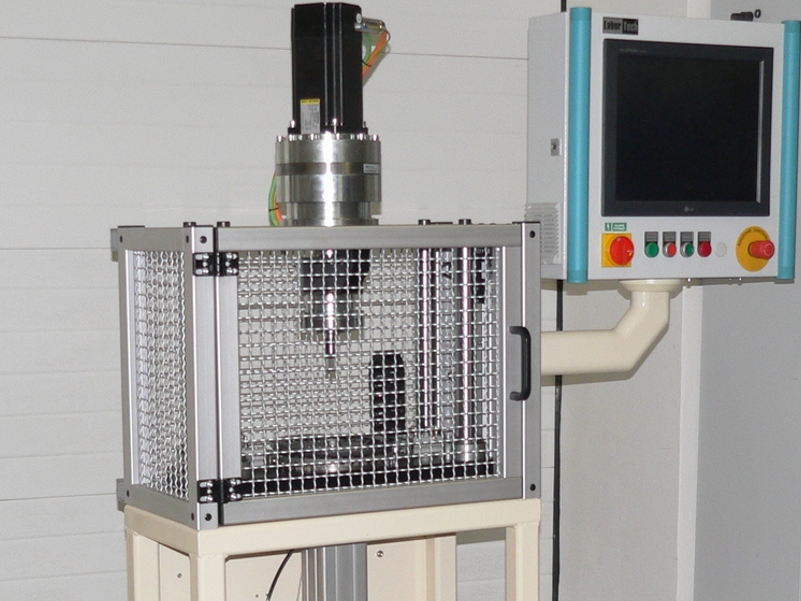

KM.1 – Vertical angular torsion series up to 5000Nm

Electromechanical vertical torsion testing machines of the KM.1 series in a stand design up to 5000 Nm, which are primarily intended for measuring torque and friction torque, including the angle of rotation of both parts and entire products with the possibility of performing these tests over “0”. research and development, routine quality control in laboratories and operations, but also for assembly and testing semi-automatic lines. LABORTECH machines are characterized by very high rigidity of the test frame, speed and accuracy of measurement in semi-automatic mode.

Download:

Download:

MEZERA

General key features of the KM.1 series

- Robust vertical stand modular design with mechanical resistance and durability.

- Abnormally high rigidity and mechanical resistance of the machine combined with ergonomics at a high level.

- Integrated torsion mechanism at the top or bottom of the machine – depending on application.

- Quiet and precise AC servo drive with cycloidal gearbox with low noise and high angular resolution and max. Angular rotation ± 180 °.

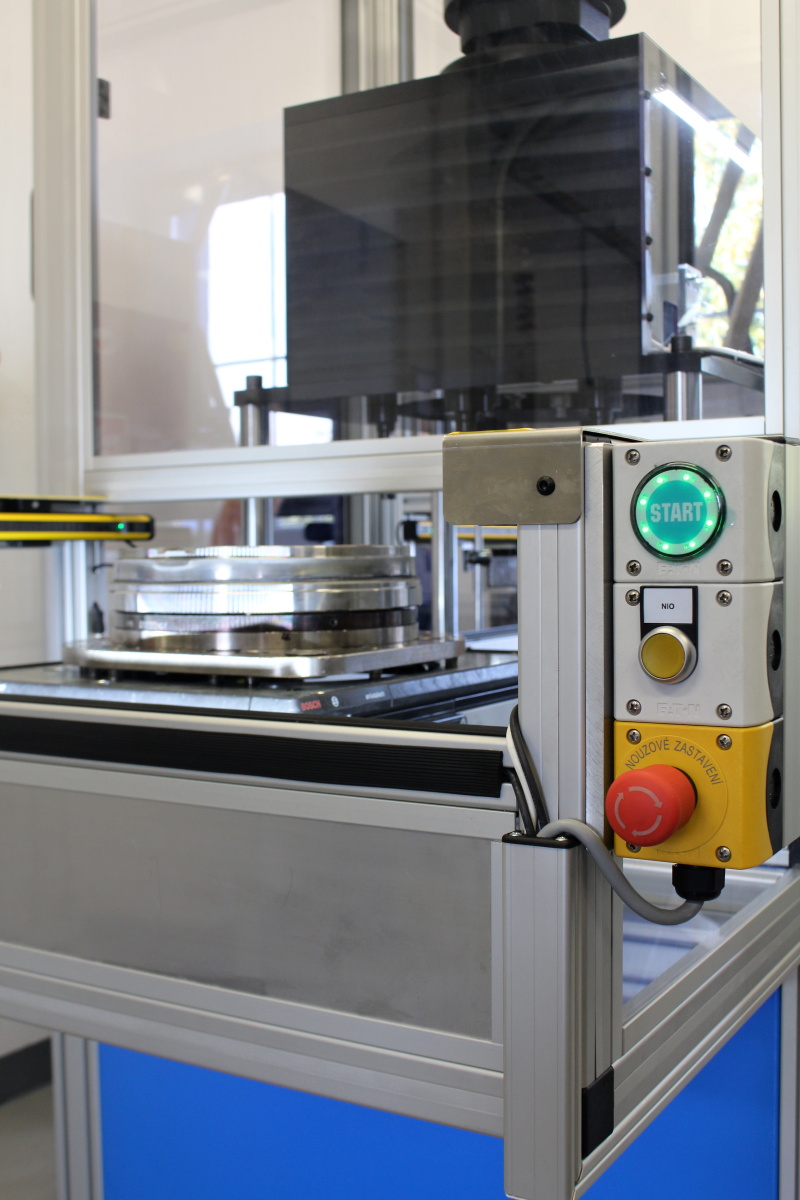

- The KM series machines comply with all the above-mentioned EC directives on machinery and equipment and work in accordance with the new safety functions according to EN ISO 13850-SIL 1 / PL.

- Torque sensors working in accuracy class according to EN ISO 7500-1, ASTM E4 incl. linearization.

- The machine is controlled by measuring and control electronics of the EDCi series with a sampling frequency of 2.5 or 10 kHz. Analog signal resolution level ± 250,000 divisions (20 ms).

- Protective safety covers made of ITEM profiles and polycarbonate with high safety EN ISO 13849-1 / 2 or safety barrier.

- Possibility to control and set the machine using a touch LCD monitor.

- Complete evaluation and test control software for testing materials in torsion – KMTest.

- Wide range of accessories – test mandrels, fixtures, holders, chucks, etc.

MEZERA

VIDEOS on KMTest testing machines of the KM.1 series

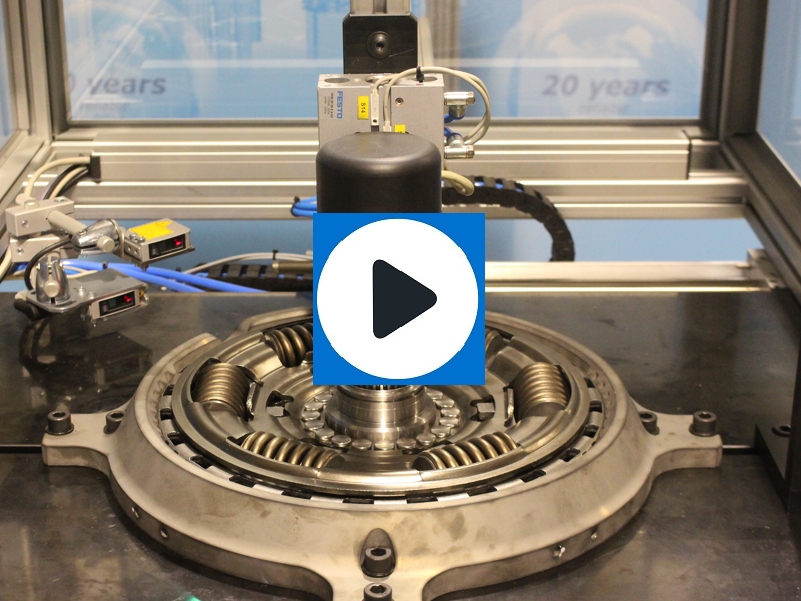

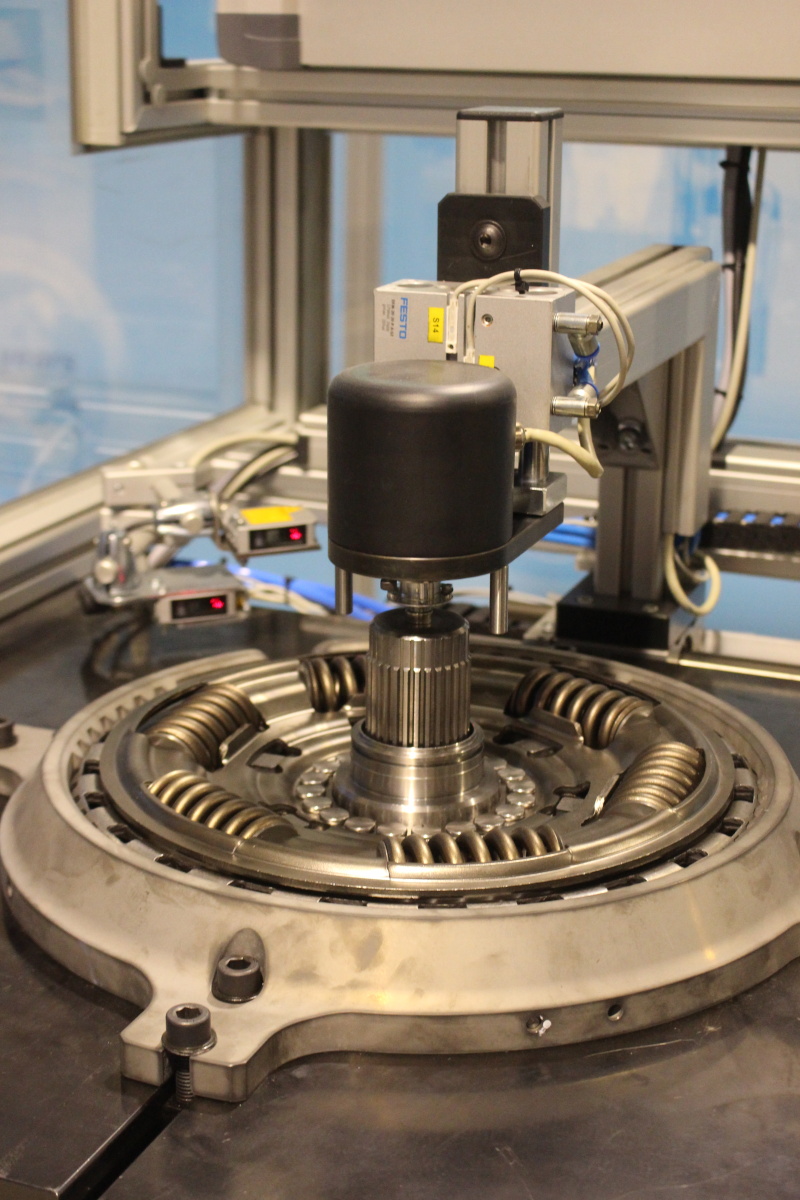

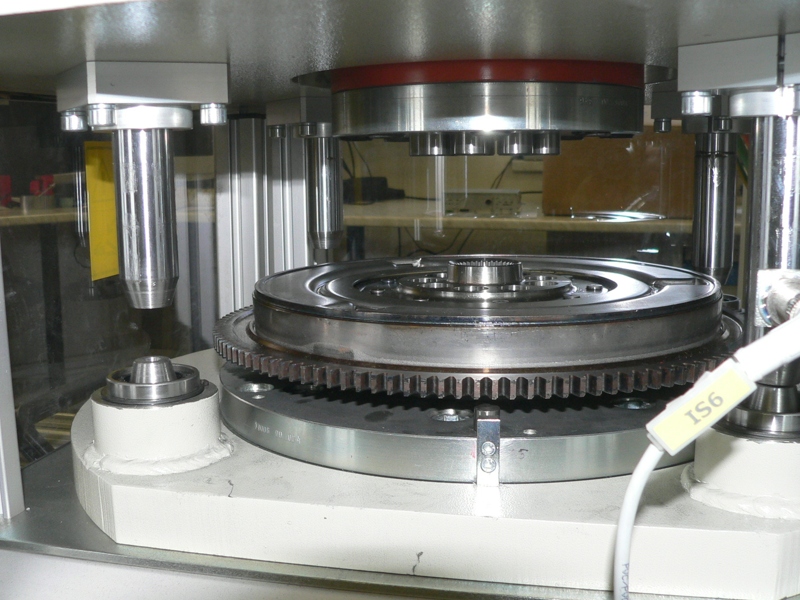

Comprehensive testing of two-state flywheels

Evaluation of friction, end torque and angle in tension and pressure, definition of tolerance bands, max. Torsional moment ± 2000Nm, angle of rotation ± 20 °

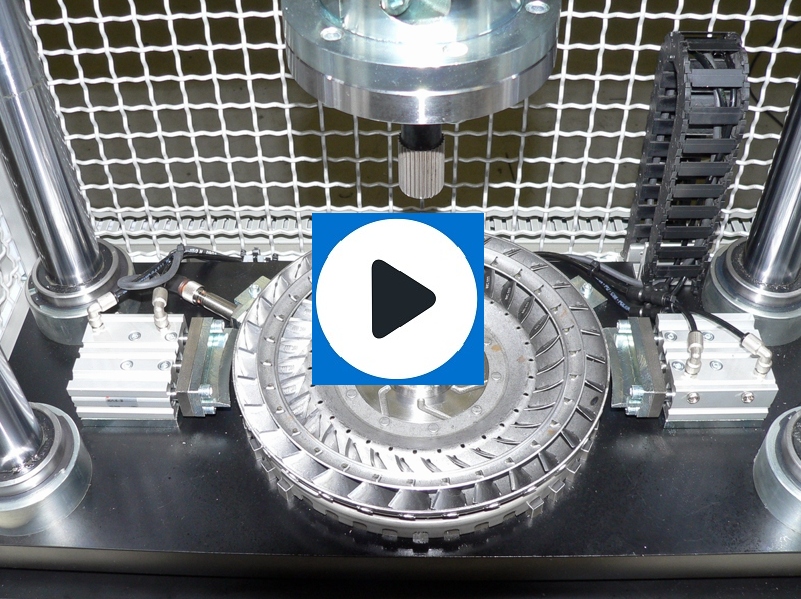

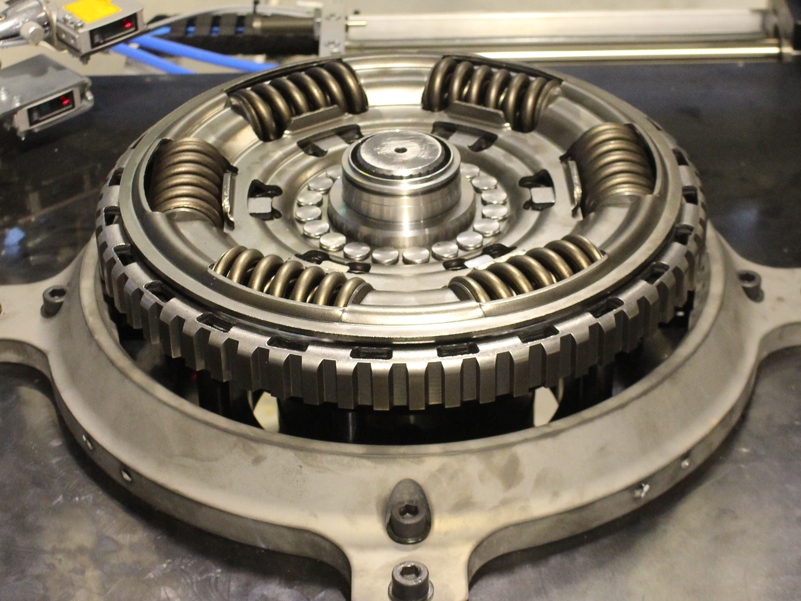

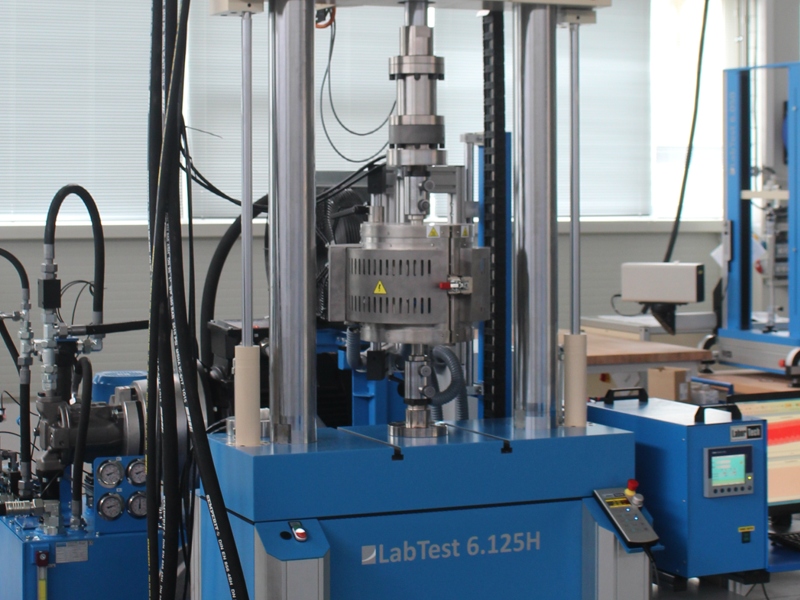

Comprehensive testing of torsion dampers of passenger cars

Friction and torque friction evaluation, damper rotation angle measurement, max. Torsional torque ± 5000Nm, rotation angle ± 20 °

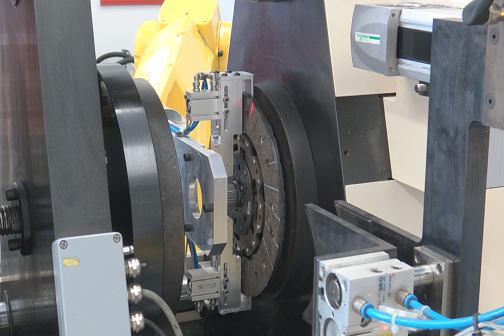

Measurement of the torsional characteristics of the PKW lamella

Vertical angular torsion testing machine for measuring the rotation of the slats, in front of the damper and the main damper, max. Torque ± 500Nm and with angular rotation ± 150 °

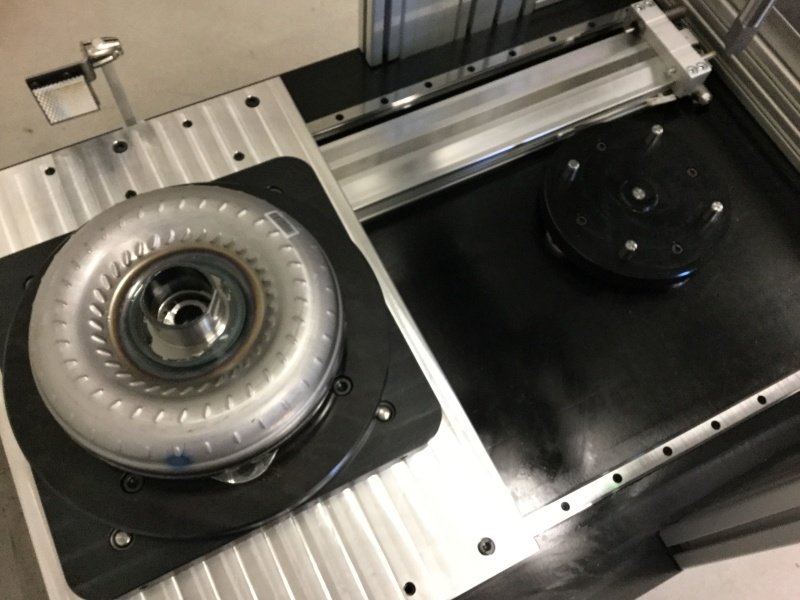

Measurement of torsion characteristics of PKW converter

Vertical angular torsion testing machine with a maximum torsional torque of ± 500 Nm and with an angular rotation of ± 25 °.

MEZERA

Do you have questions about our products?

Feel free to contact our product experts.

We look forward to your interest.

–

MEZERA

We offer technical solutions – WE ARE PROFESSIONALS

Individual approach to the design of fixtures and the machine itself …

MEZERA

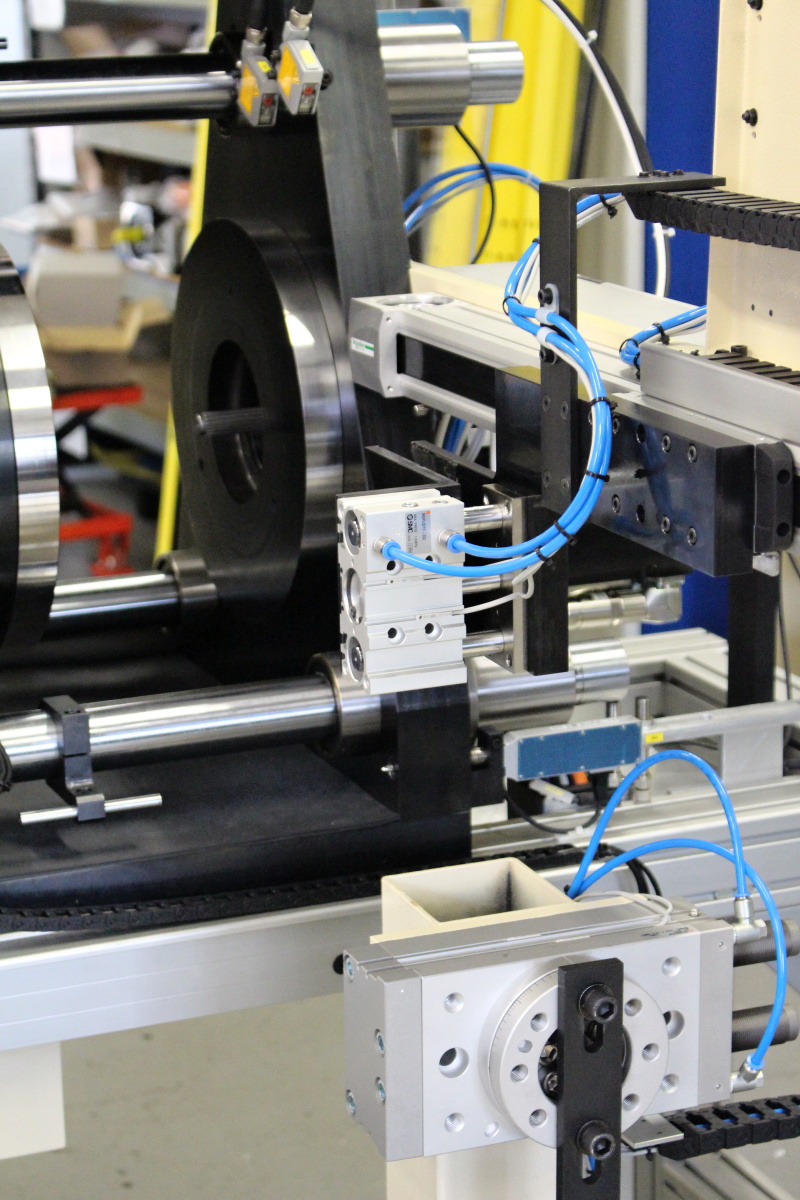

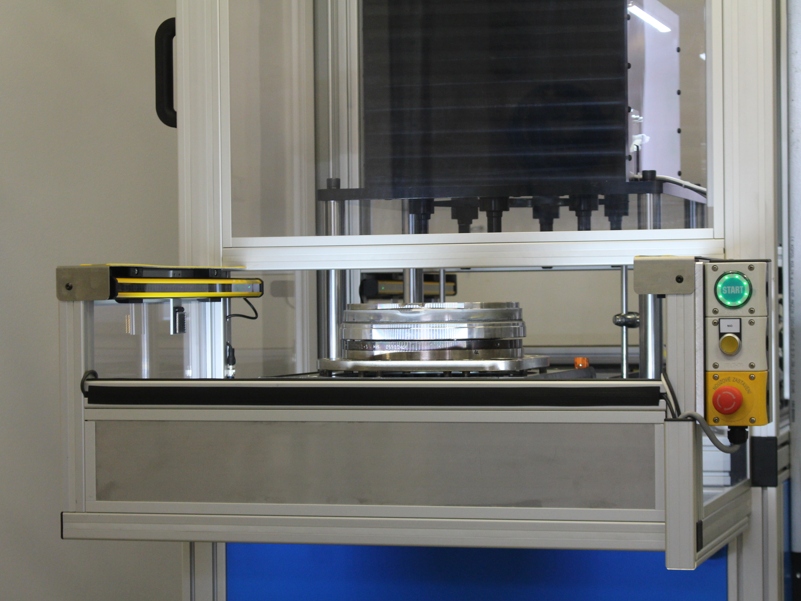

Machine application

It depends on where the machine will be deployed – test room, research facility or operation. Accordingly, the machine can be supplemented or prepared for:

- Manual operation – manual loading and unloading

- Semi-automatic operation – the operator establishes, after evaluation the part is removed by a robot, manipulator, etc.

- Automatic operation – the part loads and unloads the manipulator, robot, etc.

Provide a inputs and let us work. We will fulfill your ideas.

Tested parts

The vertical angular torsion series KM.1 is ideal for static testing of the following parts:

- Torsion dampers

- Two-state flywheels

- Lamellae for all types of personal couplings

- Medical technology products

- Fasteners and connectors,

- Engine drive shafts,

- Motor bearings, etc.

Give us a drawing of the tested part and we will design everything for you.

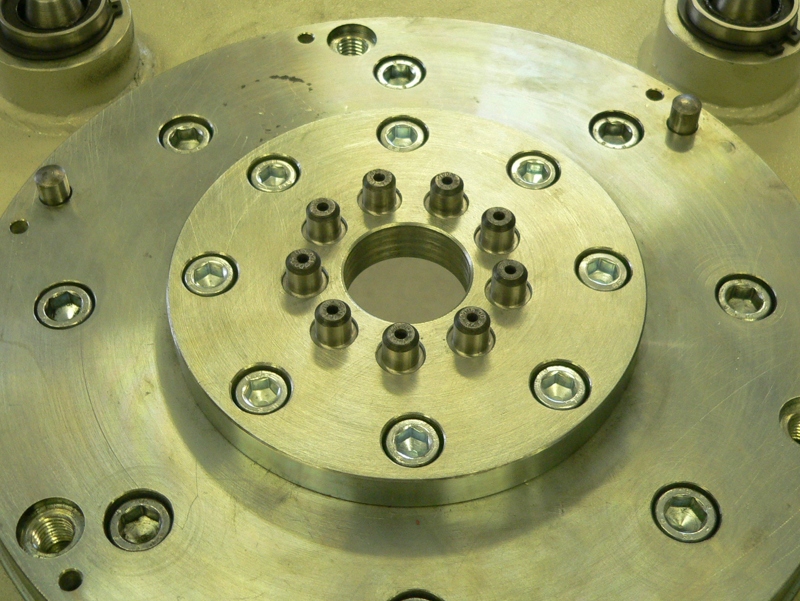

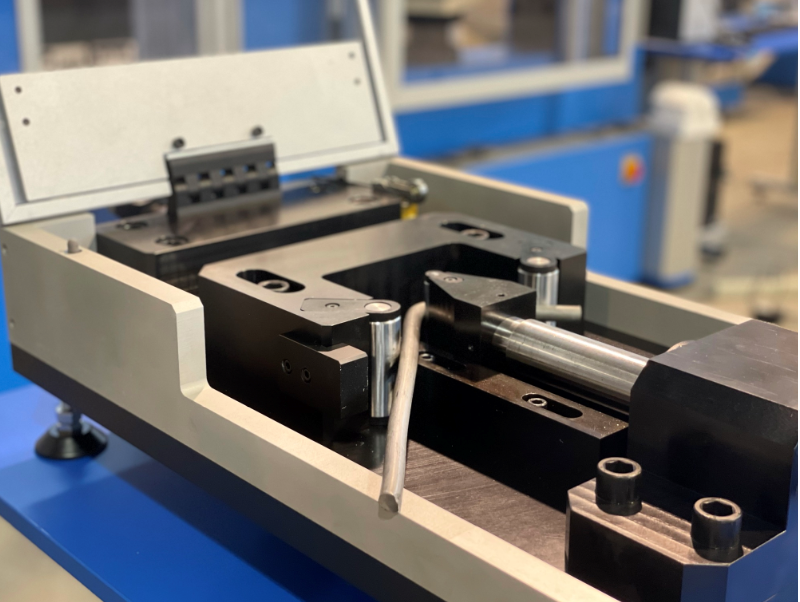

Product design

Each part tested on vertical torsion machines must have 100% test fixtures that have:

- High accuracy

- Concentricity

- Hardness

- Toughness

- Mechanical resistance

All fixtures are constructed in a 3D CAD INVERTOR with detailed diagnostics using the FEM method, manufactured and subsequently subjected to demanding testing in our testing laboratory. We guarantee the result, we are professionals.

Test evaluation

KMTest – BASIC – intelligent, intuitive and powerful software, for manual, semi-automatic or automatic operation with modules:

- KM Test – A module designed for measuring torque and friction torque, including the angle of rotation.

- KM Test – R module designed for measuring torque at different or constant speeds

- We will help you increase the productivity and quality of testing in your test rooms and testing laboratories.

- You can streamline, refine, and speed up the performance of your tests and adapt your testing environment to make it easy for operators to measure torque and angle or perform torsional fatigue tests depending on the number of revolutions of samples and entire products.

Say what you want and what you expect from the software and we will do it for you.

Our specialists are able to custom design and manufacture a machine or automated system with a high degree of quality and uniqueness. When designing fixtures, optimization often begins with details and in 3D STEP formats or DWF viewers. When developing LABORTECH products, we place great emphasis on the quality, design and affordability of our products. In the design of machines and systems, we pay attention to the minimum environmental impact and ECODESIGN in accordance with the standard ČSN EN ISO 14001: 2016. We verify the accuracy, reliability, durability and mechanical resistance of our machines in a test and calibration center.

MEZERA

KMTest – BASIC software

Intuitive software for measuring torque, angle and torsional fatigue tests

KMTest – BASIC – intelligent, intuitive and powerful software that will help you increase productivity and quality of testing in your test rooms and testing laboratories. You can streamline , refine, and accelerate your testing and adapt your testing environment to make it easy for operators to measure quadrant I and II quadrants and angles, or perform torsional fatigue tests depending on sample stresses and entire standards-supported products. EN, ISO, DIN, ASTM and GOST.