WOOD – TEST METHODS

Contact

Wood and wood products are used in various forms and combinations depending on the area of use and intended use. As a building material and renewable raw material, wood offers many ecological and economic advantages. Many wood products subject to mechanical testing are used in construction, furniture and general purpose manufacturing.The most common reason for testing wood and wood products is to determine their tensile, compressive and flexural strength.

TESTS IN TENSION

BENDING TESTS

PRESSURE TESTS

SHEAR TESTS

CYCLIC TESTS

IMPACT TESTS

MEZERA

The measured strength of wood and wood material determines whether they are suitable for a specific purpose. A variety of static and dynamic test methods are used for wood products to determine their suitability for a particular application. These methods usually involve simple tensile, compressive and bending tests. For example, in tensile tests, the wood material is placed on a testing machine, and tension is applied to its ends. In compression tests, the wooden products are compressed at both ends, while in bending tests, the load is applied to the center of the specimen.

TEST STANDARDS FOR TIMBER TESTING

The correct choice of standard is essential to ensure consistent and reliable results…

Testing wood is a key element in ensuring its quality, strength and ability to withstand various conditions. There are several standardized test codes that specify procedures and methods for testing wood and wood products. These standards are important for industry, construction and research.

ČSN EN 319

Třískové a vláknité desky. Stanovení pevnosti v tahu kolmo k rovině desky. Více informací…

| VÝBĚR STROJE |

ČSN EN 408+A1

Dřevěné konstrukce – Konstrukční dřevo a lepené lamelové dřevo – Stanovení některých fyzikálních a mechanických vlastností. Více informací…

| VÝBĚR STROJE |

ČSN EN 12512

Dřevěné konstrukce – Zkušební metody – Cyklické zkoušky spojů s mechanickými spojovacími prostředky. Více informací…

| VÝBĚR STROJE |

ČSN EN 789

Dřevěné konstrukce – Zkušební metody – Stanovení mechanických vlastností desek na bázi dřeva… Více informací

| VÝBĚR STROJE |

ČSN EN 310

ISO 21581

Dřevěné konstrukce – Metody zkoušek statického a cyklického bočního zatížení pro smykové stěny. Více informací…

| VÝBĚR STROJE |

ASTM D143-22

ASTM D198-22

Standardní zkušební metody statických zkoušek řeziva v konstrukčních rozměrech. Více informací…

| VÝBĚR STROJE |

EN 314-1:2004

ISO 13061-3:2014

Zkušební metody pro malé čiré vzorky dřeva. Část 3: Stanovení meze pevnosti při statickém ohybu. Více informací…

| VÝBĚR STROJE |

ISO 13061-4:2014

Zkušební metody pro malé čiré vzorky dřeva. Část 3: Stanovení modulu pružnosti při statickém ohybu. Více informací…

| VÝBĚR STROJE |

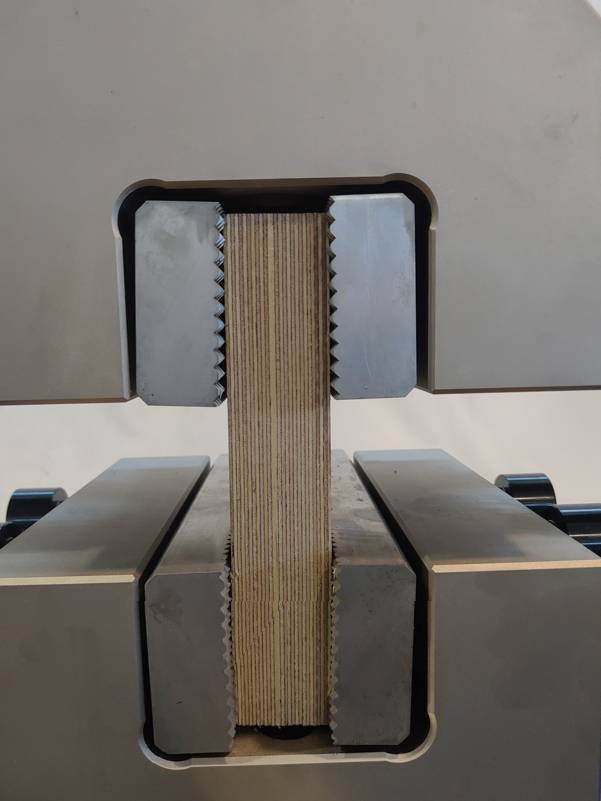

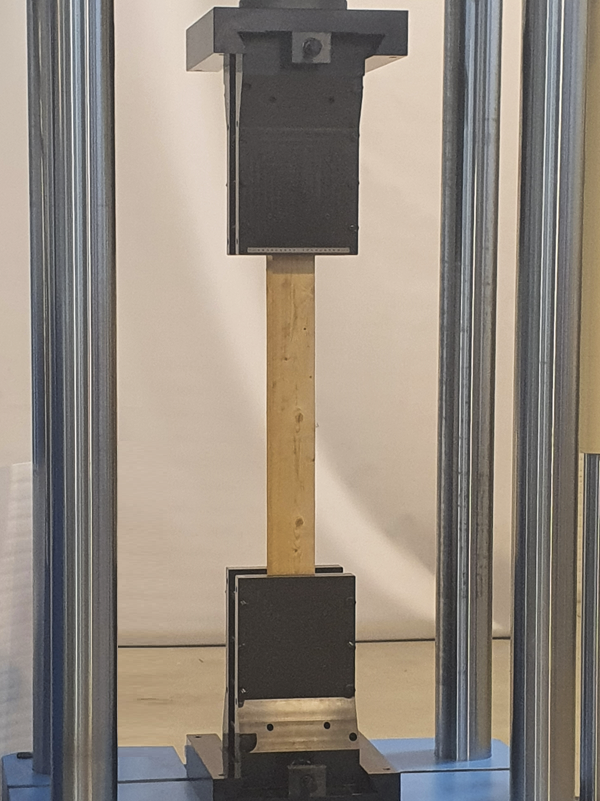

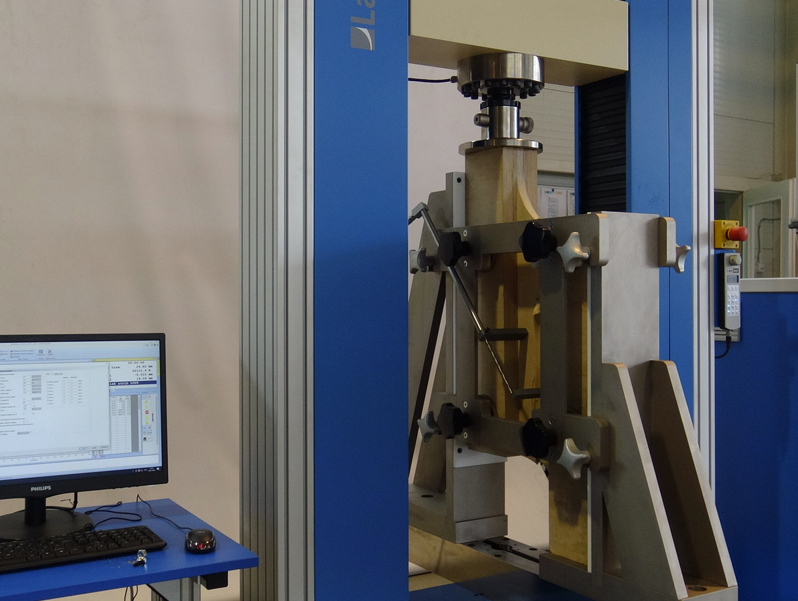

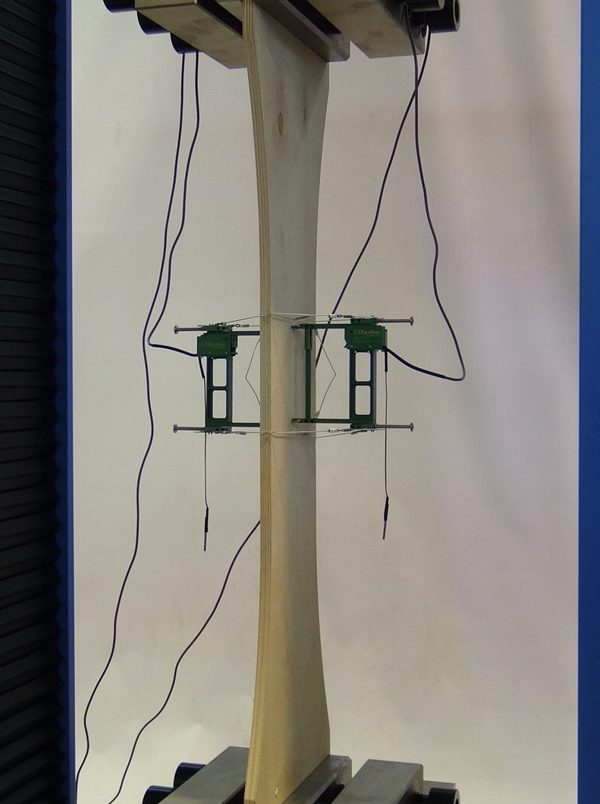

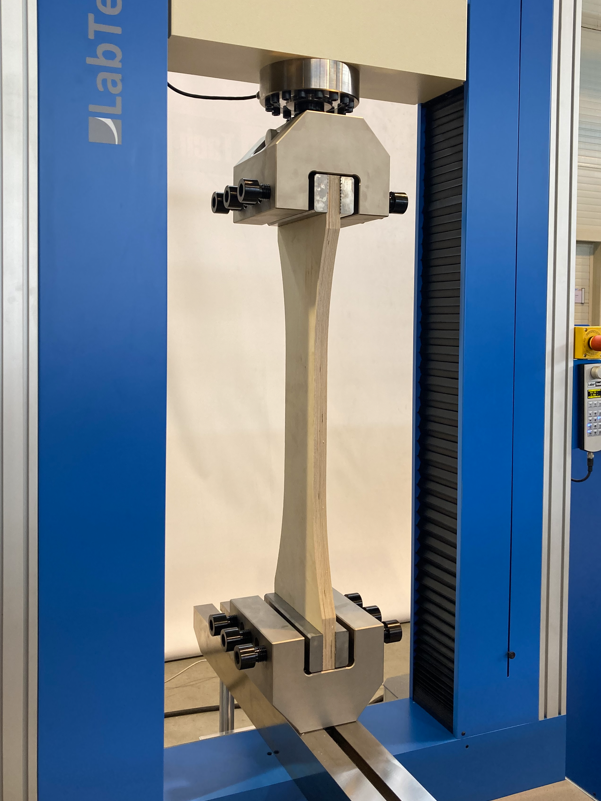

TENSILE TEST OF WOOD

Tensile wood tests represent the basic and key method for assessing the ability of wood to withstand tensile forces. These tests are necessary to understand its mechanical properties and are used in the design and construction of wooden structures in construction, furniture, furniture manufacturing and other industries. Here’s a look at the meaning and process of timber tensile testing.Assessment of material strength: wood tensile tests are designed to determine the strength of a material against tensile forces. During the test, a uniform tensile force is applied to the wood sample, gradually increasing up to the point of failure. This test makes it possible to measure the maximum tensile force that wood can withstand and to determine its yield strength, which is the point at which the material begins to permanently deform.Valuable information for construction: the results of timber tensile tests provide important information for engineers and designers in the design of timber structures. Determining the tensile strength of wood makes it possible to properly dimension supporting elements such as beams, posts, rods and other structural elements. This ensures the safety, stability and long-term durability of wooden structures.Various Factors Affecting Results: The results of wood tensile tests can be affected by various factors such as wood type, humidity, temperature, fiber length and more. Therefore, it is important to perform tests under standardized conditions and take all these factors into account when interpreting the results. Practical applications: Wood tensile tests are an invaluable tool for furniture makers, structural engineers, architects and other professionals working with wood materials. These tests provide important information about the strength and durability of wood, leading to safer and more reliable structures and products.

Tensile tests of wood are an essential tool for assessing its mechanical properties and ability to withstand tensile forces. These tests provide important information for the construction and design of wooden structures and products, which contributes to the safety, stability and long-term durability of the use of wood in various applications.

Recommended testing machines designed for tensile testing of wood

We will be happy to advise you on the right choice of machine…

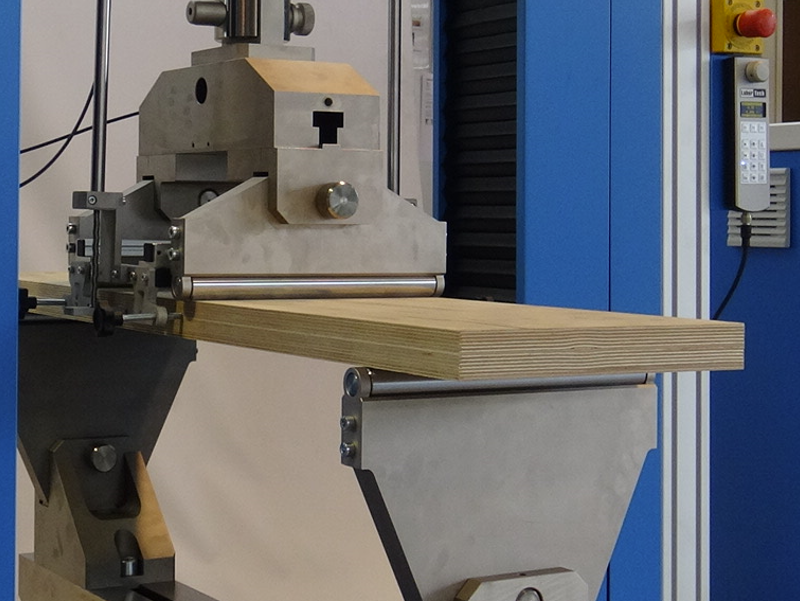

BENDING TEST OF WOOD

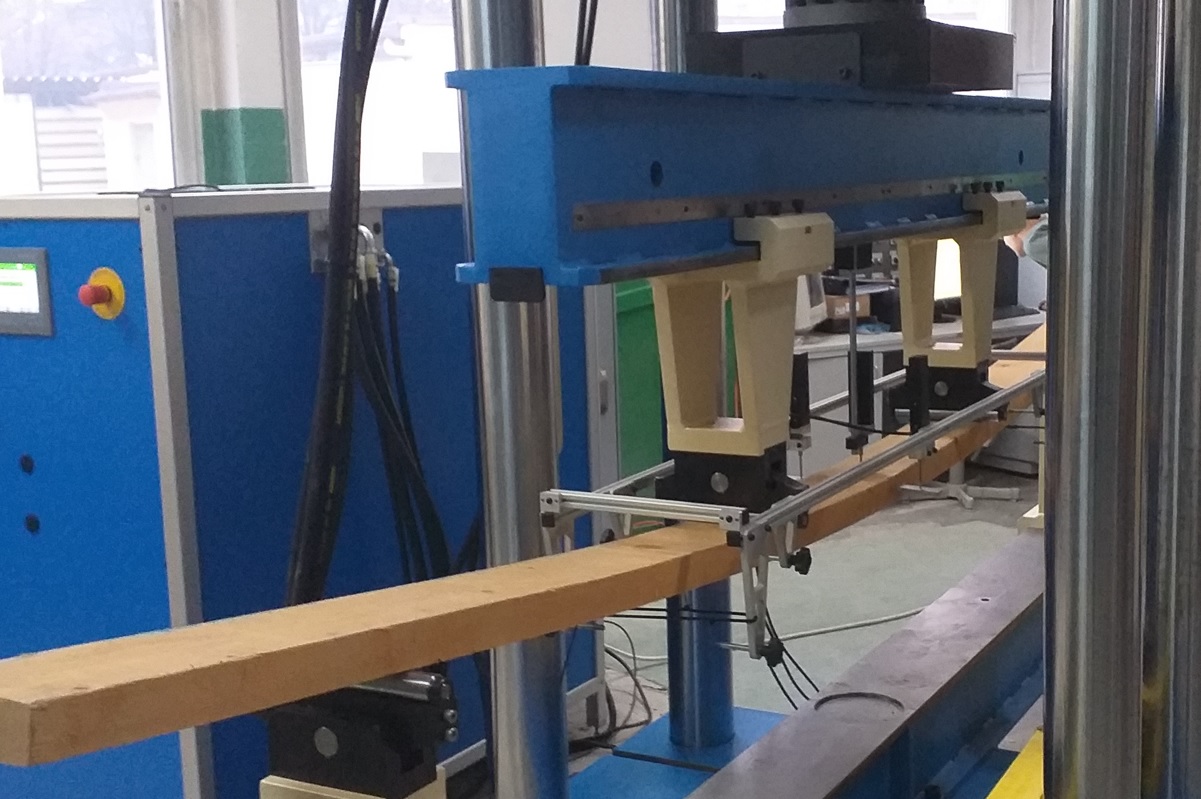

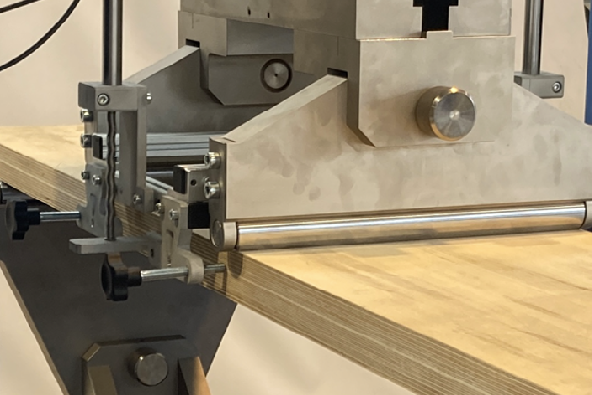

Bending tests of wood are a key tool for assessing its mechanical properties and behavior under various loading conditions. These tests allow engineers and designers to obtain important information about the strength, elasticity and modulus of elasticity of wood, which is essential for the proper design and construction of wooden structures. Here’s a look at wood bending tests and what they mean.3-point and 4-point bending: wood bending tests are usually performed using 3-point or 4-point bending. In 3-point bending, a force is applied to the wood specimen midway between two supports, while in 4-point bending, two forces are applied at opposite ends of the specimen with two supports in the middle. This difference in test geometry can affect the results and allows different information about the behavior of the wood to be obtained.Modulus of elasticity: one of the key parameters that are determined in bending tests of wood is the modulus of elasticity (also called modulus of elasticity). This parameter indicates the wood’s ability to resist deformation when a bending load is applied. Higher values of the modulus of elasticity indicate greater stiffness of the material and the ability to withstand bending loads.Practical significance: in practice, wood bending tests are invaluable to engineers and designers in the design and construction of wood structures such as beams, beams, parquets, wooden floors and more. The obtained information on the modulus of elasticity and bending resistance of wood allows for the correct dimensioning of structural elements and ensures safety, stability and long-term reliability.

Wood bending tests are usually performed according to standardized procedures and regulatory requirements that ensure consistent and accurate results. These standards establish testing conditions, sample geometry, measurement methods and other parameters that are important for the correct performance of tests and interpretation of results.Bending tests of wood are an essential tool for understanding its mechanical properties and behavior under various loading conditions. These tests make it possible to obtain important information about the modulus of elasticity, resistance and stiffness of wood, which is essential for the successful design and construction of wooden structures in the construction, furniture and other industries.

Recommended testing machines for wood bending tests

Electromechanical and servo-hydraulic testing machines are the right choice…

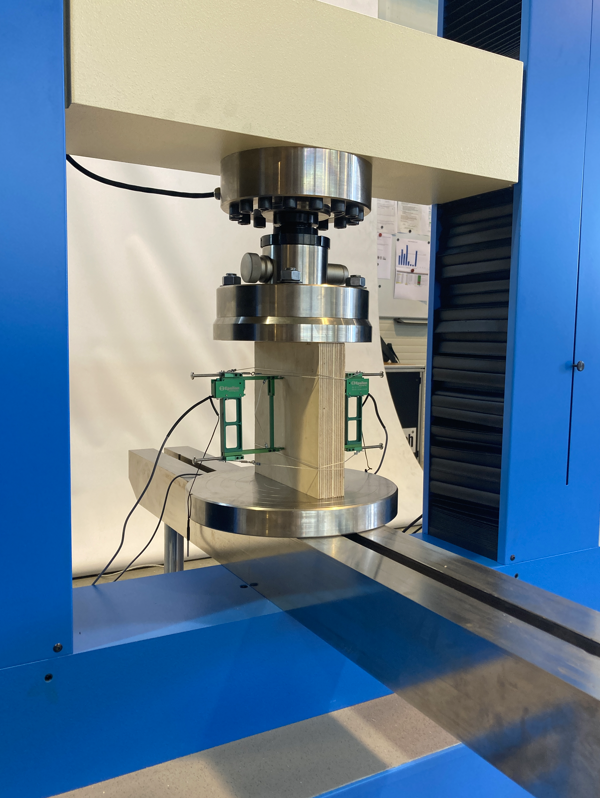

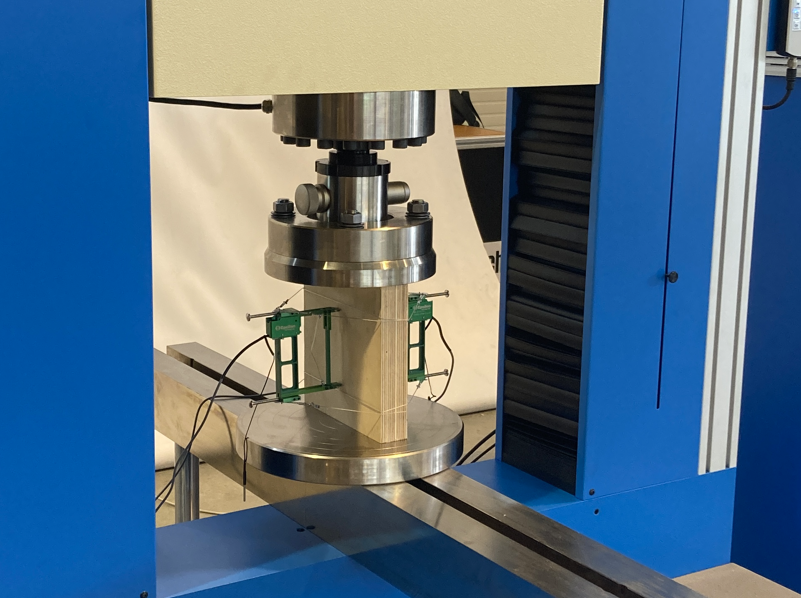

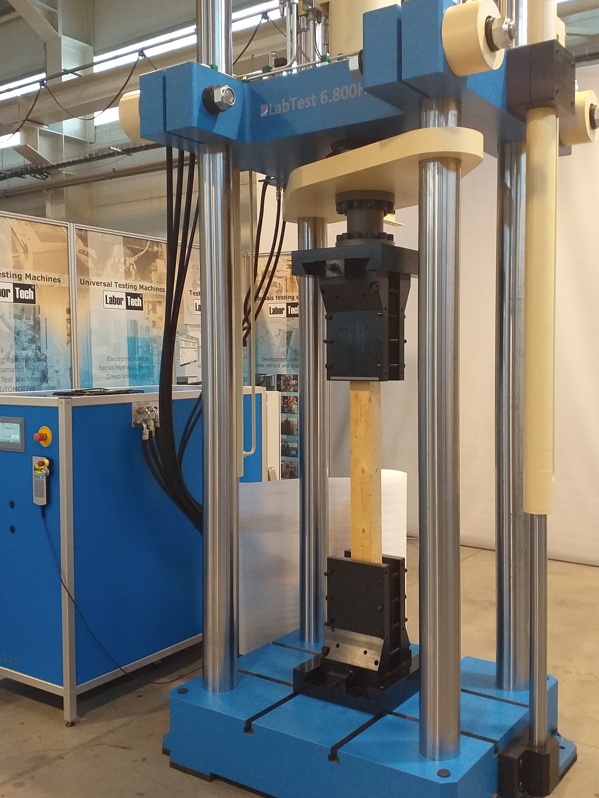

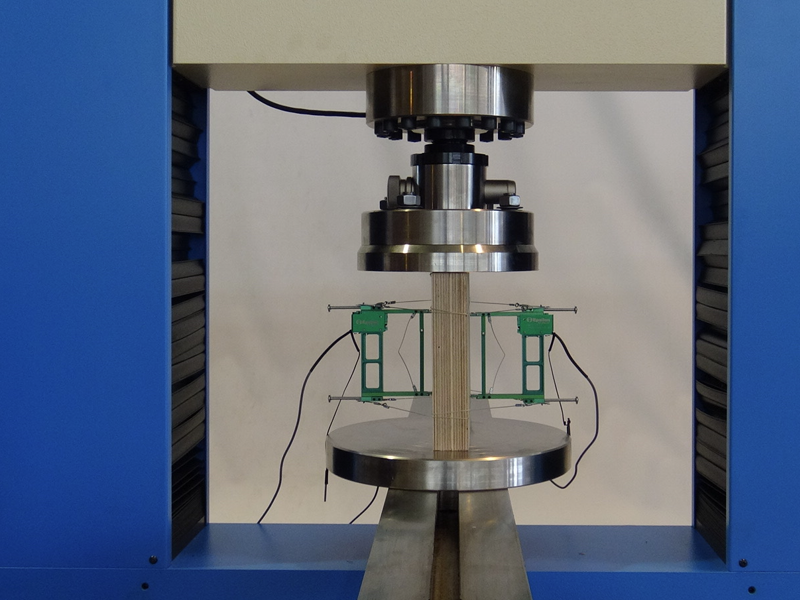

PRESSURE TESTS OF WOOD

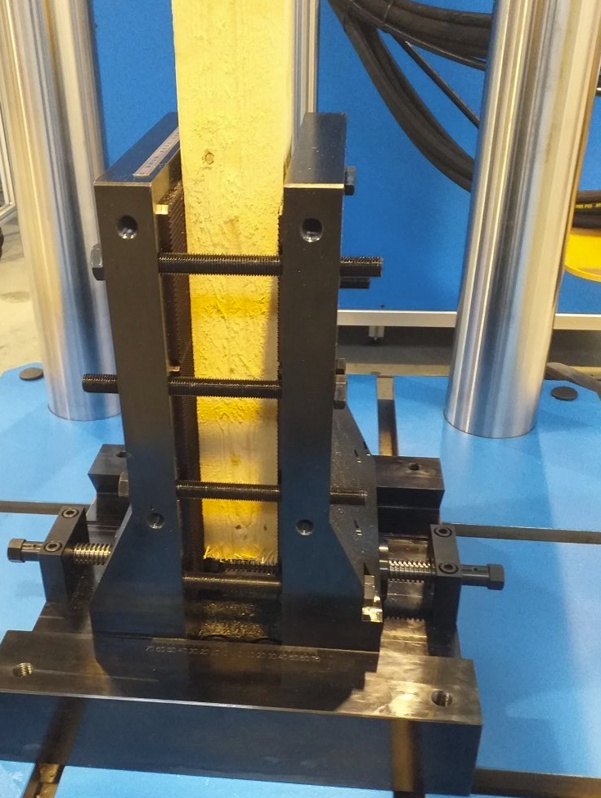

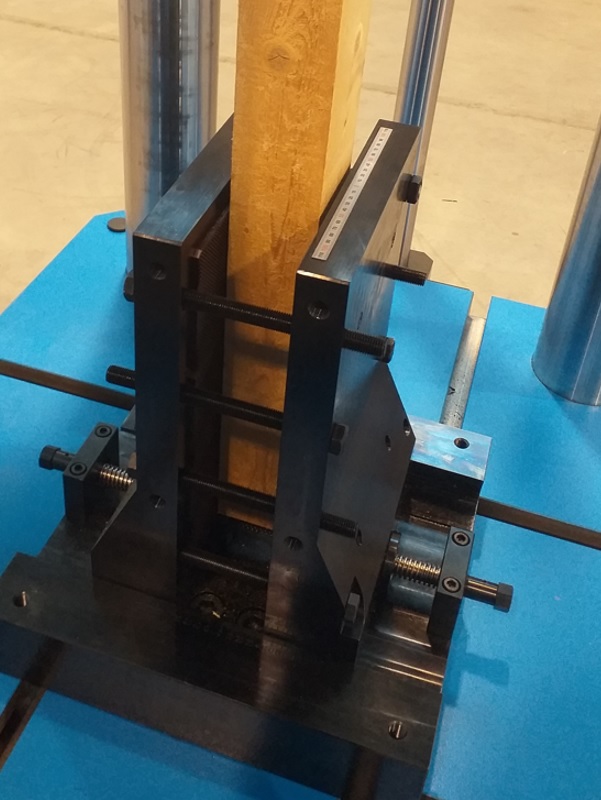

The compression test of wood is necessary to assess the resistance of wood to compressive forces, which is especially crucial in the field of construction, where materials are under significant compressive loads, for example in the construction of columns, beams and supports. This test makes it possible to determine the behavior of the material under compressive loads and provides important information for engineering and construction applications. Compression testing of wood is usually carried out according to standardized procedures, using compression fixtures and extensometers including normative requirements that ensure consistent and accurate results. These standards establish testing conditions, sample geometry, measurement methods and other parameters that are important for the correct performance of tests and interpretation of results.

Compression tests of wood are an essential tool for understanding its mechanical properties and behavior under compressive loads. These tests allow engineers and designers to obtain important information about the strength, stiffness and durability of wood, which is crucial for the correct design and construction of wooden structures in construction and industry.

Recommended testing machines designed for pressure testing of wood

Electromechanical and servo-hydraulic testing machines are the right choice…

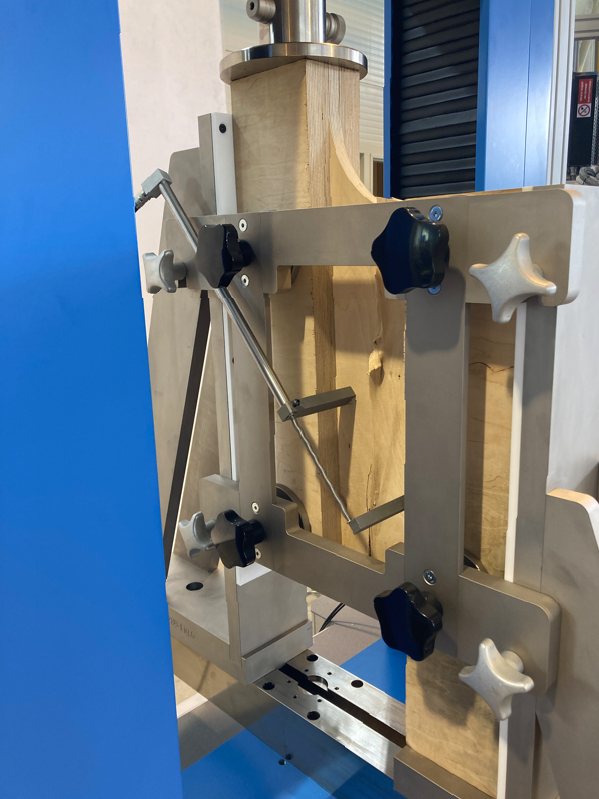

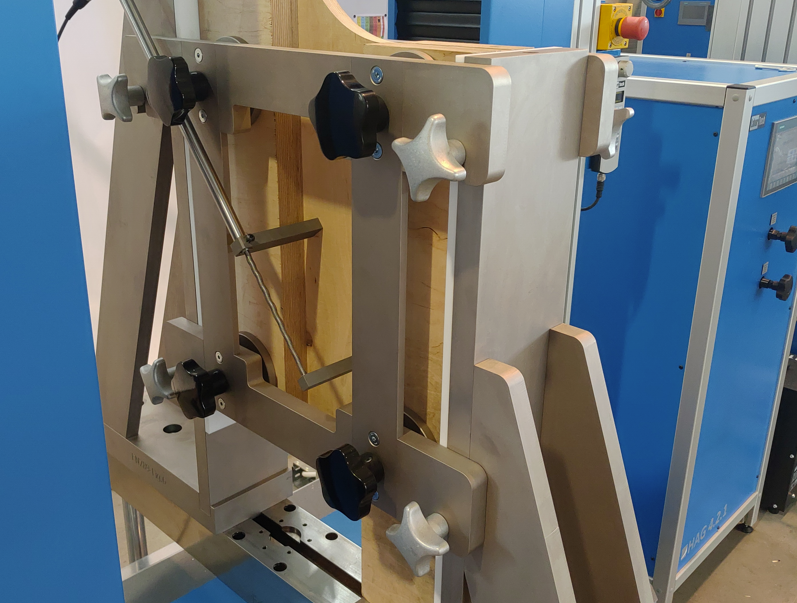

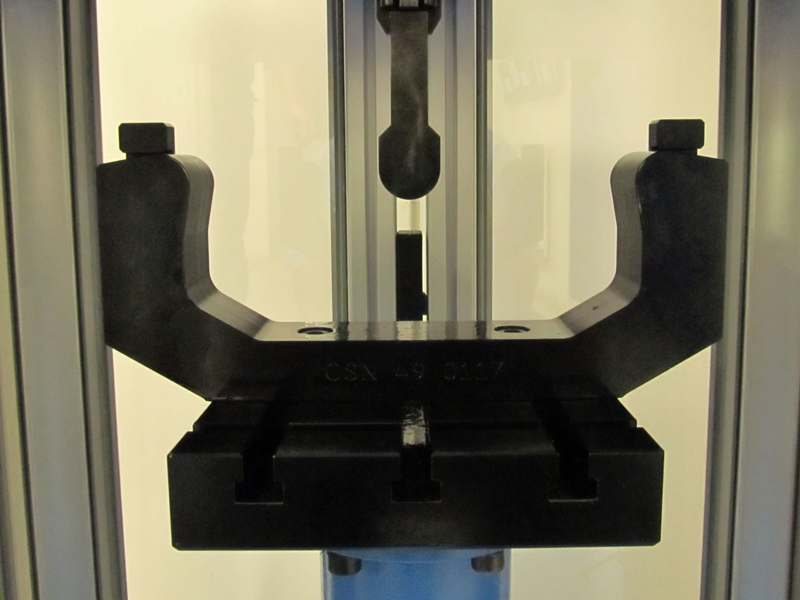

SHEAR TEST OF WOOD

Cutting wood testing is a necessary step in assessing the mechanical properties of this important material. It provides important information about the wood’s resistance to shear forces and its ability to resist deformation under the weight of the load. LABORTECH offers state-of-the-art testing machines with integrated fixtures according to the relevant standards that allow this crucial test to be performed with precision and reliability.The significance of the cutting test: the mechanical properties of wood have a major impact on its use in construction, furniture and other industries. The cut test provides information on the strength, stiffness and flexibility of the wood, which is crucial for design and construction. Understanding these properties allows engineers and designers to more effectively design and dimension structures that will resist shear loads. Norms and standards: testing machines from LABORTECH meet the latest norms and standards for cutting wood testing. This includes, for example, ASTM D198 or ISO 13061-3:2014. This compliance with standards ensures that the tests performed are in accordance with the prescribed procedures and that the data obtained is relevant and usable.

Testing wood in a cut is a key step in assessing its mechanical properties. Testing machines from LABORTECH with integrated fixtures according to the given standards allow this test to be carried out with precision and reliability, which is essential for the correct design and construction of wooden structures and products. Thanks to them, engineers are able to effectively design and dimension structures that meet the required standards and requirements for strength and safety.

Recommended testing machines designed for cutting wood tests

Electromechanical and servo-hydraulic testing machines are the right choice…

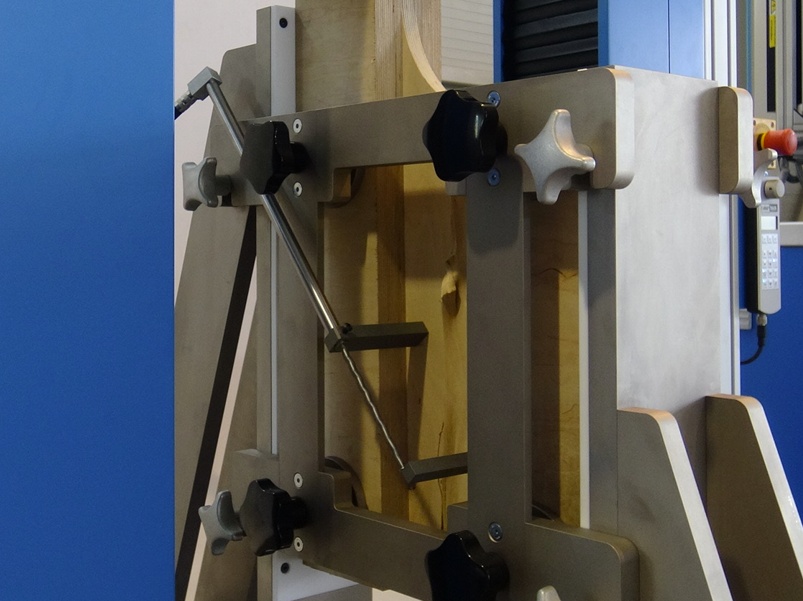

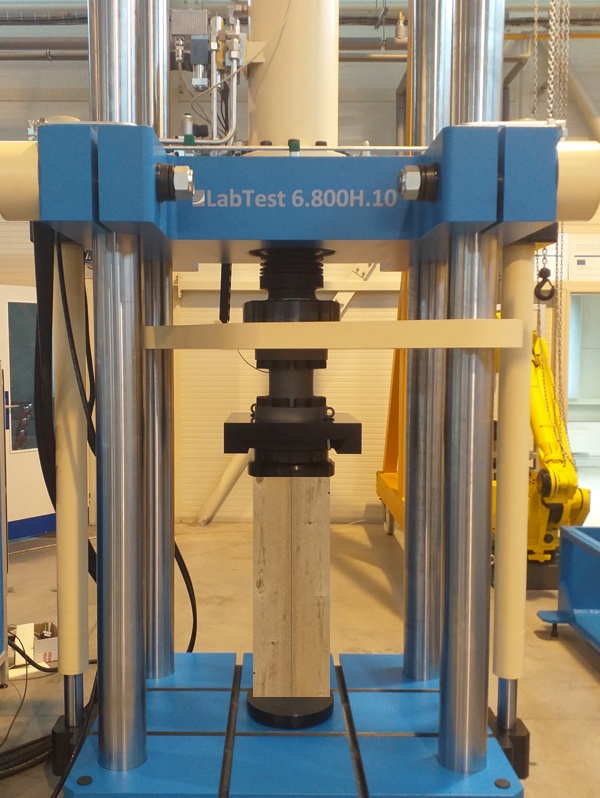

CYCLIC LOADING OF WOOD

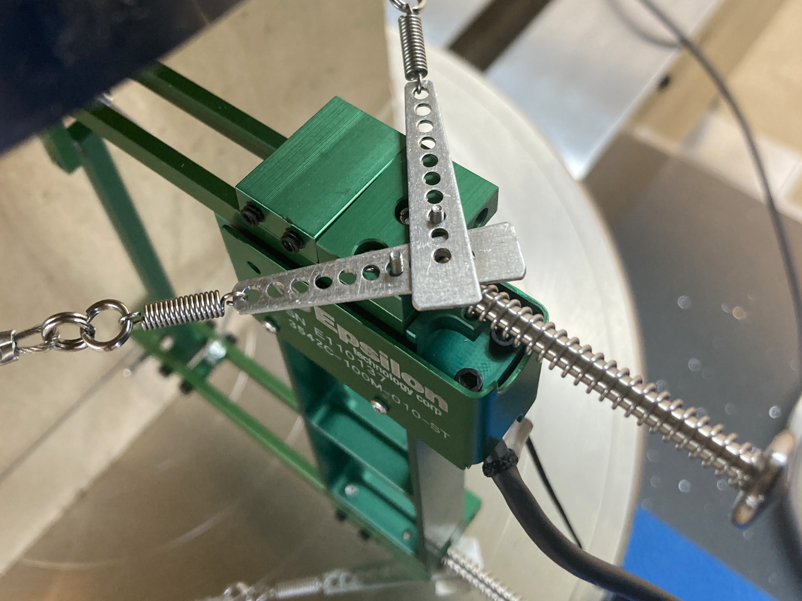

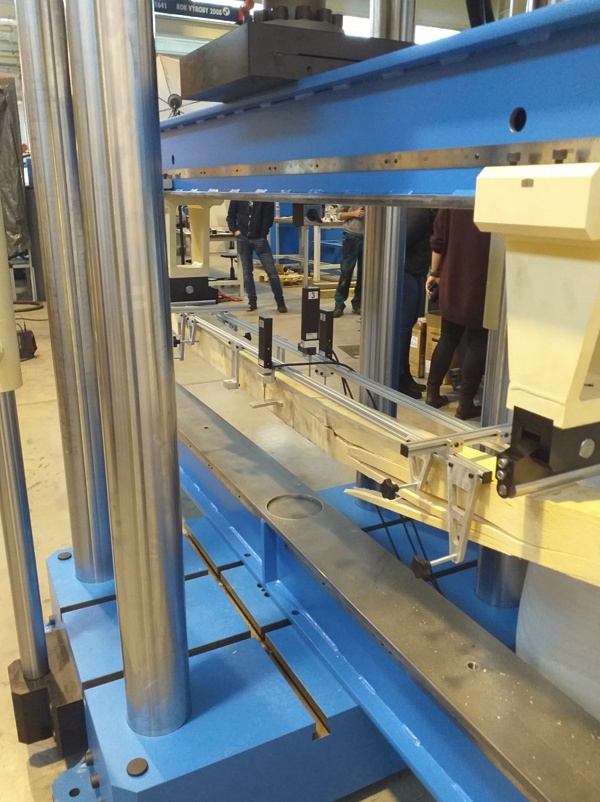

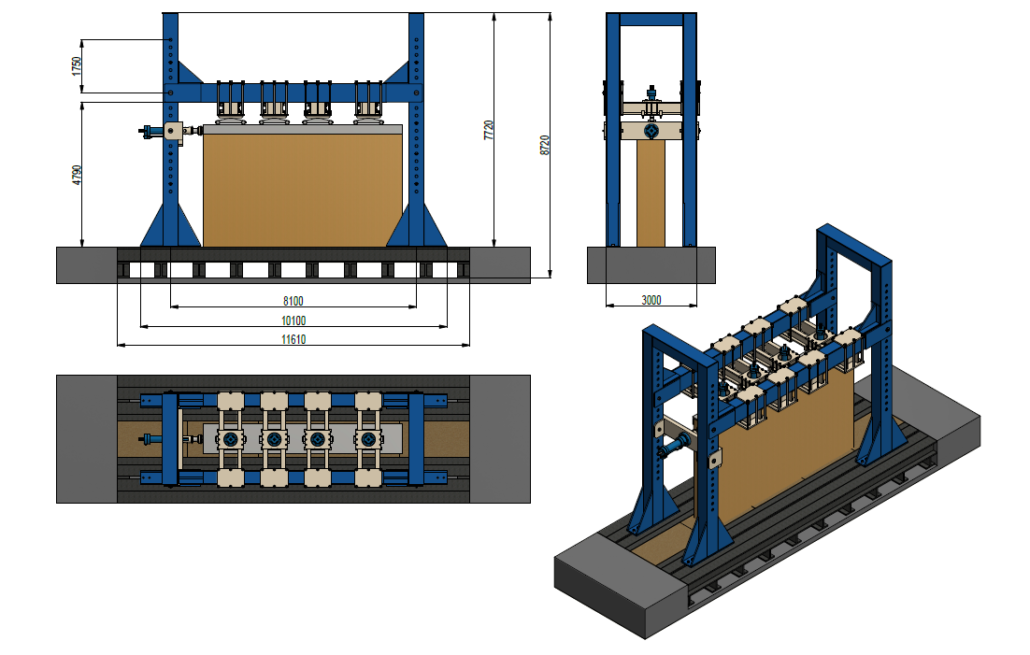

The cyclic wood test is a special type of test designed to assess the behavior of wood under repeated loading. This type of test is necessary to understand how wood reacts to repeated loading, which is especially important for the construction of bridges, buildings and other structures that are subjected to cyclic stress.Testing possibilities: servo-hydraulic and electrodynamic testing machines or H.10 series test benches from LABORTECH enable testing of large glued beams according to ČSN EN 12512 and joint tests according to ČSN EN 12512 or ISO 21581. These standards provide precise procedures for carrying out cyclic tests of wood and establish requirements for performance and reliability of the material. These standards specify how tests should be performed, what criteria should be met and what results should be obtained. This makes the test results relevant and applicable for structural design and construction.

Cyclic testing of wood is a key step in assessing its behavior under repeated loading. Servo-hydraulic and electrodynamic testing machines and test benches from LABORTECH provide an ideal solution for performing these tests and enable testing of large glued beams and joints according to the relevant standards. Thanks to them, engineers are able to better understand the behavior of wood and design structures that meet the requirements for strength and reliability.

Recommended test machines designed for cyclic stress tests

Cyclic loading of wood without limitation of dimensions and strength…

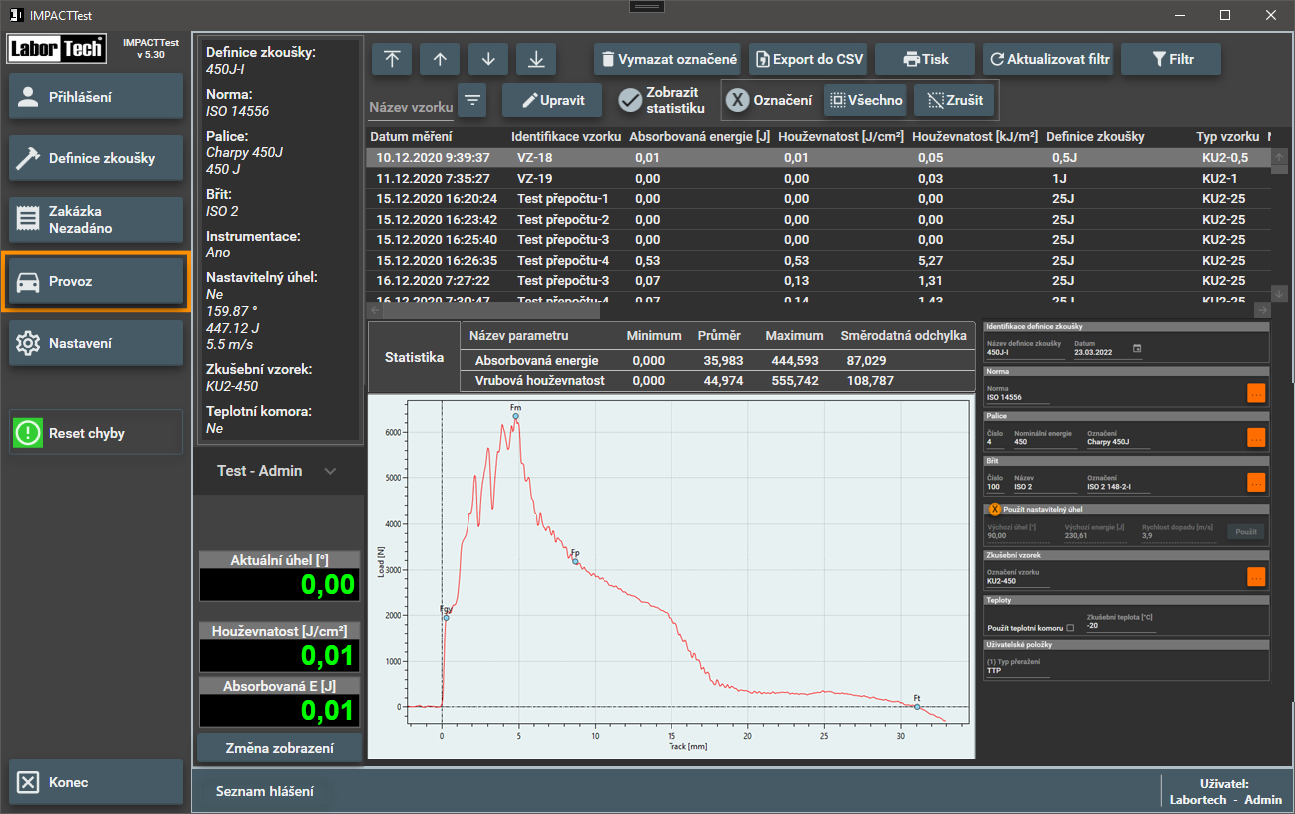

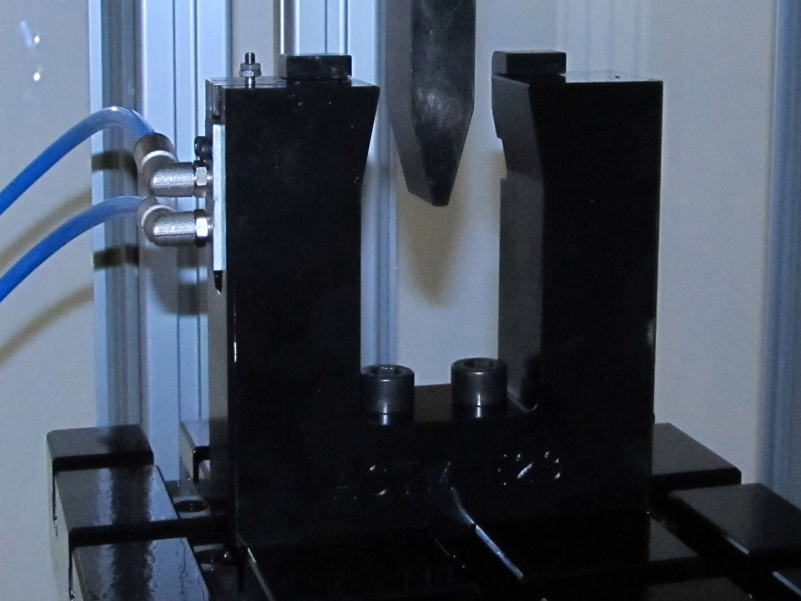

IMPACT TEST OF WOOD MATERIALS

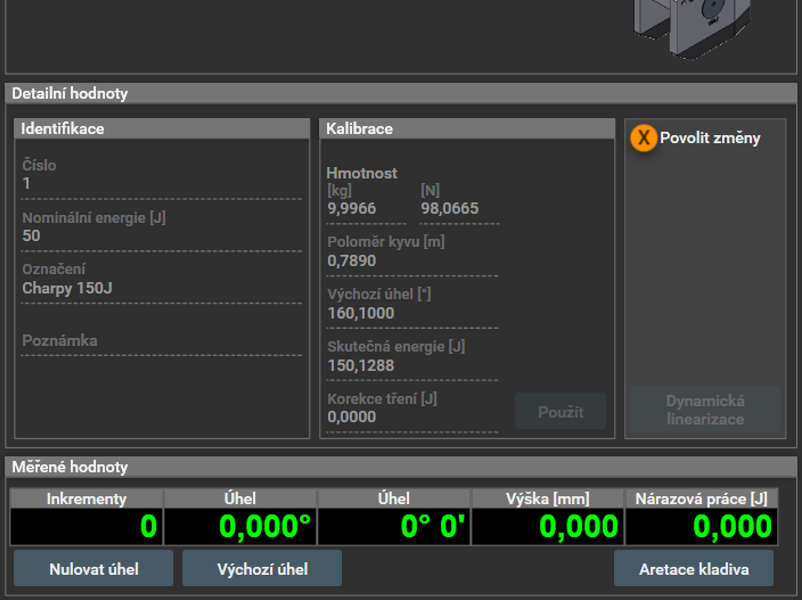

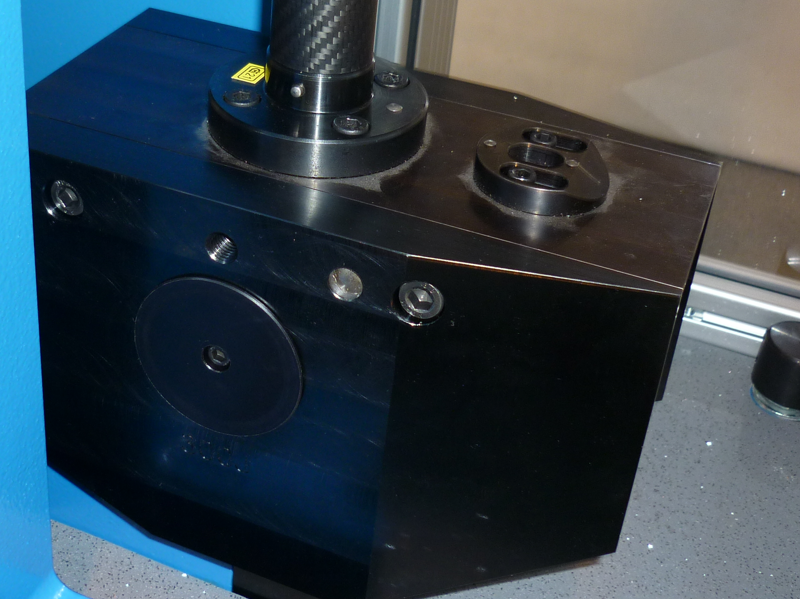

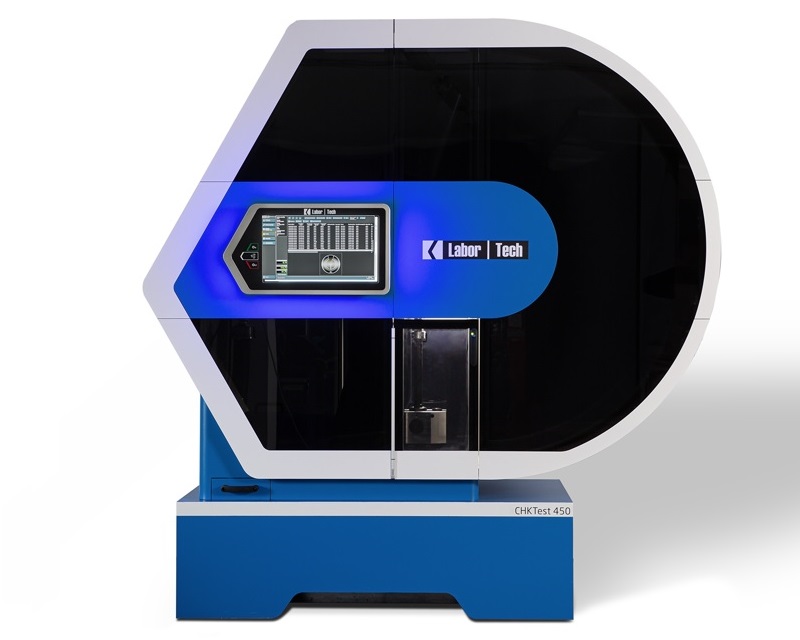

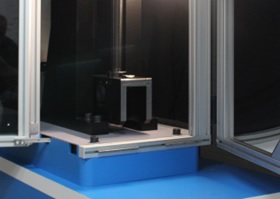

LABORTECH, a leading manufacturer of testing machines, is known for its cutting-edge technology for impact testing wooden materials. By wood toughness we mean the wood’s resistance to dynamic (impact) stress, which is determined by a puncture test. In the impact test, a pendulum hammer strikes the center of the test specimen from a constant height. We determine the energy required to break a body under the action of a dynamic load. By the appearance of the quarry, we can determine the quality of the wood. The toughness of wood is strongly influenced by wood defects, wood drying at higher temperatures, forced impregnation, etc.

Díky přesným testovacím strojům od LABORTECH jsou výrobci schopni provádět tyto klíčové testy s vysokou přesností a spolehlivostí, což je nezbytné pro zajištění jakosti – kvality dřeva a dřevěných produktů ve stavebnictví.

Recommended testing machines designed for impact tests of wood …

We will be happy to advise you on the right choice of machine…

Contact

LABORTECH s.r.o. , Rolnická 1534/130a, 747 05 Opava, Czech Republic

Research & Development

Reducing energy intensity We increase your productivity Development and implementation

News & Events