HIGH-ENERGY DROP WEIGHT TESTERS TO 200 000J

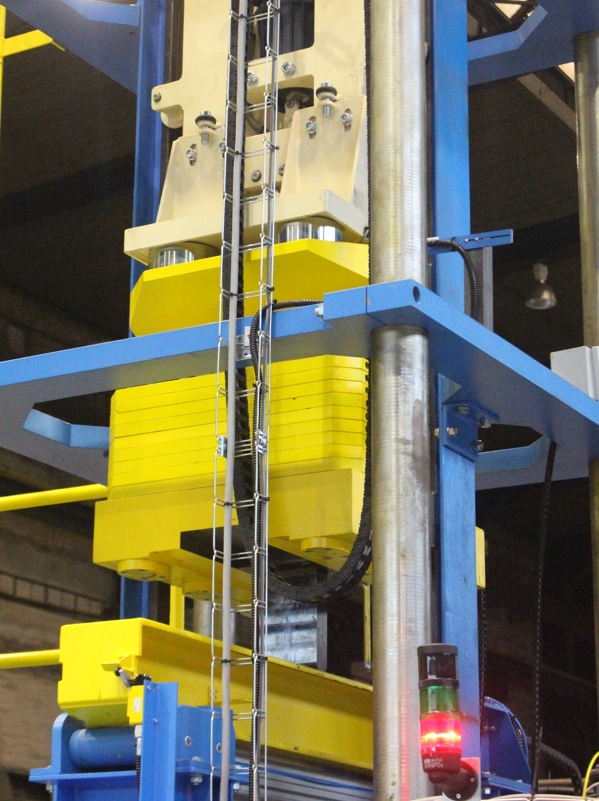

High-Energy parachutes of the DP series. 3 with a nominal energy of up to 200,000J are intended for conducting tests of materials, samples in the area of high energies. Our equipment is used to test and simulate the behavior of materials and components at different speeds, energies, impact heights, collisions, accidental drops and repeated impacts. Parachutes are produced in several modifications and are designed in such a way that, in conjunction with an integrated touch LCD monitor with DROPTest-S software or a full-fledged PC with DROPTest – BASIC software, they fully meet customer requirements and test standards according to EN, ISO, ASTM, GOST, BS or NF.

Download:

MEZERA

KEY FEATURES OF THE DP.3 SERIES

MEZERA

pokud

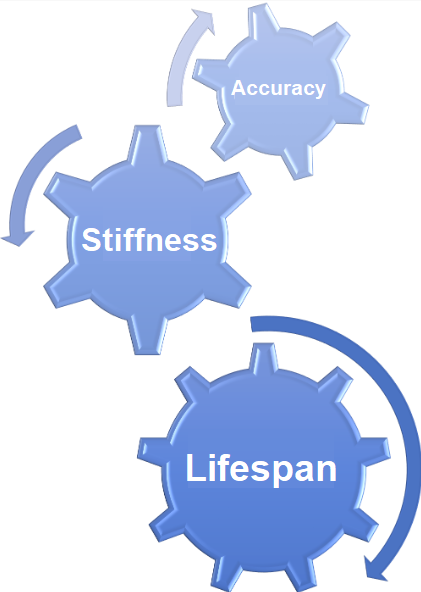

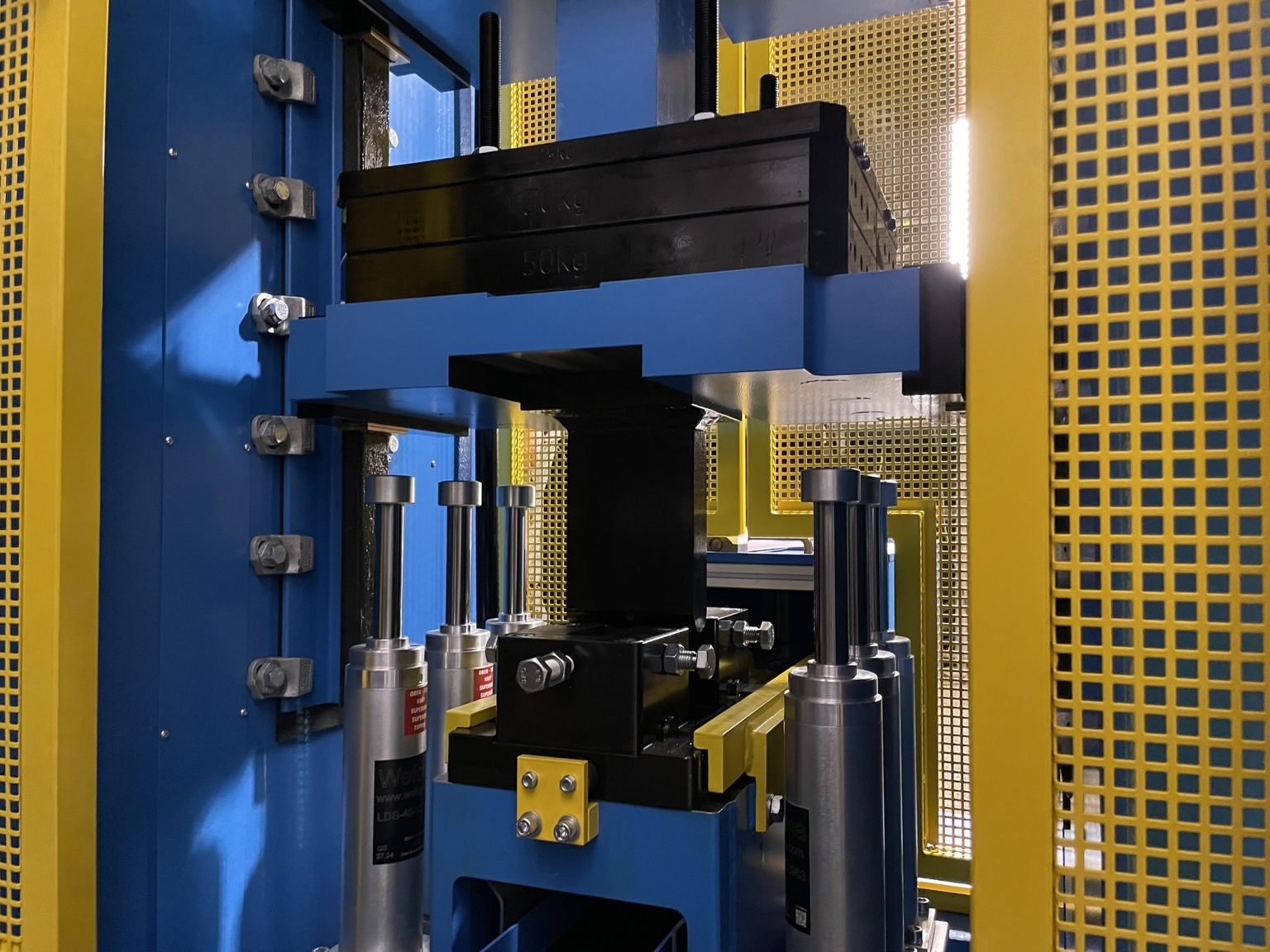

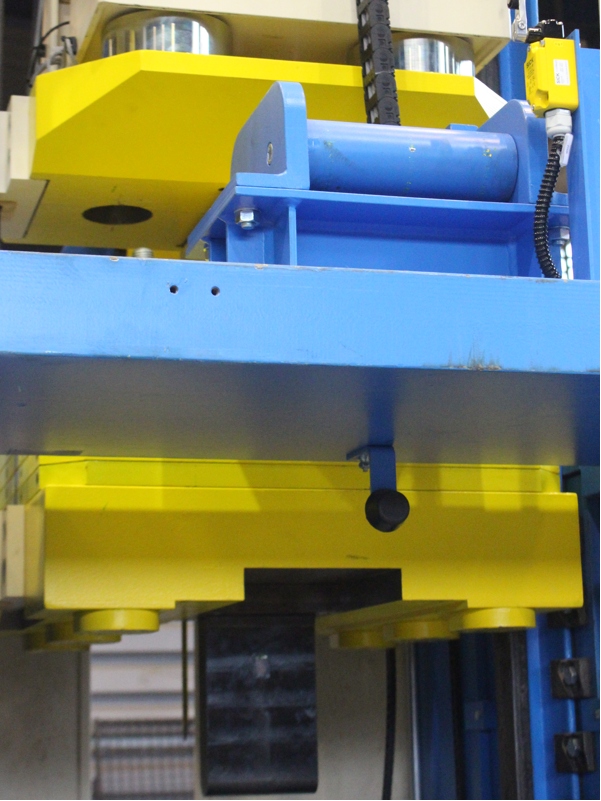

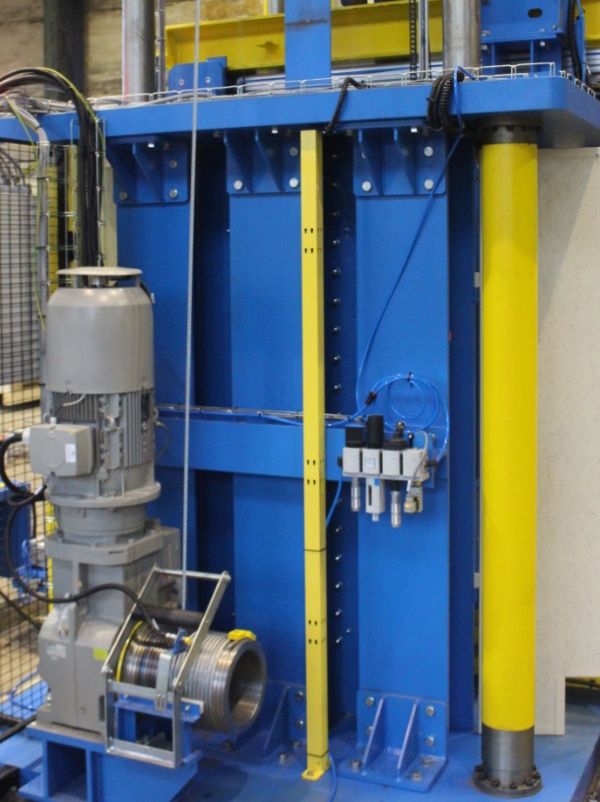

- Robust vertical frame with high rigidity and resistance to dynamic interference, durability, convenient ergonomic layout and maintenance-free operation.

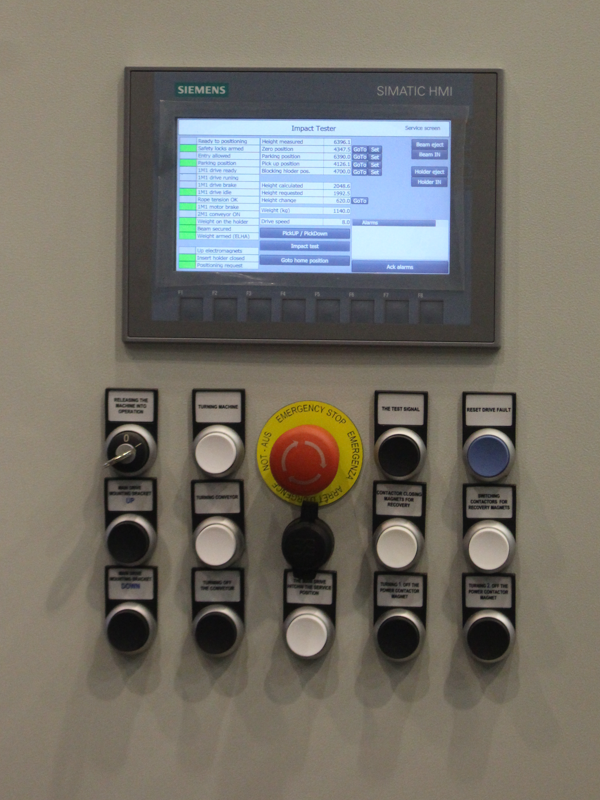

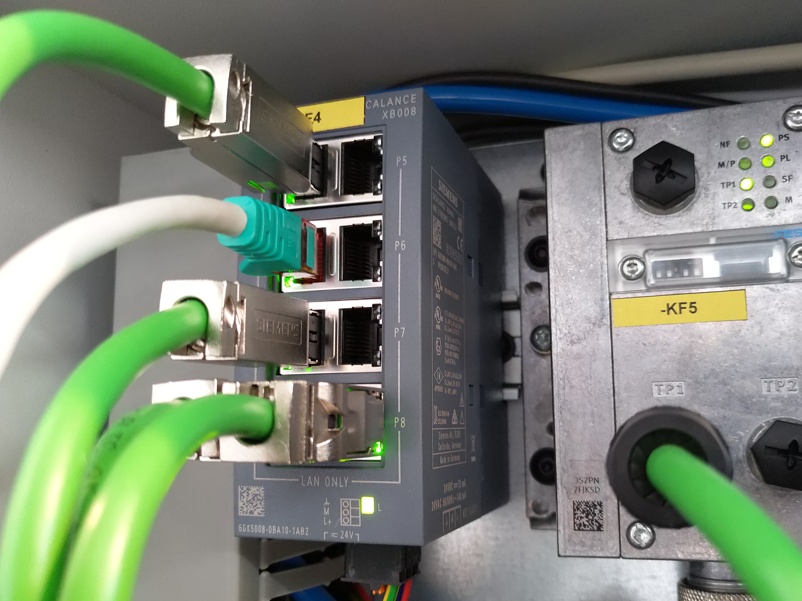

- The machine is controlled by a SIEMENS PLC with integrated touch LCD display with DROPTest-S software in the base of the machine.

- Complete evaluation and management of the test is ensured by the software for impact testing of materials DROPTest – BASIC

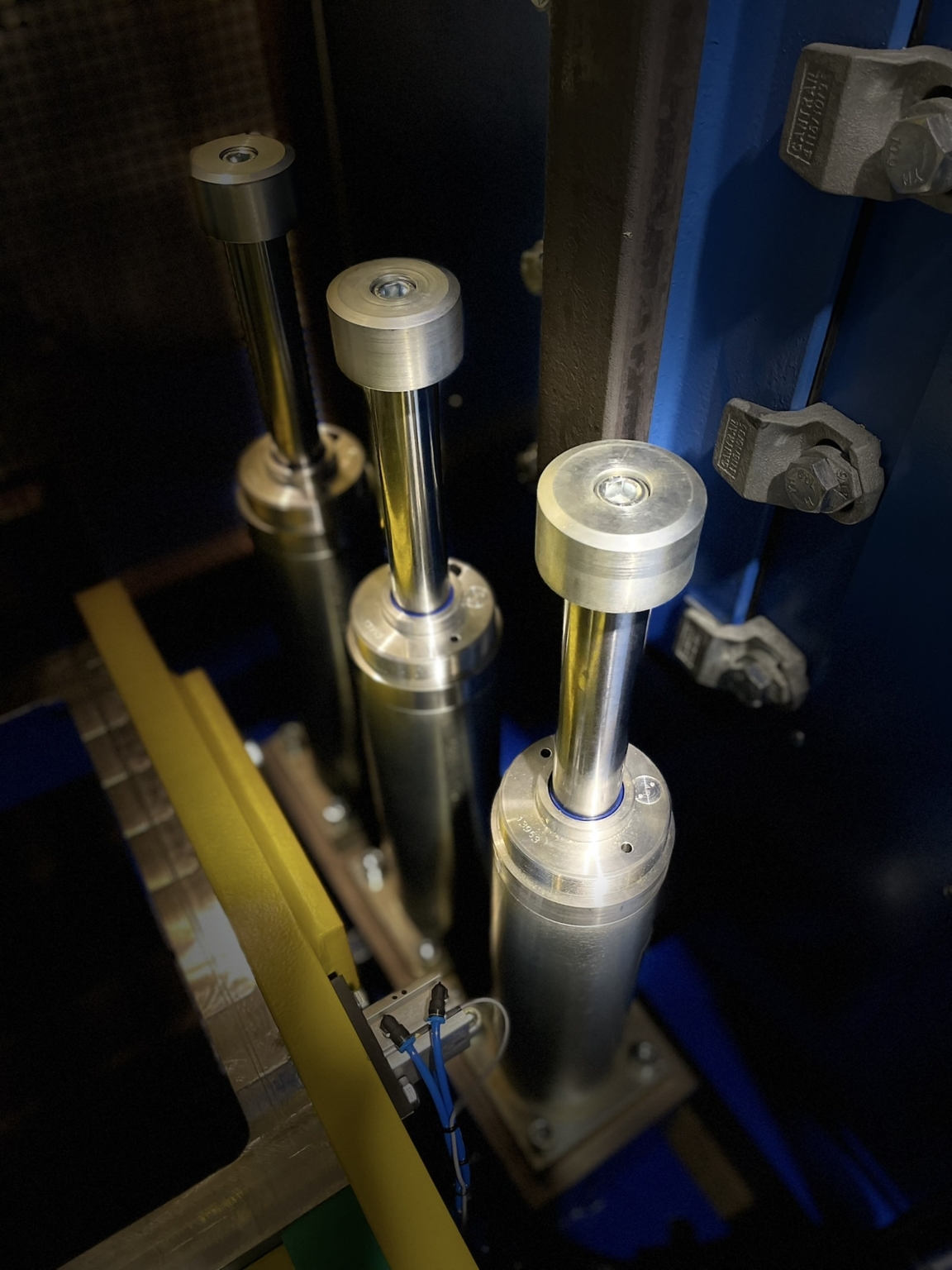

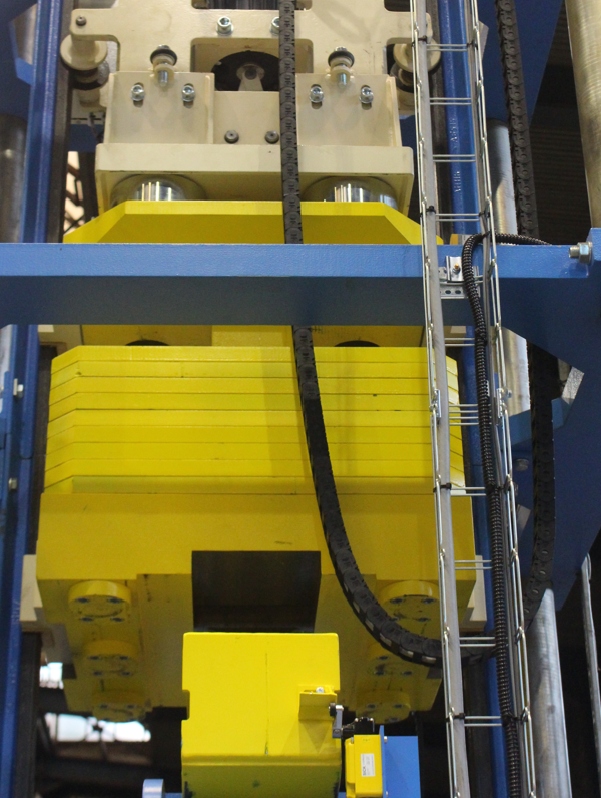

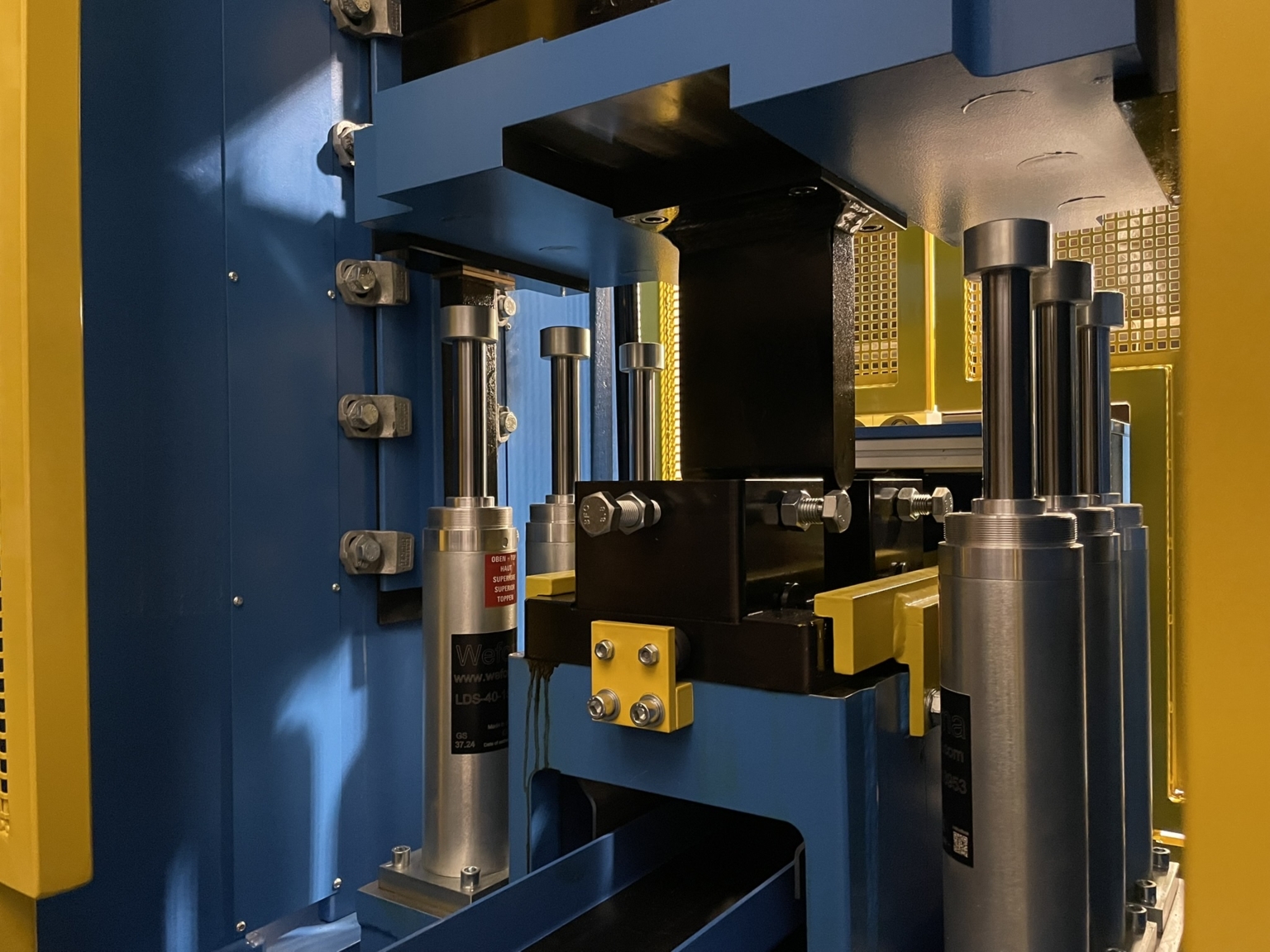

- The unique combination of the magnetic protection system in cooperation with the ELHY electro-hydraulic device enables optimization of the hammer rebound

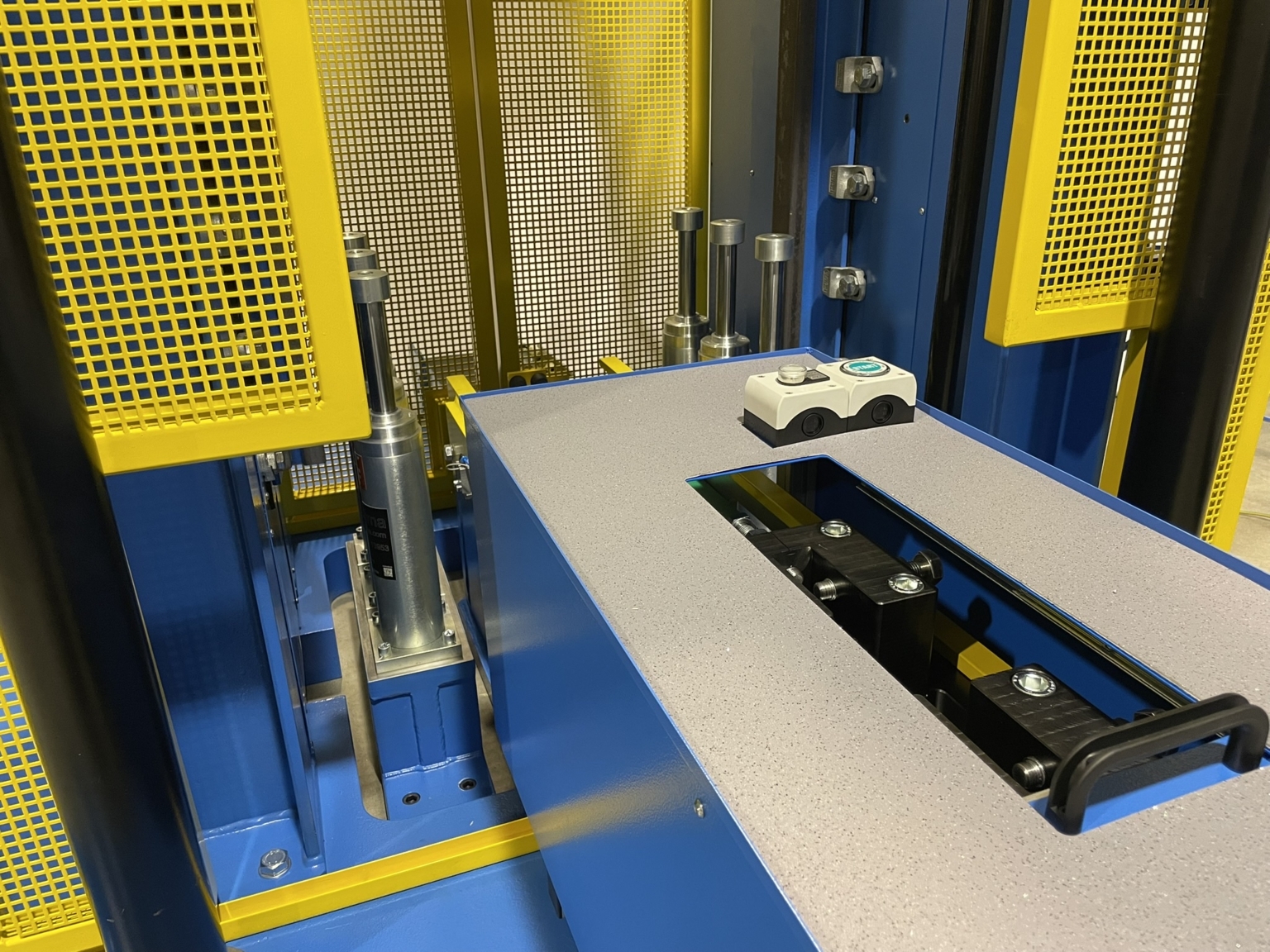

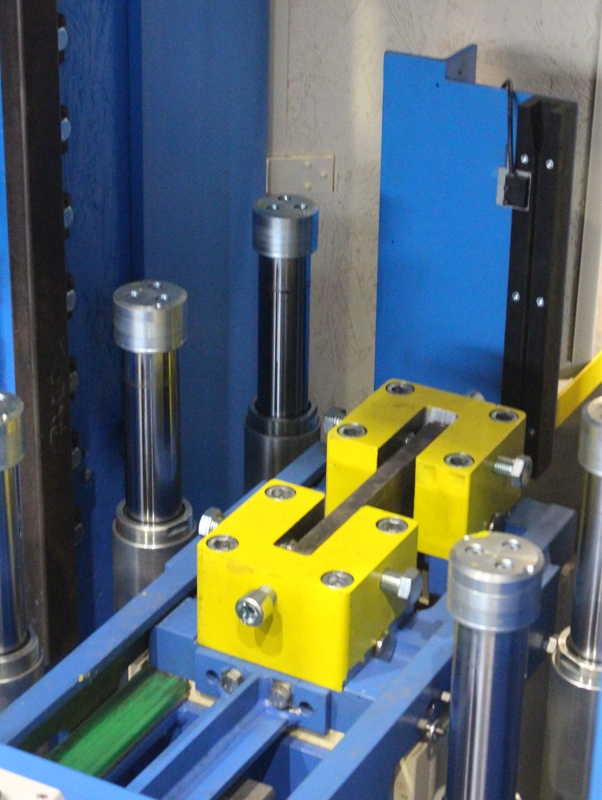

- Automatic introduction of the sample into the test zone by the manipulator, breaking the sample within 10 sec..

- Automatic lifting of the caliper according to the required energy with precise electronic travel to the defined position. Extension with instrumentation with measurement of force and impact path with a measurement speed of 4MHz.

- Automatic identification of instrumented test mandrels working in the accuracy class according to EN ISO 7500-1, ASTM E4 with the possibility of linearization.

- The device meets all the necessary safety requirements, such as DIN 51 333, EN ISO 13489 and other European standards.

- Protective safety cover in the working area of the machine with high safety EN ISO 13849-1 / 2 Calibrated weights by an accredited laboratory according to EN ISO/IEC 17025 – Act 505/1990.

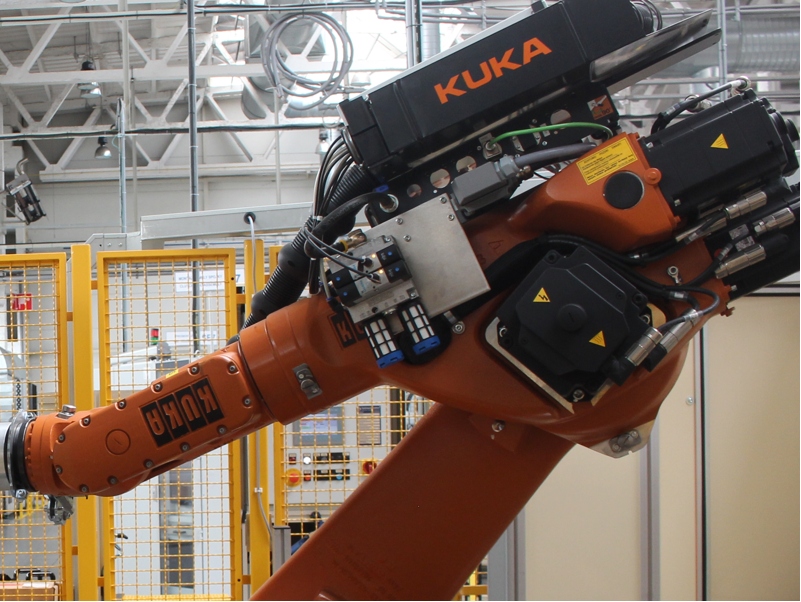

- The possibility of expanding the machine with various mandrels, clamping fixtures, temperature chambers, robotic workplaces…

MEZERA

VIDEOS OF DROP WEIGHT TESTERS DP.3

Impact test on a high-capacity 100,000J machine

Impact testing of test samples according to EN 10274 and ASTM E436 on a high-capacity parachute DP.3 with an impact energy of 100,000J.

Do you have questions about our products?

Feel free to contact our product experts.

We look forward to your interest.

–

MEZERA

We offer technical solutions – WE ARE PROFESSIONALS

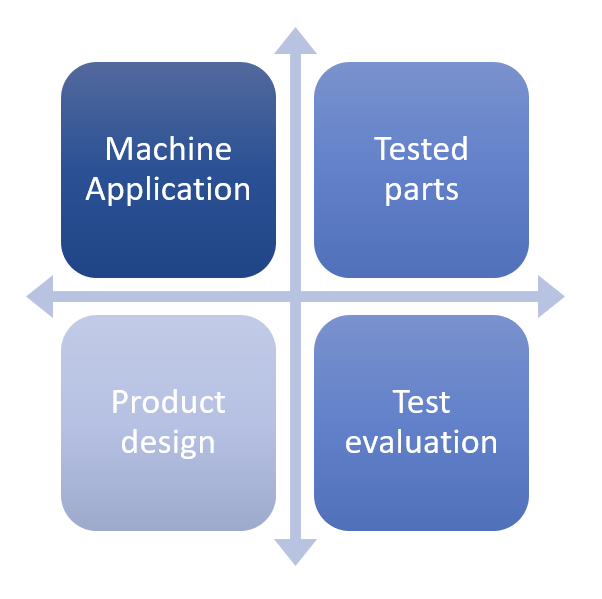

An individual approach to the design of the machine itself and shock devices…

MEZERA

Deploying the machine

It depends on how often you try. Accordingly, the machine can be supplemented or prepared for:

- Manual operation – manual loading and unloading of samples

- Semi-automatic operation – the operator places the samples on the manipulator, which moves into the working space of the machine. Here, it guarantees breaking through the sample within 10 seconds.

- Automatic operation – the operator places the part on the handling table, the manipulator or the robot puts the sample in the cooling bath, after cooling the robot or the manipulator places the sample in the working space of the machine and the sample is punched. As an alternative when taking a sample from the working space of the machine, a robot with a camera can be used, which will take broken samples from the working space of the machine. Breaking through the sample within 10 seconds is a matter of course.

It only depends on you which option you choose.

It is also very important how important impact energy and impact speed are to you. These parameters determine how the machine will look.

Tested parts

The DP.3 series of high-capacity drop machiness is ideal for testing the following parts:

- normalized samples

- rails according to GOST R 51685-2013

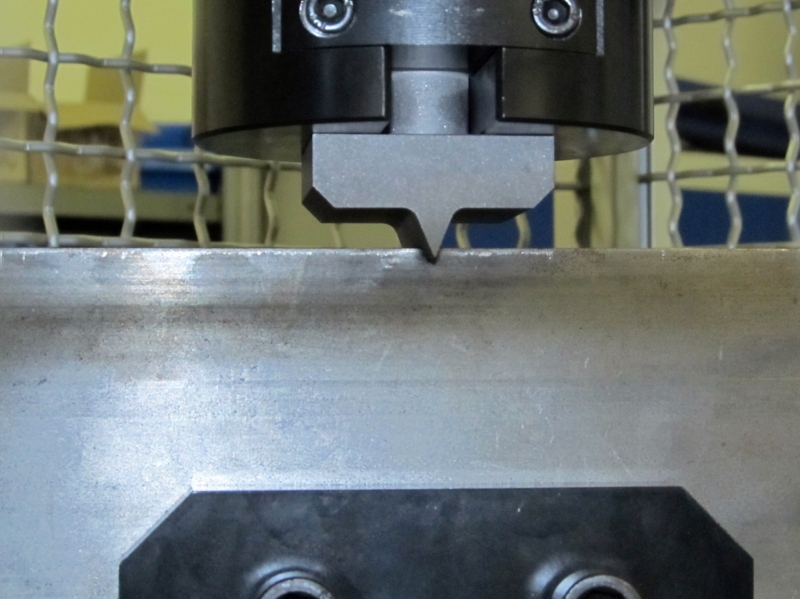

Design of test preparations

Every part that is tested on high-capacity parachute machines must have 100% test fixtures that have:

- High accuracy

- Alignment

- Hardness

- Tenacity Mechanical resistance

All fixtures are designed in 3D CAD INVERTOR with detailed diagnostics using the FEM method, manufactured and then subjected to demanding testing in our test laboratory. We guarantee the result, we are professionals.

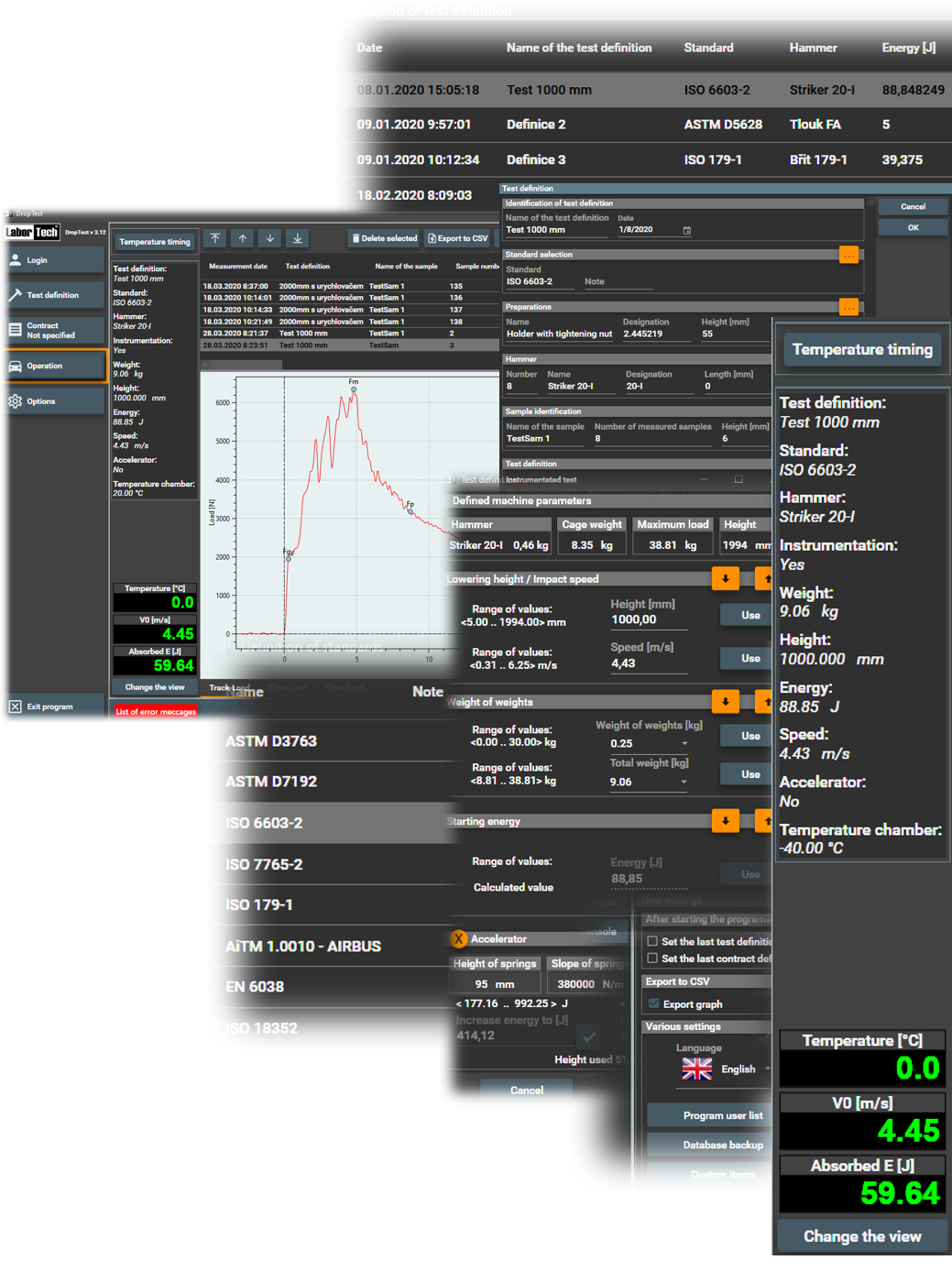

Exam results

The integrated DROPTest-S software is an intuitive software that is part of all parachutes of the DPFest series from LABORTECH. This software allows you to basically operate the impact device with the exact definition of the test according to regulations and standards EN, ISO, DIN, ASTM, GOST, monitors the calibration modes, ensures the collection and transfer of measured data to a superior PC with DROPTest- BASIC software, etc.

DROPTest – BASIC – intelligent, intuitive and powerful software, which is an add-on part of all parachutes of the DPFest series from LABORTECH. We will help you to increase the productivity and quality of testing in your test rooms and testing laboratories. You can streamline, refine, and speed up your test execution and customize your testing environment to make it easy for operators to measure torque and angle or perform rotational fatigue tests while stressing samples and whole products.

- Intelligent, intuitive and powerful software designed for fast and rational vertical impact tests

- An unlimited number of test methods, a modular system of libraries designed for standardized tests, easy orientation in pre-selected definitions with visualization of fixtures – supports and hammers, etc.

Tell yourself what you want and what you expect from the software and we will fulfill it for you.

MEZERA

Our specialists are able to custom design and manufacture a machine or automated system with a high degree of quality and uniqueness. In the case of fixture design, optimization often starts with details and in 3D STEP formats or DWF viewers. When developing LABORTECH products, we place great emphasis on the quality, design and affordability of our products. When designing machines and systems, we pay attention to the minimum environmental burden and EKODESIGN in accordance with the ČSN EN ISO 14001:2016 standard. We verify the accuracy, reliability, durability and mechanical resistance of our machines in the test and calibration center.

MEZERA

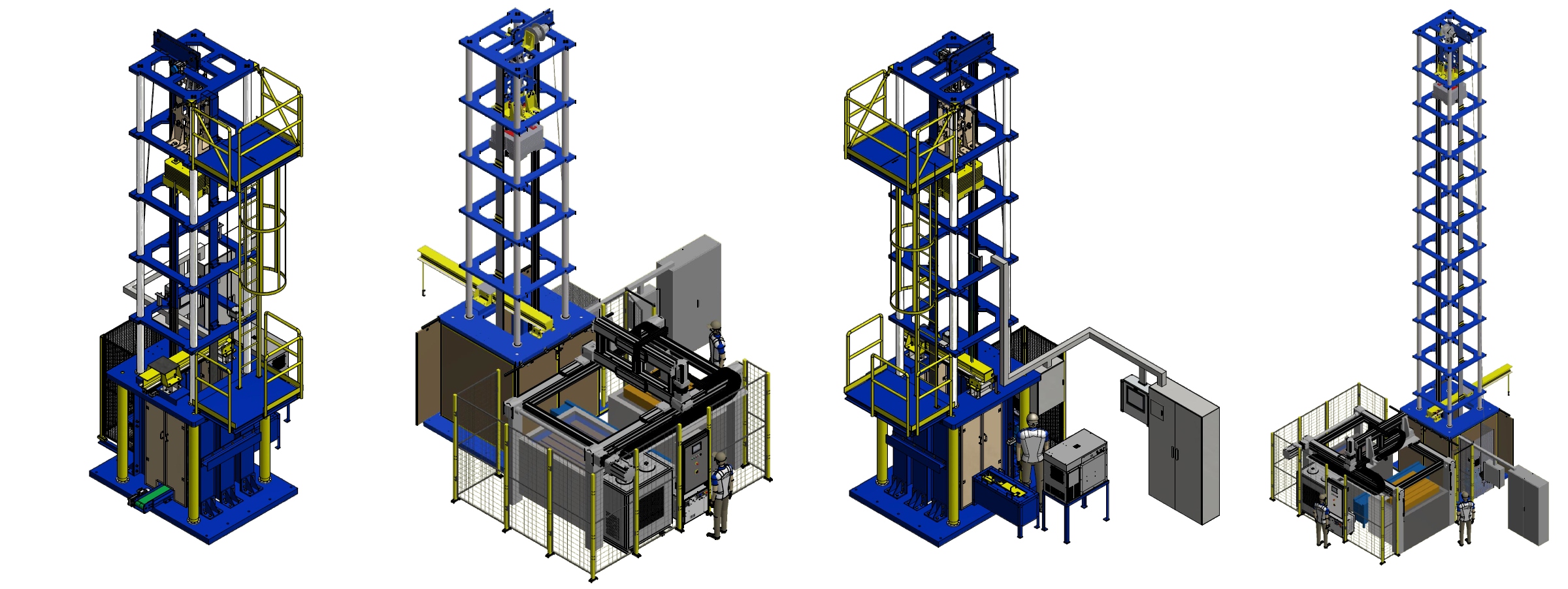

MODULAR SOLUTION OF HIGH CAPACITY IMPACT MACHINES DP.3

Customer solutions – uniqueness down to the last detail, because the detail matters..

MEZERA

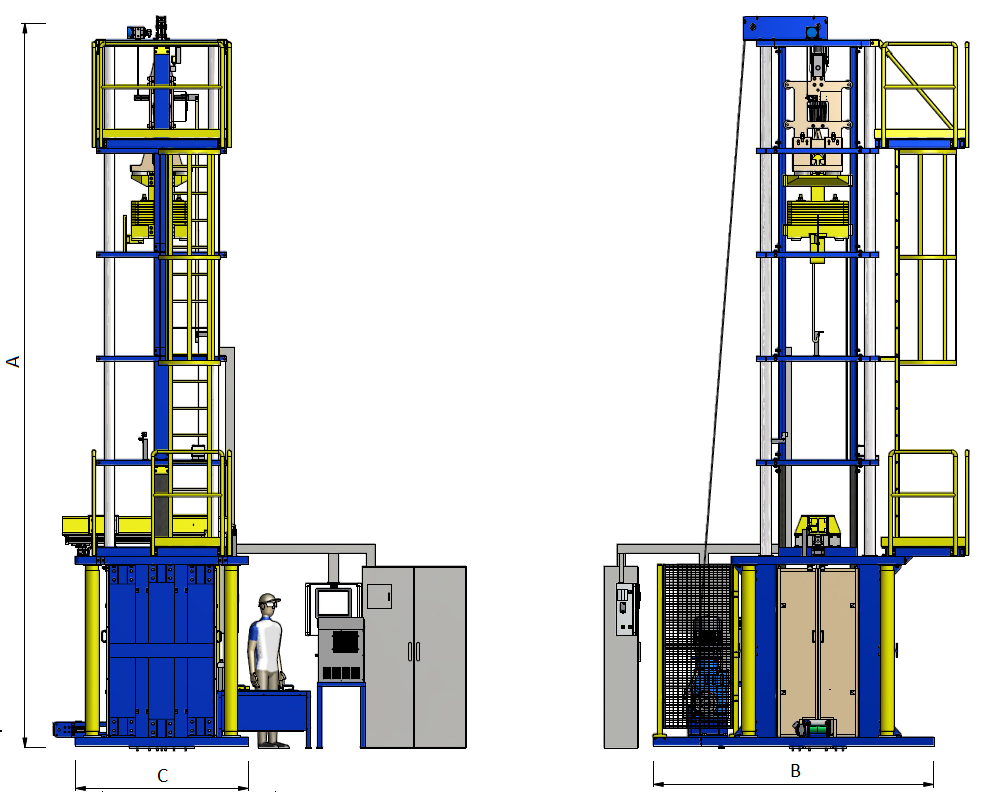

TABLE OF TECHNICAL PARAMETERS of the DP.3 series up to 60,000J

- Technical data

- Product code

- Measuring range

- Impact speed

- Drop height range

- Position repeatability

- Range of weights used

- Machine weight

- Color combination

- Machine height – A

- Machine width – B

- Machine depth – C

- Power voltage

- Machine power

- Units

- –

- J

- m/s

- mm

- mm

- kg

- kg

- RAL

- mm

- mm

- mm

- V / Hz

- kVA

- DPFest 20k

- 1.04031021

- 118 – 20 000

- 1,98 – 7,03

- 200 – 2500

- 1

- 60 – 810

- 6120

- 1015, 5015, 1021

- 4860

- 1200

- 1230

- 3×400 / 50

- 8,5

- DPFest 40k

- 1.04031121

- 118 – 40 000

- 1,98 – 9,01

- 200 – 4150

- 1

- 60 – 990

- 6840

- 1015, 5015, 1021

- 6950

- 1200

- 1230

- 3×400 / 50

- 8,5

- DPFest 60k

- 1.04030017

- 118 – 60 000

- 1,98 – 9,87

- 200 – 4970

- 1

- 60 – 1230

- 10800

- 1015, 5015, 1021

- 8560

- 1800

- 1800

- 3×400 / 50

- 12

TABLE OF TECHNICAL PARAMETERS of the DP.3 series – 80,000 to 120,000J

- Technical data

- Product code

- Measuring range

- Impact speed

- Drop height range

- Position repeatability

- Range of weights used

- Machine weight

- Color combination

- Machine height – A

- Machine width – B

- Machine depth – C

- Power voltage

- Machine power

- Units

- –

- J

- m/s

- mm

- mm

- kg

- kg

- RAL

- mm

- mm

- mm

- V / Hz

- kVA

- DPFest 80k

- 1.04030117

- 294 – 80 000

- 2,42 – 9,87

- 300 – 4970

- 1

- 100 – 1640

- 14200

- 1015, 5015, 1021

- 8560

- 1800

- 1800

- 3×400 / 50

- 12

- DPFest 100k

- 1.04030217

- 294 – 100 000

- 2,42 – 9,87

- 300 – 4970

- 1

- 100 – 2060

- 16200

- 1015, 5015, 1021

- 8560

- 1800

- 1800

- 3×400 / 50

- 12

- DPFest 120k

- 1.04030519

- 294 – 120 000

- 2,42 – 9,87

- 300 – 4970

- 1

- 100 – 2460

- 18800

- 1015, 5015, 1021

- 8560

- 1800

- 1800

- 3×400 / 50

- 12

MEZERA

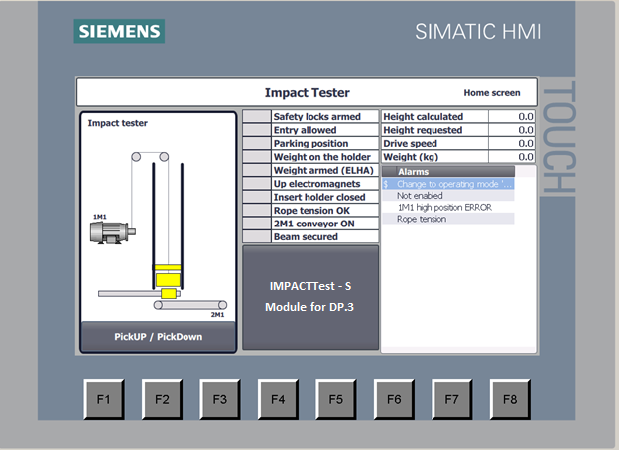

BASIC CONTROL SYSTEM

Intuitive parachute control system with the highest level of safety and DROPTest-S software

MEZERA

- Users and authorization – Top-level security – allows the test facility manager to configure permition to use the machine, grant full permition and, if necessary, restrict access using reader attendance cards.

- Integrated safety alert – IMPACT-S is a fully enclosed system with accurate fault monitoring. Each error has 3 states: I (incoming), A (acknowledgment) and O (outgoing). That is, when the error appeared, when it acknowledged and when it ceased to be active.

- UPC as standard – thanks to integrated source security, your results are always safely saved even in the event of an unplanned power failure or for other reasons.

- The integrated DROPTest-S software is an intuitive software that is part of all DPFest machines from LABORTECH. This software allows you to operate the shock device with precise test definition according to regulations and standards EN, ISO, DIN, ASTM, GOST, Airbus AITM and Boeing BSS, monitors calibration modes, provides collection and transmission of measured data to the master PC with IMPACTTest-BASIC software etc.