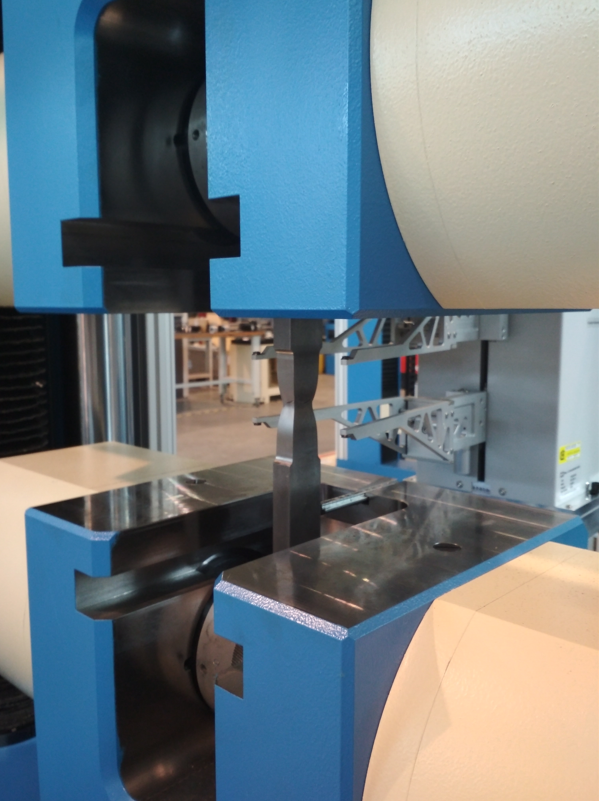

STEEL industry – creation of a NEW tensile-impact standard…

Research project focused on the creation of a new standard combining the basic tensile test at room temperature according to EN ISO 6892-1 and the impact test according to EN ISO 148-1 – Charpy impact test for the steel industry – production of pipes. practical measurement consists in 2D optical evaluation of the sample using 2 cameras that capture the structure of the sample and enter the measured values into the Test & Motion software.

t