CHKTest – Pendulum Impact Testers for metal samples up to 750J

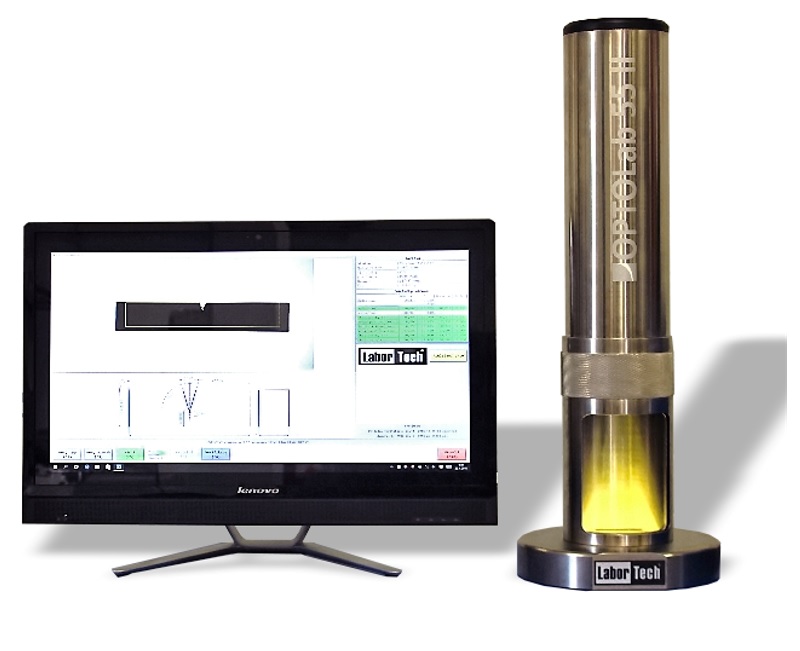

The new series of CHKTest impact pendulum hammers has undergone a thorough upgrade and is part of the so-called NEW Edition 30. This edition is ready to celebrate the 30th anniversary of our company and brings not only a new design, but also many fundamental innovations in the construction of the machines and in many details that facilitate work for our customers.

When designing this new range, we focused on providing maximum flexibility and efficiency. Impact hammers from the LABORTECH company are manufactured modularly in several variants, which can be easily combined according to the needs of laboratories to ensure quality and research and development. This approach allows our customers to optimize their testing processes and achieve the best results.

Below you will find a list of all the innovations that the new CHKTest series of impact hammers have undergone. We believe you will appreciate our efforts to continuously improve our products and would be happy if you consider us when choosing your test equipment.

Download:

Download:

MEZERA

KEY FEATURES OF THE CHKTest SERIES

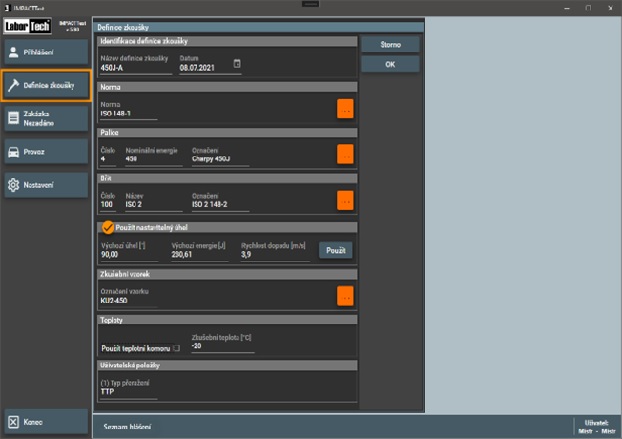

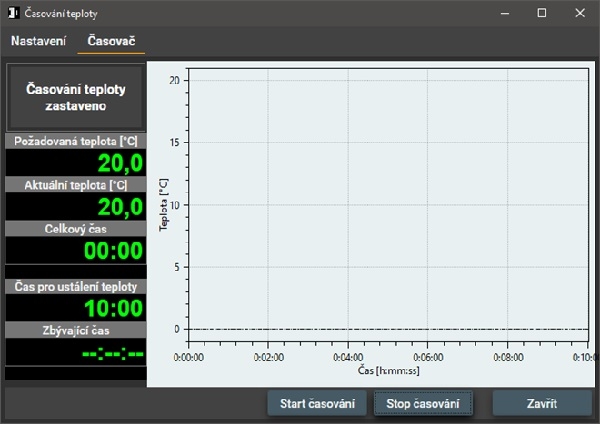

- Use of impact pendulum hammers in accordance with the standards ČSN EN ISO 148-1, ČSN EN ISO 14556, ASTM E23, ASTM E 2298, GOST 9454-78, BS131-1, ZF 15-53, ČSN EN ISO 148-2, ČSN EN ISO 11343 and other company standards.

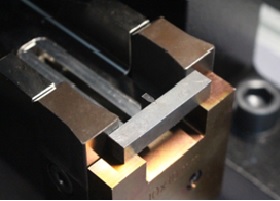

- Test methods: Charpy, Izod, Brugger, tensile impact tests of metal samples.

- Extension of the machine by: INSTRUMENTATION, ANGLE ADJUSTMENT and ROBOTIZATION.

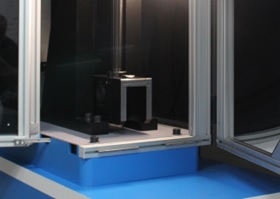

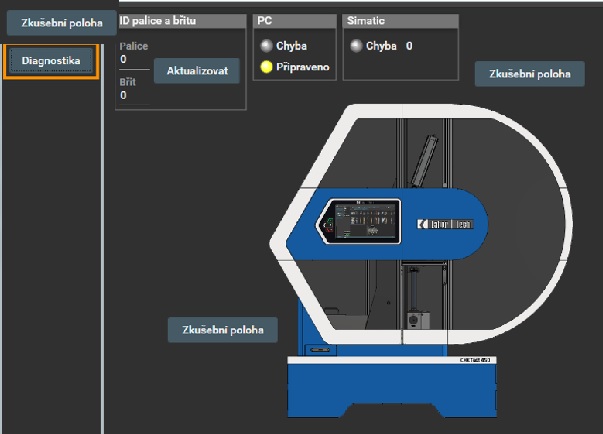

- Centrally ergonomically located control elements ensuring simple operation and testing, including indication of the status of individual processes

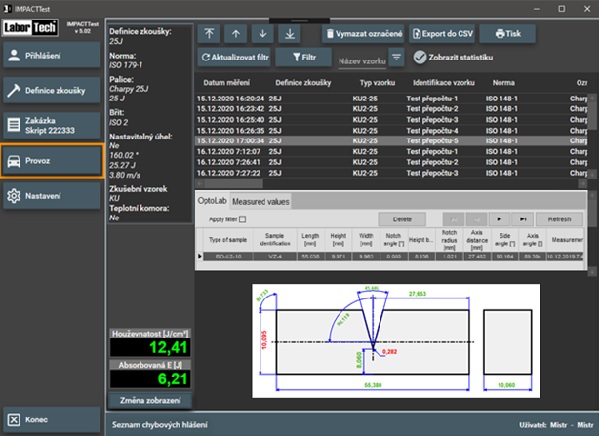

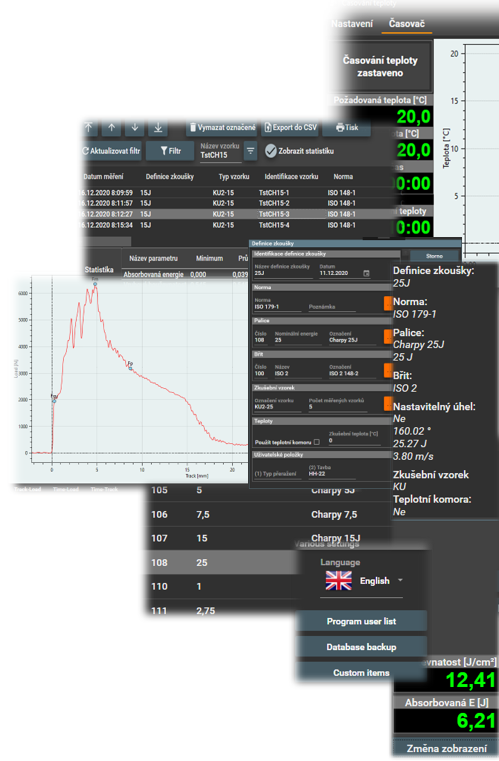

- Compact control of the machine via an integrated 21.5″ touch LCD monitor with the possibility of rotation.

- Automatic arm lift by AC motor with steering.

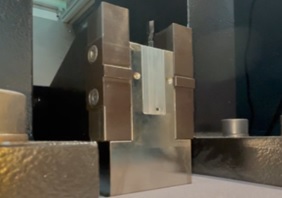

- New automatic central sample centering with damage protection at the base of the machine.

- Incremental sensor with high resolution up to 262,144 imp per revolution for precise angle measurement.

- New automatic identification of ram and blades in the base of the machine.

- A new type of supports with the possibility of using up to 4 times the service life.

- Protective safety cover with electronic door opening monitoring and high security according to ČSN EN ISO 13849-1, ČSN EN ISO 12100 and ČSN EN ISO 14120 and illumination of the working area of the machine.

- Start the test using the button on the door.

- The possibility of expanding the machine with various accessories.